In the manufacture of products from natural materials, a person practically does not interfere in their structure, but only gives them a given shape. These materials include wood and natural stone.

3.1. Forest materials

The quality of wood depends on the type of wood. Tree species are divided into two main groups: coniferous and deciduous. The coniferous species widely used in construction include pine, larch, spruce, fir and cedar. Hardwood in construction is used much less frequently than coniferous. Among the variety of hardwoods, oak, ash, beech, birch, aspen have the greatest use in construction.

Both in structure and in physico-mechanical properties, wood is a natural composite material.

COMPOSITION, STRUCTURE AND CONDITION OF WOOD

Microstructure is the structure of a tree trunk that is visible under a microscope, macrostructure is visible with the naked eye or through a magnifying glass.

By chemical composition, wood is composed of organic substances represented by carbohydrates (about 70% in conifers and 80% in hardwoods). The main carbohydrate component is cellulose (C6H10O5) n, where n is the degree of polymerization, which in wood pulp reaches values from 300 to 6000 and more. About 30% of wood is made up of aromatic substances, known as lignin , also a natural polymer, which is a high molecular weight aromatic part. Extractive substances belong to a small part of wood (2 ... 4%). Unlike carbohydrates and lignin, these are low-molecular compounds, mainly alkaline earth metal salts. Although they are few, they give wood its color, smell, taste, sometimes toxicity, and help the tree resist rotting, fungi, etc.

Long threadlike chain molecules of cellulose form spiral-shaped wood fibers: fibrils and microfibrils — thin fibrils , several layers of which are compactly laid and directed along spirals at different angles to the longitudinal axis of the cell and form the walls (shell) of the cells. Fibrils and microfibrils have a crystalline structure, have high tensile strength, but easily bend. Together, fibrils and microfibrils combine lignin with the help of hydrogen and van der Waals bond and cohesion forces.

Felled wood consists of dead cells - tracheids (for conifers), i.e. only from cell membranes. The main number of cells are spindle-shaped with an average width of 50 μm and a length of 3 mm and stretched along the stem, and some in the horizontal direction (cells of the core rays). Thus, from an engineering point of view, any wood can be considered a bundle of parallel tubes. Since the material of these tubes is essentially the same for all species, the strength of wood depends on the wall thickness and, therefore, on the average density of the wood.

In addition, wood contains capillaries and pores of various sizes; during the life of a tree, they are of great importance for the movement of water and nutrient juices, their accumulation, etc. Large capillaries can be filled with water, which has little effect on the condition of wood and its quality (mechanical properties) as a building material. This moisture comes relatively easily into the capillaries and pores, especially when the tree comes into contact with water, fills the cavities and can be up to 100 ... 200% by weight of absolutely dry wood. It is relatively quickly and easily removed from them during drying. Small pores and capillaries are filled not only upon contact with water , but also in humid air conditions. This causes wood hygroscopicity and moisture deformations.

The macrostructure of wood depends on the cut of the trunk: transverse (face), radial, passing through the axis of the trunk, and tangential, passing along the chord along the trunk. When considering the cuts of a tree trunk, one can distinguish the following main parts of it: the core, the bark, the cambium and the wood itself.

At the mega scale level, a growing tree consists of a root system, a trunk and a crown. The trunk is of industrial importance, since it produces from 60% to 90% of wood.

In addition to the structural elements indicated by us, the structure of wood is also characterized by the presence of defects: knots (violate the homogeneity of the structure of wood, cause curvature of the fibers and impede mechanical processing), cracks (violate the integrity of timber, reduce their mechanical strength and durability), shape defects of the trunk (increase waste sawing and peeling logs, cause the appearance of radial inclination of fibers in lumber and veneer, and, consequently, a decrease in the strength of these materials), chemically color (can spoil the appearance of the coating materials), fungal lesions (dramatically reduces mechanical properties of wood until its complete uselessness) and others.

Decorative wood is due to its texture, color and gloss. The texture is a wood pattern, depending on the combination of its visible elements: annual layers, core rays, vessels. The color and texture of wood are characteristic of each type of wood. Glitter wood depends on the density and degree of processing. Glitter is given to wood by polishing and varnishing. The wood loses its luster when it decays. The smell of wood depends on its content of resinous, essential and tannins.

Structural properties . Low density of wood ensures its low thermal conductivity . The thermal conductivity of dry pine across the fibers is 0.17 W / (m · ° C), along the fibers of 0.34 W / (m · ° C). The wood is hardy and insoluble in water and organic solvents. In addition, such structures have reliable chemical resistance in environments that are aggressive to steel and concrete.

The strength of wood as an anisotropic fiber material depends on the angle at which the force is directed to the fibers. The strength of wood under compression along the fibers is 3 ... 6 times greater than the strength across the fibers, and is about 40 ... 60 MPa. The strength of wood under tension along fibers (60 ... 170 MPa) is on average 2.5 times greater than the corresponding compressive strength. The strength of wood in bending is very high: it is about 1.8 times higher than the compressive strength along the fibers and is about 70% of the tensile strength. Therefore, wood (beams, decking, etc.) most often works on bending.

Although in absolute terms the strength of wood is significantly inferior to high-strength steel and fiberglass, its specific tensile strength along the fibers (the ratio of strength to relative density) is about the same as that of these most durable materials. This leads to its high competitiveness and allows the construction of wooden structures with a span of up to 100 m and more.

Wood has positive technological qualities: ease of technological processing with giving to the products practically any forms; reliable adhesion and good nailability.

However, wood has a number of disadvantages that limit its scope in construction. These include defects in the structure; hygroscopicity and, as a result, moisture deformations - shrinking and swelling, which cause warping and cracking of forest materials; decay and flammability due to the easy oxidation of wood.

Virtually all of these shortcomings are relatively easily overcome by technical means. To protect the wood from rotting, wood drying is used, constructive measures to prevent the structures from wetting during operation, and wood impregnation with antiseptics.

Wood is protected from insect damage by treating the wood with toxic substances - insecticides , which use antiseptics on organic solvents and other substances.

Flame retardants are applied to wooden structures or wood is impregnated with chemical substances - fire retardants . The fire retardant effect of the flame retardants is based on the fact that some of them, when the wood is heated, create a melted film, blocking the access of oxygen to the wood, others at high temperatures emit gases that prevent the wood from burning.

By the method of machining all timber is divided into six classes:

1. Round timber obtained by dividing the whip into sections of standard length from 1 to 6.5 m with a gradation of sizes every 0.25 m. These include: logs intended for use in round form or as a raw material for the production of sawn timber and blanks; ridges (churaki) used to develop special types of timber - peeled and planed veneer, sleepers, etc .; pulp and wood pulp balances .

From lumber produce:

- planed and sheet piling and bars;

- milled products (baseboards and fillets for sealing the corners between the walls and the floor, handrails and frames for covering the door and window frames);

- plank and shield parquet;

3. Shelled timber produced by cutting wood in a spiral (peeling). As a semi-finished product, peeled veneer is used for the manufacture of plywood, wood laminated plastics and veneering (veneering) wood products.

4. Planed timber produced by cutting wood with knives that form a flat section surface. These include planed veneer , which is made of wood with a beautiful texture, color and pattern, and used as a facing material for the production of decorative plywood. Planing is also obtained plaster dran, 4 mm thick, 19 ... 32 mm wide and from 500 to 1500 mm long.

At the same time, coniferous and soft hardwood wastes are mainly used.

5. Chipped timber produced by the longitudinal separation of wood with wedge-shaped tools. By splitting get stabbed balances. After the removal of the heart rot from the low-quality wood, when splitting logs, a full-fledged raw material for the production of cellulose and pulp is formed.

6. Shredded timber obtained by processing wood on special equipment (chopping, planing, grinding). This category of materials includes process chips , process sawdust , shavings and wood flour . They are widely used as aggregates in the production of chipboard and fibreboard, cement particle board, wood concrete, fibrolite, xylolite, construction biocomposites.

3.2. Stone materials and products

Stone materials and products are made of rocks. Rock is a natural mineral aggregate of more or less of a certain composition and structure, which is a product of geological processes and forms independent bodies in the earth's crust.

The properties of rocks, and, accordingly, products made of natural stone, depend on the origin of the rock and its mineralogical composition. Depending on the formation conditions, the rocks are divided into three genetic groups: igneous, sedimentary and metamorphic .

Rocks are composed of minerals. Minerals are natural physically and chemically homogeneous bodies that occur in the earth's crust as a result of physical and chemical processes. About 50 minerals are involved in rock formation. Rocks can consist of both single (monomineralic) and several (polymineral) minerals. All minerals differ from each other in composition, structure, and properties; therefore, the predominance of certain minerals in the rock determines its building properties.

Minerals are usually in a solid state. Most have a crystalline structure, but there are also amorphous ones (for example, opal, tripoli, volcanic glass). By chemical composition, minerals are divided into four main groups: quartz, aluminosilicates, ferrous magnesium, carbonates, and sulfates.

The average density of stones is from 0.5 to 3.3 g / cm3. According to this indicator, natural stones are divided into light (with a density of not more than 1.8 g / cm3) and heavy (more than 1.8 g / cm3).

Light stones have a porous structure and low thermal conductivity (volcanic tuff, pumice stone, shell limestone), and therefore are used in the construction of walls of residential and public buildings in the form of wall stones and blocks and crushed stone for light concrete. The disadvantage is low strength and durability.

Dense stone materials (from granite, syenite, diorite, etc.) are laborious, have a large mass and high thermal conductivity. But they are characterized by high compressive strength (up to 500 MPa), durability (for example, granite up to 1500 years), architectural expressiveness (color, texture and surface texture), high fire resistance (except granite). They are used for facing works, floor installation, for hydraulic engineering and road construction, etc.

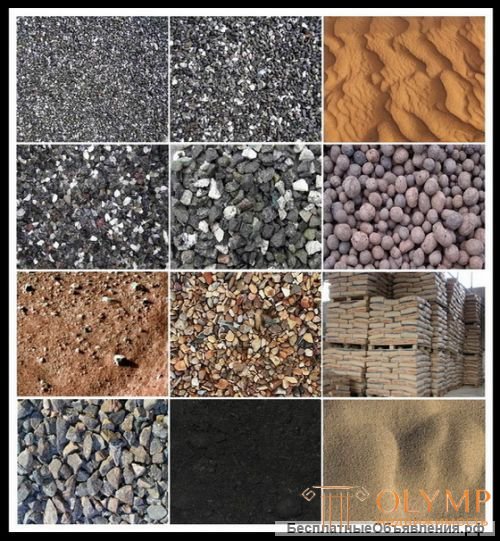

Products from natural stone are divided into the following main types: roughly processed (rubble stone, crushed stone, gravel and sand); stones and blocks of regular shape (for laying walls, etc.); plates (facing for walls, a pure floor, etc.);

profiled parts (steps, window sills, belts, platbands, column capitals, etc.); products for road construction (side stone, paving stone, checker for paving).

Что бы оставить комментарий войдите

Комментарии (0)