Based on the conditions of perception and taking into account the functional features of the products, it is possible to identify the main groups of compositional techniques characteristic of modern furniture.

1. Front-plane composition, designed for the visibility of the product on the one hand. This technique is typical for housing products with blind front surfaces: for built-in and mobile cabinets.

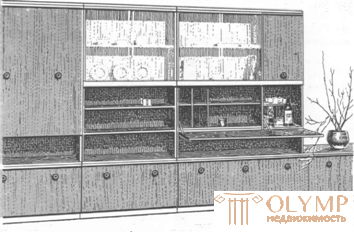

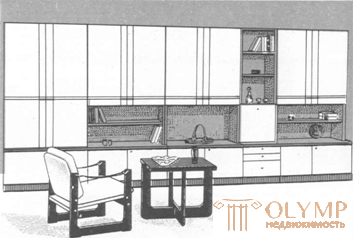

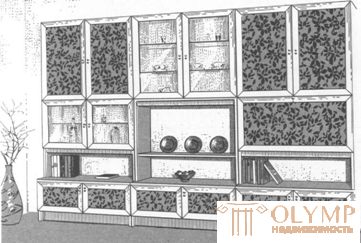

2. Frontal-spatial composition, designed for the same conditions of perception, as the previous one, but having spatial elements (open shelves, glazed compartments, protruding and recessed elements, etc.). This technique is widely used in modern practice to solve household and public furniture: cabinets and racks; kitchen furniture; bar counters in cafes and restaurants; slides for equipment stores, etc.

3. Volumetric composition, designed for the perception of the product from various sides and for its free location in the room, characteristic of tables, chairs, armchairs, etc.

The main means of expression of the frontal-plane composition are vertical and horizontal divisions, which reflect the internal or structural structure of the furniture item. This composition can be: symmetrical, which is achieved by the equality of elements relative to the vertical axis; rhythmic when repeating the same elements; asymmetric, when the unity of the composition is achieved by balancing its parts.

When the front-plane composition, which is especially characteristic of embedded furniture products, the role of face accessories, the placement and nature of the solution of which are a strong artistic tool that emphasizes the general idea of a particular product, is extremely increasing.

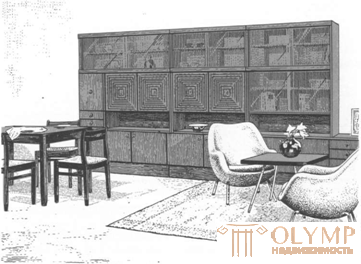

Modern practice is characterized by a search for new artistic means, including an increase in the expressiveness of cabinet furniture. Thus, a set of cabinet furniture IB-1300 attracts originality of decorative and plastic solutions (Fig. 1). Overhead profiles of door planes in the form of elongated frames in combination with square ornamented handles create a peculiar rhythmic pattern and enrich the shape.

Fig. 1. Application of overhead frame profiles (set of cabinet furniture IB-1300, the author of the project T. E. Tikhomirova, VKPTIM)

The color scheme is based on the contrast of saturated colors (red, green) and white color of decorative plates. There is also a version of a monochrome background coating and decorative overlays.

In products with a dominant front plane, vertical or horizontal divisions are emphasized. In recent years, there has been a return to placing the mirror on the front, outer side of the cabinet door. This can be explained by utilitarian reasons and the desire to diversify products.

The frontal-plane composition can also include the placement of front surfaces in different planes or at different levels, which is typical of kitchen furniture, where horizontal or vertical divisions take on special significance.

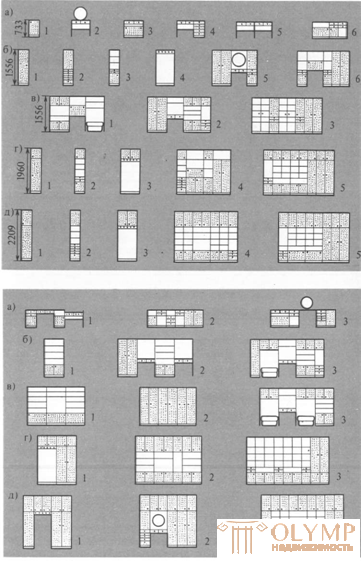

With equal functional and utilitarian qualities, a large variety of composite solutions of individual products and their groups is possible. This is especially pronounced in the variety of techniques of the front-spatial composition.

Fig. 2. Creation of various compositions (developed by Ukrgipro-mebelprom): a - workers and toilet tables; b - combined cabinets; in - cabinets for various purposes; g, d - cabinets with mezzanine compartments

In fig. 2 shows the options for assembling the universal folding furniture developed by the Ukr-Gipromebelprom scientific-design furniture and fittings production association and the Ukr-Gipromebel furniture Ukrainian State Institute for Furniture and Joinery Design. From a limited set of parts, you can create an unlimited number of combinations that differ not only in purpose and internal device, but also in compositional techniques: low products of various purposes; cabinets, the composition of which is based on a combination of different numbers of open and deaf volumes.

Variance is one of the most characteristic features of modern furniture. However, the functional and aesthetic advantages of various options suggest a certain stability of the compositional techniques even in such a group of furniture, which can be attributed to the front-spatial. The following illustrations show the characteristic techniques of the front-spatial composition used in domestic and foreign practice for cabinets for various purposes.

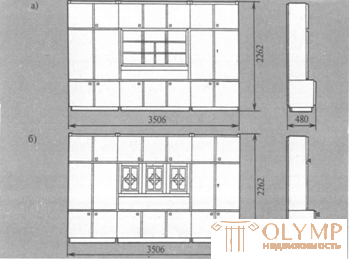

In fig. Figure 3 shows cabinets of a symmetrical composition, built on a combination of blind flanking lower and upper elements with a glazed central section and accentuating lining. The static composition is emphasized by plasticity of the protruding lower blind sections on a solid base. In the closet revealed plastic due to a deeper bottom and section for storing the dress. The introduction of deaf sections and a solid base significantly improves the composition of the product, as it creates a quieter surface with a clearly defined center formed by glazed sections.

The considered examples allow to note that asymmetric balanced techniques of frontal-spatial composition have received the greatest application. However, these techniques are the most difficult to perform and require great skill of the designer.

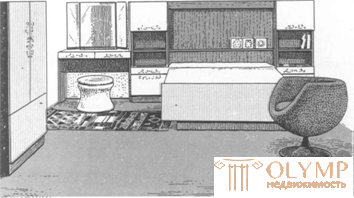

Beds can also be attributed to front-spatial furniture compositions, especially models with a developed headboard, which have become popular in recent years.

In this respect, the works presented at the Third All-Union competition of the best samples of mass production for new types of apartments, held in 1974-1975, are indicative. in Moscow at VDNKh USSR. Almost all the sleeping places in the marked sets of bedrooms had a developed headboard. Such a headboard is also characteristic of the set of furniture for the bedroom “Autumn”, developed by the All-Union Design, Design and Technological Institute of Furniture (head of the group of authors Yu.V. Sluchevsky) of the USSR Ministry of Industry.

In the set of "Birch", developed by the design office of furniture design MMSK-1 (the head of the author's group S. A. Selivanov), the bedside unit is solved asymmetrically, with deaf lower and one of the side elements and a strongly revealed horizontal recessed niche, combining small open shelves, doors, etc.

Abroad, examples of frontal-spatial solutions of bedside units are also quite widely represented (Fig. 60).

Fig. 3. An example of a symmetrical solution to the front-spatial composition of cabinets (set of sectional furniture N ° 118, developed by Ukr-Gipromebelprom): a - with smooth glass; b - with patterned glass

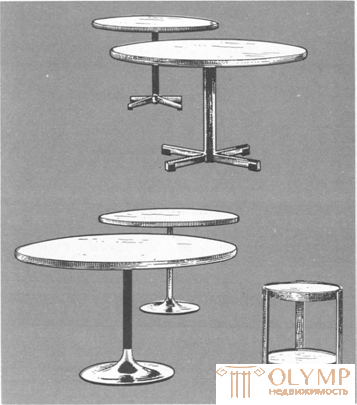

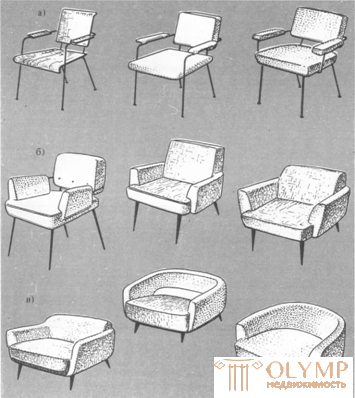

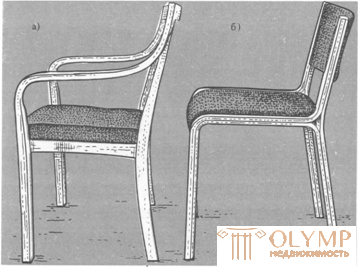

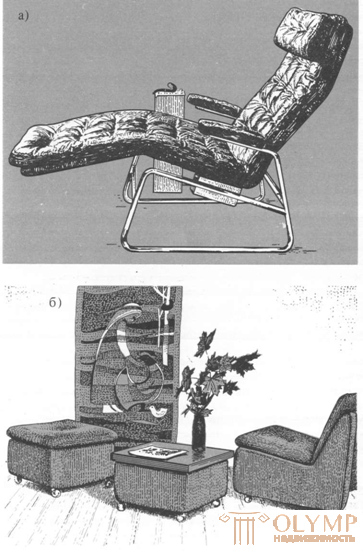

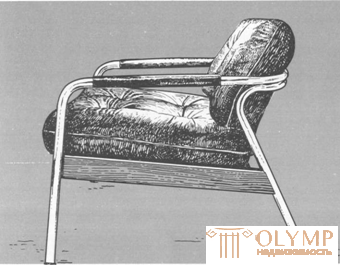

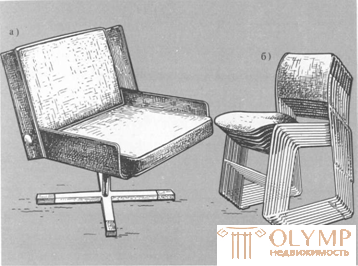

The main methods of volumetric composition can be classified depending on the spatial distribution of the volume elements and the position of the main one. There are compositions with a vertical axis of symmetry, i.e. with a lack of orientation towards any prevailing point of view, central compositions and compositions with a vertical plane, providing for a certain point of view. The first, small, group consists mainly of round and square-shaped tables, stools, serving trolleys, etc. (Fig. 4). The second group may include compositional schemes of chairs, armchairs, sofas, and rectangular tables.

The considered techniques are closely related to the most important compositional means — tectonics (Fig. 5), that is, to identify and use for artistic purposes the constructive structure of the product. The constructive forms that make up a furniture product, like the forms of a building, become tectonic when they are transformed into a single system that reveals the main features of this design and at the same time the main artistic idea embedded in the product. Tectonics is associated with plastic and through it with the proper organization of the material. The key to the correct tectonic decision of a furniture product is to identify the operation of the structure and the correspondence between the load and the support.

Fig. 4. Examples of centric volumetric compositions with a vertical axis of symmetry (tables and serving trolley)

Tectonic patterns appear specifically depending on the functional and structural conditions and aesthetic requirements. They act in the relationship of design, material and form, in the ratio of differently working parts of the whole, in the features of plastic processing of the form. In the process of a long evolution of product forms, the general patterns of tectonics associated with the features of the functioning of objects were determined.

Fig. 5. An example of a tectonic solution of furniture for sitting: a - spatial forms of chairs; b - intermediate forms of chairs from spatial to compact; in - compact form

In the form of static objects, their stability, weight, materiality, and durability are primarily expressed. For example, in the forms of the table, the chair reflects the principle of operation of a single-span frame: the form of supports tapering downwards and rigidly connected to the deadbolt corresponds to the change in forces from bending moments. The shape of these objects can be modified depending on the specific purpose and material, but the meaning of the constructive work of a single-span frame should not be disturbed.

An example of the spatial construction of chairs is the shell design proposed by the architects Hérôte Saarinen and Charles Imes, which radically changed the tectonics of furniture. Artistic characteristics of structural elements are associated with tectonics, which, depending on the impression, are divided into “heavy” and “light”, “massive” and “spatial”, “static” and “dynamic”. The impression of gravity is caused by simple, close to square proportions of furniture products and their elements, exaggerated sections of parts, for example legs. Elongated proportions, thin vertical relief, lightweight sections of details contribute to the impression of lightness.

None of the factors affecting the artistic decision of furniture, does not possess such force as the materials used. This is natural, since it is the material, its design capabilities, which are most fully revealed with various processing methods, its plastic, texture, color, determine the artistic form of the furniture product, create its appearance.

According to the materials used, modern furniture is divided into three main groups: furniture using wood; furniture with the use of metal; furniture with the use of polymeric materials.

For the domestic furniture industry in the application of structural and finishing materials is characterized by the solution of three main tasks: increasing the utilization of wood; the use of new progressive materials; the use of new ways of artistic decoration.

To save solid wood, it is envisaged to expand the use of chipboard and fibreboard in constructions. A positive factor is the use of gnu-glued parts and veneer elements for cabinet and lattice furniture. The unification of sizes of bent-glued elements for chairs, drawers and semi-drawers was carried out in order to organize their centralized production. Considerable attention is paid to the development and use of progressive materials in furniture designs, including plastics.

Below are some of the artistic features of modern furniture, depending on the materials used.

Due to its positive qualities (warmth, variety of patterns, colors, processing possibilities), wood continues to be the most common constructive and finishing material for the manufacture of furniture, especially designed for residential apartments.

Domestic practice has centuries-old traditions of using wood in architecture, interior decoration, making furniture and other household items. Artistic woodworking in Russian art is an exceptional phenomenon. The reason for this is a number of interacting natural, economic, spiritual factors. In Russia, woodworking has long been common. The works of Russian folk furniture makers have always been distinguished by high artistic quality and originality. Widely used carving, turning, painting, mosaic and other types of artistic wood processing. Sometimes in one product combined turning and threading; turning, carving and painting or painting; gilding, mosaic, inlay, decorative veneering, various types of carving: three-edged and contoured, flat-relief, etc.

The drawing and methods of its implementation also depend on the type of wood and its features. Soft rocks that are easy to carve include linden, pine, poplar, aspen, alder, spruce, larch, and solid - oak, maple, birch, boxwood, yew, palm, walnut, cedar, beech, hornbeam. Linden, aspen, maple, elm, pear, apple, walnut have a homogeneous structure of the wood, so the carving on them is distinguished by plasticity of forms with extremely precise detailing even in small figure. Oak carving has a somewhat dry character, but the outline of the pattern clearly protrudes in it, which makes it possible to achieve subtlety in the execution of flat reliefs. In pear carving, also of hard rock, soft play of light and shadow is achieved. All breeds can be used for threading and turning, but they should be selected taking into account the nature of the work being performed, the purpose of the object, the pattern and the processing technique.

Wood and wood materials continue to be one of the most common structural and finishing materials used in modern furniture. However, the interpretation of wood in the design of furniture has artistic features. It may be noted the following of them.

The most common use of wood as a finishing and facing material, especially for furniture. Here the leading artistic tool is color and texture. The most commonly used natural wood pattern. In the set of furniture for a one-room apartment, the clearly identified vertical texture of the facing of the cabinet doors corresponds to the overall composition of the set and emphasizes the vertical proportions of the main elements (Fig. 6).

Fig. 6. An example of using a vertical texture pattern for facing cabinet doors (a set of furniture for a one-room apartment BN-123-00, author of the project V. M. Turgenev, VKPTIM)

An example of a modern approach to the treatment of wood in the decision of cabinet furniture can serve as cabinet furniture in a set for a two-room apartment (Fig. 64). The group of case products has unified front panel elements, which makes it possible to assemble them into a single unit along the front. The architectural feature of body products is the upper lightweight belt consisting of compartments with shelves behind sliding glass doors. The figured set of planed veneer on the doors of the middle belt of products is used as a decorative element. An additional element of the decor is the front metal fittings with stamped lining.

Thus, a characteristic artistic tool used in wooden furniture is to identify the texture of the front surfaces. The combination of the vertical texture of the doors with the horizontal texture of the drawers is the leading theme of many furniture products, such as cabinets. Often, the artistic appearance of such relatively simple products, such as a sideboard and stand, is largely determined by the texture of the front surfaces. Drawing wood furniture and furnishings can become the leading artistic theme of the interior as a whole.

Artificial materials that truly imitate the color and pattern of wood are also used as facing materials in modern practice.

“Perhaps, we have never seen such a large number of examples of imitation furniture decoration“ for wood ”at any furniture exhibition, which was proposed by the participants of the Third Competition. Imitation has been known to us for a long time; we can recall various methods of imitative finishing of the period of the 1950s – 1960s — airbrushing and knurling. The low artistic and taste level of most attempts of that time to mask the lack of good veneer wood, which gave rise to a negative attitude to the very principle of obtaining expensive effect with cheap means, remained in memory. Но время шло, технологи и химики, не взирая на дискуссии с искусствоведами, продолжали совершенствовать отделку мебели, в том числе и имитационную, к этой работе подключились полиграфисты. Результаты такого комплексного «наступления» не замедлили сказаться, причем на первых порах даже в курьезной форме: опытные члены художественных советов начали принимать бумагу за древесину.

Fig. 7. Пример использования фигурного набора строганого шпона на дверцах (набор мебели для двухкомнатной квартиры БН-118-00, авюр проекта Н. 6. Тихонова, ВГЖТИМ)

Сегодня существует несколько технологически совершенных видов имитационной отделки поверхностей: оклейка бумагой с напечатанной на ней репродукцией текстуры древесины; оклейка синтетической пленкой, которой придан эффект не только текстуры, но и фактуры как бы пористой древесины; наконец, рисунок текстуры прямослойной древесины может быть нанесен при механизированной отделке прямо на грунтовую поверхность щита. Эти виды имитации были с успехом использованы проектировщиками ВПКТИМа, ММСК-1, конструкторских бюро Латвии и Литвы. …Современная имитационная отделка очень близка к натуральной древесине, почти до «потребного» сходства, либо предлагает внешний эффект, столь органично вытекающий из существа технологии, что его следует оценивать уже не как попытку повторить природу, а как возникновение принципиально нового материала, полноценного и художественно и технически. Привычная и излюбленная характерность древесины (масштаб и игра рисунка) при этом сохраняется, но проявляется в новом качестве».

В современной мебели необходимо отметить еще одну художественную трактовку древесины: подход к ней как к ценному декоративному элементу декора мебельного изделия, способствующего художественному противопоставлению материалов. Так, цветовое решение набора мебели для спальной комнаты БН-183 (автор проекта Л. А. Портной, ВПКТИМ) строится на четком выделении и цветовой поддержке горизонтальных членений-поясов: плинтусов, выдвижных ящиков и карнизов, объединяющих и организующих композицию набора. Эти го ризонтальные пояса и плоскости низких корпусных изделий облицованы тонированным щитом натуральной древесины, например красного дерева; вертикальные плоскости корпусных изделий отделаны эмалью светлого тона.

Сочетание материалов дополняют обтянутые тисненой кожей кроватные спинки и пуф, которые придают интерьеру комфортабельность, мягкость и теплоту.

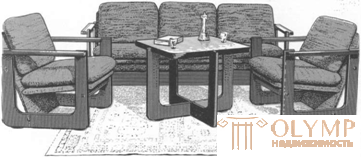

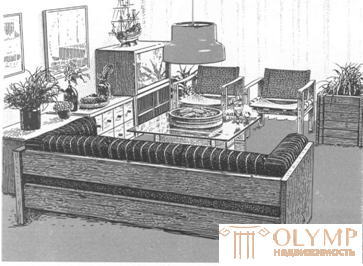

В современной мебели широко применяются клееные элементы. Примером может служить гарнитур «Уют», состоящий из дивана, двух кресел и стола и предназначенный для оборудования зон отдыха в жилых помещениях (рис. 8). Применение унифицированных клееных элементов в боковинах дивана, кресел и в основании стопа создают единое архитектурно-художественное решение всего набора, который отличается высокой комфортабельностью, оригинальной конструкцией и благоприятными эстетическими качествами.

Fig. 8. Пример мебели с клееными элементами (автор проекта О. 8. Кузнецова. ВПКТИМ)

Fig. 9. Пример гнутоклееной конструкции стула: а — Швеция; б — ФРГ

Клееные конструкции в мебели широко применяются и в зарубежной практике. In fig. 66 показаны стулья с применением клееных элементов, разработанных в Швеции и ФРГ. Для клееной мебели характерна пластичность форм, выявленная работа конструктивных элементов, легкость пропорций изделия.

Одним из наиболее известных примеров использования клееных конструкций является серия мебели, созданная известным финским архитектором Альваром Аальто и выпускаемая финской фирмой «Артек». Серия включает широкий перечень изделий, предназначенных для оборудования жилых и общественных помещений: полки для книг и скамьи, комоды й кабинеты, кресла, стулья и табуреты, обеденные столы круглые, письменные и специальные столы. Всю серию отличают чистота и лаконичность художественного замысла, оригинальность конструкции, а также укрупненный масштаб деталей.

Fig. 10. Пример деревянной мебели традиционной формы (Швеция)

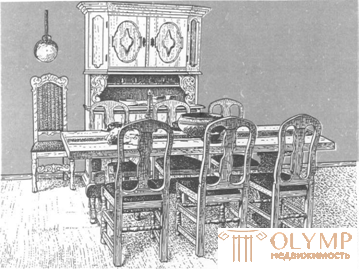

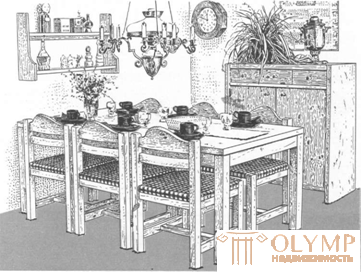

Speaking about the use of artistic possibilities of wood in modern furniture, it is necessary to mention one more aspect of this problem. In domestic and foreign practice, the creation of wooden furniture in traditional and folk forms continues. Of course, these are not samples of mass production, but of individual production. However, furniture (separate groups of objects), which is distinguished by its folk character, is very common in modern residential interiors and in mass public buildings: cafes and restaurants. Forms of traditional and folk furniture made of wood are often used in our country (especially in the Baltic republics), in the Scandinavian and other countries.

In fig.10, 11, 12 shows examples of Swedish furniture for the equipment of a place for eating and resting areas. Here is a repetition of architectural and constructive schemes of the past, the use of sufficiently powerful divisions, the preservation of all or almost all of the traditional structural elements, and the introduction of decorative elements or bright color spots (for example, the color of the upholstery of the seat) characteristic of modern furniture.

Fig. 11. An example of wooden furniture of national form (Sweden)

Considering the numerous examples of wooden furniture made in folk traditions, we can note its most characteristic features: first, the use of traditional wooden structures; secondly, some excess material, some exaggeration, not caused by constructive-functional sections of the elements, more enlarged scale of products; thirdly, the widespread use of decorative elements, including carving.

In modern practice, very favorable artistic results can be obtained from the extensive use of folk furniture traditions.

Plastics and polymers have good operational (hygienic) and aesthetic (lightness, plasticity, expressiveness of form) qualities. In addition, they provide a large economic effect, which is achieved by reducing the cost of manufacture and operational advantages of materials.

Fig. 12. An example of modern wooden furniture

The use of plastics in furniture allows you to save wood, labor, increase productivity of labor to diversify the architectural and artistic design of products by creating plastic forms and various colors.

Progressive is the use of synthetic veneer on the basis of resin-impregnated paper with a printed wood texture for furniture lining. The furniture industry has recently been able to use in the upholstered furniture products elastic elements made of molded sponge rubber and foam plastic on polyethers. Furniture frames are made of molded foam, polystyrene foam. Such furniture is characterized by smooth lines and a variety of forms. The examples below show the diversity of the use of polymeric materials in the domestic furniture industry.

Fig. 13. An example of using BA-15 film as a facing material (BN-153-00 set of cabinet furniture, the author of the project is B.I. Prokopenko, VKPTIM)

In modern cabinet furniture, polymeric materials are often used as a lining. Thus, a distinctive feature of the BN-153-00 set of cabinet furniture is the use of a BA-15 film (light tones) based on copolymers of vinyl chloride and vinyl acetate as a facing material for facade surfaces. The introduction of decorative profiles - the "veins" of aluminum or plastic - enlivens the surface of the doors and emphasizes the slender proportions of the main divisions of the set (Fig. 13). With a light tone of the facing of the doors, the darker tone of planed veneer of solid hardwood, which is lined with cases of products, is successfully combined.

Furniture made with the use of polymers, especially furniture for sitting, is characterized by soft plastic forms. The furniture for sitting (banquettes and an armchair), included in the bedroom suite for a three-room apartment, is made of expanded polystyrene. His sculptural features make it possible to build a composition on the basis of opposing simple rectangular and more capricious forms (Fig. 14). Front facial surfaces of products from bleached wood contribute to the creation of artistic-plane effect. At the same time, light decor imitating carving applied to the light surfaces of the facades, enriching and reviving the shapes of objects, contradicts the stylistic unity of the set.

The bench that is part of the BN-164 furniture set for a bedroom (the author of the project is V.E. Zakharov, VKPTIM) is molded from expanded polystyrene and covered with nap fabric. The soft element of the stool is made of flexible polyurethane foam or sponge rubber. The original solution to the design of the stools - the bearing of the soft element of plastic form on two solid sidewalls - allowed the author to give a sculptural character to the product. Such a bench fits well with the somewhat ascetic planes of the rest of the furniture products of the set, creating a peculiar decorative accent in the interior.

An example of products made from expanded polystyrene is a series of furniture for rest (Fig. 15). Its feature is the ability to obtain a variety of models from a number of elements formed from expanded polystyrene. One seat, two variants of the backs and three variants of figured sidewalls - elbows make it possible to assemble eight variants of chairs with high and low backs and the same two-, three-seat sofas. The optimal inclination and internal deflection of the back, repeating the curve of the back of a person sitting in a free posture, combined with soft cushions on the seat and back and wide soft elbow pads create comfortable conditions for effective rest. Pile fabric is used as upholstery. With a general favorable artistic solution of products, a pleasant plastic form, it is necessary to note a certain excessive bulkiness and massiveness.

Fig. 14. An example of the sculptural solution of the stools and chairs made of styrofoam (set of furniture BN-160-00 for a three-room apartment, the authors of the project are N. V. Tikhonov and E. S. Bocharova, VKPTIM)

Fig. 15. Examples of solving chairs: a - on a metal frame (Sweden); b - from expanded polystyrene (a series of furniture for rest, the author of the project V.N. Mironov, VKPTIM)

Another example of upholstered furniture on the frame, which is formed from expanded polystyrene in one technological cycle in the base mold, is also shown in Fig. 15. Lightweight small seats are comfortable enough due to the optimum back and seat inclinations, soft cushions on the seat and back, and an elastic base. The group fits rationally into the interior of a modern apartment: the right angle of the products in the plan makes it possible to place them near the walls in the corner, and the combined supports make it easy to move furniture, that is, to create a recreation area anywhere in the apartment. For the set, the upholstery material has been successfully chosen, the vertical texture of which contributes to visual relief and slimness of the proportions of furniture products.

With the help of removable soft pillow type elements, molded from spongy rubber and covered with furniture fabric, a series of upholstered furniture is presented, represented by four products: IB-1276-01 couch, IB-1276-02, 03, 04 sofas (the authors of the project O.V. Kuznetsova, B. N. Prokopenko, L. A. Basov, V. E. Zakharov, L. A. Tailor). Products differ in comfort, are supplied with a box for bedding, are established on spherical support. The artistic feature of the products is the use of two upholstery materials - furniture fabric and leatherette, which are covered with a sidewall and sidewall. Expressiveness and variation of products is achieved through various decorative and plastic study of the sidewalls and sides.

The traditional winged form is continued by the lounge chairs of the BI-949-00 series made of expanded polystyrene (index Ж54-1243 / 1-3, the author of the project is B. A. Vasiliev, VKPTIM). The series includes three models. Frameworks cast from expanded polystyrene. The development of the series is due to a change in the height of the backrest. Slip seals and backrests made of sponge rubber.

Armchairs have metal ball bearings. Products are distinguished by plasticity and sculptural, harmonious proportions.

An example of another product solution with the use of polymeric materials is the group of furniture for rest BN-122-00 (index HI7-382 / 1-3, the author of the project O.V. Kuznetsova, VKPTIM). The frames of the chair and the sofa are made of polystyrene, the soft elements are made of molded spongy latex. In the backs used synthetic fluff. Frames upholstered in leatherette. Products are distinguished by their original form, contrasting color matching of the frame and soft elements.

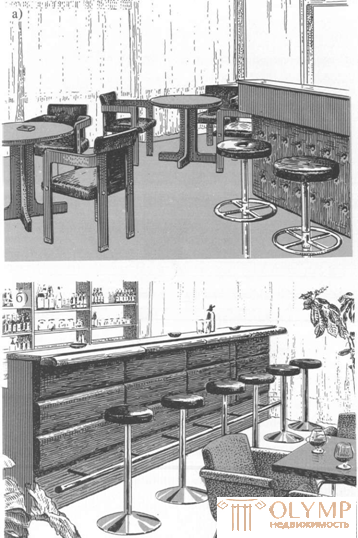

Artificial materials are widely used in the design of furniture for public buildings, including furniture for canteens, cafes and restaurants. In a set of furniture for cafes and restaurants (Fig. 73, a), artificial leather is covered with seats of stools, chairs and a bar counter, which makes it comfortable. In the decoration of products color enamel and transparent lacquer coatings on natural wood are successfully combined. The effective decorative accent is polished copper sheet, which is decorated with the legs of tables, chairs and stand bases.

Polymeric materials in furniture design are also common abroad.

A variety of architectural and design techniques when using plastics and polymeric materials can be traced by the example of large-sized chairs and armchairs.

For the first time, the most difficult technical and constructive task of creating a solid molded plastic chair on a metal frame was solved by the American designer C. Eames in 1950, who transformed the classic three-part design (seat, backrest, elbows) into an integral bowl shape. In 1955-1957 E. Saarinen, developing this technique, created a stool-glass on one leg-support instead of four. The reception, found by E. Saarinen, is also developing in recent works of Finnish furniture makers using polymeric materials.

Of interest is a series of tables and chairs designed from fiberglass. The series includes nine models of single-support tables, differing in shape, size of the covers.

Fig. 16. The use of artificial leather for the decoration of furniture in cafes and restaurants: a - a set developed by VKTIM

The proportions of the parts, as well as the nature and dimensions of the bases of the support are different, which gives the products a variety.

Single seat chairs are designed as a monolithic shell, combining a single seat and backrest. The chair provides all levels of comfort, which is achieved by a gradation of softness, the presence of elbows and height and backrest tilt.

The Finetra series (Finland, the author of the project was Wainno Haa-Palainen) includes lounge chairs for six options, tables of three options and flower girls. The seats and bases of the seats are made of durable white, red and black fiberglass, soft foam rubber padding, and the fabric is aryulk artificial fur. Chairs have the same basic dimensions (with the exception of the height of the back) and differ in the shape of the back. Interestingly solved support, which, along with the traditional form of the glass has the shape of a wide closed volume, expanding upwards. The volume of the same nature is used in the design of flower.

Along with the classical methods of using polymeric materials in modern practice, a number of others can be noted that follow three main directions: production of large batches, which ensures extremely low prices; use as a facing material of paper, i.e., pressed reinforced cardboard; development of inflatable structures with the ability to self-destruct and re-emerge.

Cheap baukasten systems made of plywood and foam cushions and even cheaper ones made of cardboard are widely represented; seat without foam legs; cylindrical stools-hemp, seats of volumetric shapes, curved and assembled from special cardboard patterns.

Inflatable furniture is becoming more and more widespread, which is easy to move and transport, and also to change in shape.

In the field of stationary furniture design, polymeric materials are used for lining external surfaces (covers, walls, etc.) and for the production of loose elements (boxes, tapes, etc.). For racks in bars and cafeterias, various linings of hard and soft polymeric materials are distributed, the decorative properties of which are used in solving various dividing walls (Fig. 16, b).

Fig. 17. Application of aluminum frames for cabinet doors (set of cabinet furniture IB-1E01, author of the project T. E. Tikhomirova, VKPTIM)

In modern household furniture is increasingly being used metal, which makes possible the emergence of new design and artistic solutions. The molded aluminum profile is applied in a set of cabinet furniture (Fig. 17), which made it possible to create a new design and technological solution for frame doors. Aluminum frames are lightweight, durable, technological and can have different coatings: chrome-plated, anodized, enamel, etc. The decorativeness of the furniture is enhanced by the colored panels made of fibreboard lined with patterned fabric, leatherette or plastic. The design of products allows an unlimited number of finishing options due to the choice of color and pattern of the panels and frames and their combination.

In modern foreign practice, metal is also used to construct household furniture. In fig. 18 shows one of the models of metal furniture made in Sweden. Such furniture is characterized by lightness, beautiful lines, expressiveness of bearing elements.

Fig. 18. A household metal chair (Sweden! With a low back

Entirely from metal or in combination with other materials, various furniture is manufactured for equipment of public buildings of almost all types: office and archival, for schools, libraries, shops, restaurants, hotels (Fig. 19). The widespread use of metal for public furniture is explained by its advantages, of which the following are distinguished: suitability for mass production, strength, durability, non-combustibility, uniformity of quality. For the manufacture of furniture products and their parts used thin sheet steel, metal pipe (rectangular, round, square) of different sections, in some cases, cast parts.

An example of the use of aluminum profiles is furniture for office space (IO-1415, IO-1416, OH-043-05, OH-043-05A), developed in the All-Union Design and Technological Institute of Furniture (author of the projects B. A. Vasiliev) . The leading architectural and constructive element in the composition of the rack is molded aluminum pillars equipped with a through-length longitudinal groove on each of the four sides for fastening brackets to any height using braces, which contributes to obtaining various options from a limited number of elements. In the lid of the table along its perimeter an aluminum lining is applied. The artistic characteristics of the products included in the set are built on the alternation of wide and narrow steps of the rack, on the identification of contrasting comparison of the metal and the front surfaces of the body sections.

Fig. 20. Examples of metal furniture for public buildings: a - a chair on one support; b - stowed chairs

The most widely used metal for frame bearing elements: cabinets, racks, tables, chairs, chairs.

The variety of designs of wood-metal tables can lead to several design techniques that characterize the device supports and their connection to the covers (Fig. 21).

Что бы оставить комментарий войдите

Комментарии (0)