Breakdown of earthworks. The breakdown of structures consists in establishing and fixing their position on the ground. The breakdown is carried out with the help of geodetic instruments and various measuring devices.

Breakdowns of pits begin with the removal and consolidation on the ground in accordance with the project of building the main working axes, for which the main axes of the building are usually taken. After that, around the future trench at a distance of 2 ... 3 m from its edge parallel to the main center axes they arrange a runaway.

Single use obnozka consists of metal racks or dug-in wooden poles driven into the ground and wooden planks attached to them. Board not less than 40 mm thick should have a cut edge facing up, and be attached at least three columns strictly horizontally. More advanced is the metal inventory shuffle. For the passage of vehicles in the obnojka arrange breaks. With a significant slope of the area make a runoff ledges.

The main centering axes are transferred to the obnojka and, starting from them, they mark out all the main axes of the building. All axes are fastened to the trim with nails or kerfs and numbered. On a metal cast, the marking of the axes is carried out with paint. The dimensions of the pit on top, and after its passages and on the bottom, as well as other characteristic points, are marked by clearly visible pegs or landmarks. After the construction of the underground part of the building, the main centering axes are transferred to its base.

For linearly extended structures (trenches), only cross-castings are arranged, which are located on straight sections of the route after 50 m, on roundings - after 20 meters. They are also arranged on all pickets and break points of the profile profile.

Water drainage and lowering of the groundwater level. At the device of the notches located below the groundwater level, it is necessary to drain the water-saturated soil and ensure its development in normal conditions. In addition, it is necessary to prevent the ingress of groundwater in the pits, trenches and production and the period of production of work in them.

An effective technological method for solving such problems is the pumping of groundwater. Ditches and trenches with a small inflow of groundwater are developed using open drainage, and if the inflow is significant and the large thickness of water-saturated layer to be developed, then before starting production, the groundwater level is artificially lowered using various methods of closed drainage called water drainage.

Open drainage is used for pumping leaking pods directly from the pits or trenches by pumps. With open drainage, groundwater seeps through the slopes and bottom of the pit and is directed along dug drainage channels or chutes to specially constructed sumps, called sumps , from which water is pumped out with diaphragm or centrifugal pumps of appropriate capacity.

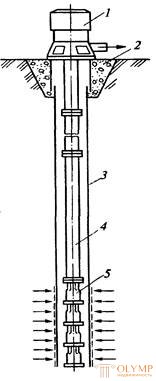

Fig. 2.2. Well-well diagram: 1 - pump drive; 2-sprinkling; 3 - filter column; 4 - water pipe; 5 - pump | Pumps are selected depending on the flow rate (inflow) of water, and the flow rate is calculated according to the formulas of steady-state groundwater movement. The drainage ditches are arranged with a width along the bottom of 0.3 ... 0.6 m and a depth of 1 ... 2 m with a slope of 0.01 ... 0.02 m in the direction of the pit. Themselves priam Open drainage is a simple and affordable way of dealing with groundwater, but it has a serious technological drawback. Ascending streams of groundwater flowing through the walls and bottom of pits and trenches, liquefy the soil and transport small particles from it to the surface. As a result of this leaching, this method has several significant drawbacks: ■ decreases the natural strength of the base of the excavation due to washing it with running water; ■ the presence of water at the bottom of the excavation makes it difficult to excavate; ■ it is necessary to fix the walls of the grooves, since the movement of water to the sump leads to movement and soils; ■ The flow of water to the catchment can cause weakening of the bases of buildings and structures located near the object under construction. In cases where the drainage is impractical, three change the artificial lowering of the groundwater level (water decrease). |

Water lowering reduces the level of groundwater (GWL) below the bottom of the future excavation. The lowering of the groundwater level consists in pumping groundwater by submersible pumps from mine wells (Fig. 2.2) or drilling water-lowering wells located in close proximity to the future trench or trench. At the same time, GWL decreases sharply, the soil previously saturated with water and now dehydrated, is being developed as a soil of natural humidity. When water is lowered, it is possible to maintain the integrity of the slopes of the grooves and prevent the removal of soil particles from under the foundations of nearby buildings.

Several other effective methods have been developed for artificial water lowering, the most important of which are needle filter, vacuum and electroosmotic.

The needle filtering method of artificially lowering the groundwater table is based on the use of needle filter units consisting of steel pipes with a filter element in the lower part (needle filter), a catchment collector on the ground surface and a self-priming vortex pump with an electric motor. Steel pipes are immersed in flooded soil around the perimeter of the pit or along the trench.

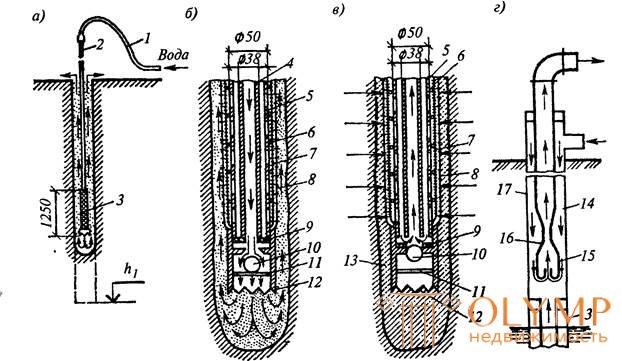

The needle filter consists of two parts: the filtering link and the superfilter pipe (needle filter diameter 40 ... 50 mm). The filter link, in turn, consists of an internal deaf and external perforated pipes. This pipe is wrapped with wire from the outside, reinforced with filtration and protective nets; the bottom of the pipe ends with a milling tip, inside of which are placed ball and ring valves (Fig. 2.3.-2.5).

Fig. 2.3. Scheme of operation of the needle filter installation:

a - general view; b - the period of immersion of the needle-link in the ground; in - the period of water decrease; g - ejector needle filter; 1 - flexible hose; 2 - above filter pipe; 3 - needlepoint link; 4 - inner tube; 5 - outer perforated tube; 6 - spiral winding; 7-filtration mesh; 8 - steel safety net, 9-ring valve; 10 - ball valve; 11 - limiter; 12 - a gear tip; 13 - sand and gravel mixture; 14 - the outer tube of the ejector; 15 - ejector nozzle; 16 - narrowed pipe section; 17 - vacuum zone

For lowering the needle filter to the working position in difficult soils, drilling of wells is used in which the needle filters are lowered (at depths of up to 6 ... 9 m). In sands and sandy soil, the needle filters are immersed hydraulically (Fig. 2.3, b), by washing the soil under the milling tip with water with a pressure of up to 0.3 MPa. Acting in the upper part of the tip, the water lowers the ball

the valve comes under pressure to the bottom of the nozzle, eroding the surrounding soil, including along the perimeter of the pipe. Under the action of its own weight, the needle filter is immersed in the ground, the annular valve closes the space between the outer and inner tubes during the process of immersing the pipe. After immersion of the needle filter to the working depth, the hollow space around the pipe is partially filled with sagging soil, partially covered with coarse sand or gravel.

the valve comes under pressure to the bottom of the nozzle, eroding the surrounding soil, including along the perimeter of the pipe. Under the action of its own weight, the needle filter is immersed in the ground, the annular valve closes the space between the outer and inner tubes during the process of immersing the pipe. After immersion of the needle filter to the working depth, the hollow space around the pipe is partially filled with sagging soil, partially covered with coarse sand or gravel.

When the entire system is turned on to the water pumping mode (Fig. 2.3, c), the needle valves ball valves due to creep and under the influence of vacuum rise up and close the opening, while the annular valve is lowered, opening the way for ground water through the grid cells to the space between the pipes and further inner tube.

The needle filters allow for a single-tier arrangement to lower the groundwater level by 4 ... 5 m, and for a two-tier one, by 7 ... 9 m. The needle filters are located 0.5 m from the edge of the pit or trench. Narrow trenches with a depth of 4.5 m and a width of up to 4 m are drained with one row of needle filters, and with a greater width and depth, with two rows.

The distance in the row between the needle filters is prescribed depending on the properties of the soil and the depth of the lowering of the groundwater level. For medium grained soils with

Fig. 2.4. Water lowering by the needle filter: a - installation diagram; 6 - needle filter during hydraulic washing; in - the same, when pumping water; 1- inner tube; 2-outer tube; 3 - filter mesh; 4 - ring valve; 5 - saddle; 6 ball valve; 7 - limiter; 8 - tip | a filtration coefficient of 2 ... 60 m / day takes a distance in the range of 1 ... 1.5 m; in strongly filtering large sandy and sandy-gravelly soils, the distance is reduced to 0.75 m. The needle filter installation consists of a series of needle filters that are immersed in the soil along the perimeter of the future excavation, on one or two sides of the trench. On the surface of the earth, the needle filters are connected by a drainage collector to the pumping unit. When the pumps operate in the water pumping mode, due to the drainage properties of the soil, the water level in the needle filter and the surrounding soil layers decreases, which leads to the formation of a new groundwater table, which is called a depression curve. The vacuum method of water lowering is based on the use of ejector water power plants. These plants are used to lower the level of groundwater in fine-grained soils (fine-grained and silty sands, sandy loam, silty and loess soils with a filtration coefficient of 0.02 ... 1 m / day), in which it is impractical to use light-needle filters. During the operation of vacuum water-vacuum installations, a vacuum arises in the zone of an ejector needle filter (Fig. 2.3, d). Ejector installation is applicable for lowering the groundwater level by one |

tier to a depth of 15 ... 20 m; The optimal conditions for the operation of the ejector are 8 ... 18 m. The filter element of the ejector is decided on the principle of a light needle filter, and the over-filter element consists of external and internal pipes with an ejector nozzle. The immersion into the soil of the column of the above-filter pipes is carried out, as in the case of the needle filter, by a hydraulic method, the soil is eroded, the pipe is lowered under the action of gravity. When the column is lowered to the required level, the inner tube with the ejector is lowered inside.

During the working period, working water from the surface under pressure of 0.75 ... 0.8 MPa is supplied to the nozzle of the ejector in the annular space between the inner and outer tubes. Coming out of the ejector nozzle, a jet of this water creates a vacuum in the surrounding annular space and draws water from the main working tube. As a result of an abrupt change in the speed of movement of the working water, a vacuum is created in the nozzle and thus the groundwater is sucked in. Groundwater, mixing with the working, flows through the pipe upward under the action of the suction pump into the circulation tank. The water pumped out of the ground is discharged from the catchment tank by means of a gravity pipe outside the pit or construction site.

During the working period, working water from the surface under pressure of 0.75 ... 0.8 MPa is supplied to the nozzle of the ejector in the annular space between the inner and outer tubes. Coming out of the ejector nozzle, a jet of this water creates a vacuum in the surrounding annular space and draws water from the main working tube. As a result of an abrupt change in the speed of movement of the working water, a vacuum is created in the nozzle and thus the groundwater is sucked in. Groundwater, mixing with the working, flows through the pipe upward under the action of the suction pump into the circulation tank. The water pumped out of the ground is discharged from the catchment tank by means of a gravity pipe outside the pit or construction site.

The phenomenon of electroosmosis is used to expand the field of application of needle filter systems in soils with a filtration coefficient of less than 0.05 m / day. In this case, along with the needle filters, at a distance of 0.5 ... 1 m from the needle filters on the side of the excavation, steel pipes or rods are immersed to a depth identical to the needle filters immersion. The needle filters are connected to the negative (cathode), and the pipes or rods - to the positive pole of the DC source (anode) (Fig. 2.5. B).

|

|

GWL |

GWL |

Electrodes are placed relative to each other in a checkerboard pattern. The pitch or distance of the anodes and cathodes in their row is assumed to be the same within 0.75 ... 1.5 m. Welding machines or mobile current transducers are used as a power source. The power of the DC generator is determined from the required current strength 0.5 ... 1 A per 1 m2 of the area of the electroosmotic curtain at a voltage of 30 ... 60 V. Under the action of an electric current, the water contained in the pores of the soil is released and moved along towards

Fig. 2.5. Schemes of needle filters with vacuum (a) and electroosmotic

(b) water lowering:

1 - vacuum pump; 2 - depression curve after lowering the water level with an acupuncture filter; 3-filtering link; 4 - centrifugal pump; 5 - steel pipe (anode); 6-filter (cathode); 7 - depression curve after electrodrying

due to electroosmosis, the filtration coefficient of the soil increases by 5 ... 25 times.

The application of each of the methods described for lowering the groundwater level depends on the thickness of the aquifer, the filtration coefficient of the soil, the parameters of the earthworks and the construction site. The decision on the choice of method should also be justified from the standpoint of environmental protection and environmental safety of the constructed object.

The use of installations for artificial water lowering causes the need to solve environmental problems. First of all, it is the need to use environmentally friendly technologies that would not allow contamination of groundwater and the ingress of harmful impurities into them.

Often with intensive pumping of groundwater in the area of construction, hydrogeological conditions are disturbed, the relationship of groundwater with surface water, resulting in violations of existing water intake systems, drainage of springs, etc. Long-term pumping of groundwater is particularly dangerous in built-up urban areas, since they can cause subsidence of the earth's surface, deformation of buildings and structures, the displacement of the axes of engineering networks. Therefore, the choice of ways to protect earthworks from the effects of groundwater should be accompanied by the analysis and development of appropriate environmental measures.

Creation of artificial anti-filtration curtains and screens. For fencing pits, trenches, underground workings and protection of construction work carried out in them from groundwater inflow depending on the physical and mechanical properties of the soil, its condition, and the thickness of aquifers, there are the following methods of soil consolidation: freezing, injection of hardeners into the soil , the creation of thixotropic anti-filtration screens and curtains, the device of sheet piling.

In highly water-saturated soils (quicksand), when developing deep dredging, underground structures, impervious curtains are created using natural or artificial freezing of soils.

For lowering the needle filter to the working position in difficult soils, drilling of wells is used in which the needle filters are lowered (at depths of up to 6 ... 9 m). In sands and sandy soil, the needle filters are immersed hydraulically (Fig. 2.3, b), by washing the soil under the milling tip with water with a pressure of up to 0.3 MPa. Acting in the upper part of the tip, the water lowers the ball

List of used sources

1.SNiP 3.02.01-87 Earthworks, foundations and foundations

2.SNiP 3.01.01-85 (as amended. 1 1987, 2 1995) Organization of the construction industry

Что бы оставить комментарий войдите

Комментарии (0)