Loosening of frozen soil with the subsequent development of earth-moving and earth-moving machinery is carried out by mechanical or explosive method.

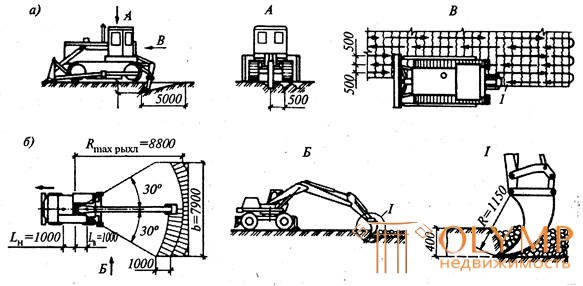

Mechanical loosening of frozen ground using modern high-capacity construction machines is becoming more common. In accordance with the requirements of ecology, before the winter development of the soil, it is necessary to remove the layer of vegetative soil from the site planned for development in the autumn period by bulldozer. Mechanical loosening is based on cutting, splitting or chipping of frozen soil with static (Fig.3.3.) Or dynamic impact.

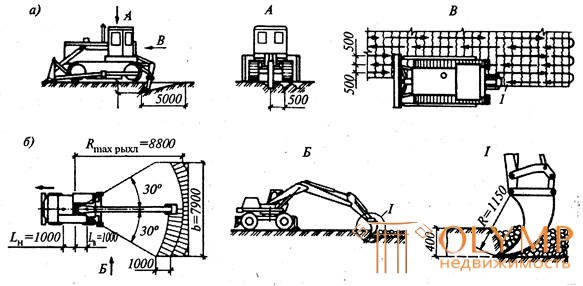

When a dynamic impact on the ground is its splitting or chipping with free-fall hammers and directional action (Fig.3.4.). In this way, the loosening of the soil is produced by free-fall hammers (ball-and wedge-hammers) suspended on the ropes on the arrows of excavators, or directional hammers, when loosening is carried out by chipping the soil. Loosening by mechanical means allows its development by earth-moving and earth-moving machinery. Hammers weighing up to 5 tons are dropped from a height of 5 ... 8 m: a hammer in the shape of a ball is recommended to be used when loosening sandy and sandy sandy soils, wedge-hammers - for clayey (with a frost depth of 0.5 ... 0.7 m). As a directed hammer, diesel hammers on excavators or tractors are widely used; they allow destroying frozen ground to a depth of 1.3 m (Fig. 3.5.).

The static impact is based on the continuous cutting force in the frozen ground of a special working body - a ripper tooth, which can be the working equipment of a hydraulic “backhoe” excavator or be mounted equipment on powerful tractors.

Fig. 3.3. Loosening of frozen soil with static effects: a - with a bulldozer with active teeth; b - excavator ripper; 1 - the direction of loosening

| Fig.3.4. Loosening of frozen ground by dynamic impact: a - scheme of loosening free fall with a hammer; b - the same, diesel-hammer; in - the same vibrohammer; g - the same, with a depth of freezing up to 1.5 m; d - the same, with a depth of freezing more than 1.5 m; 1 - hammer; 2 excavator; 3 - frozen soil layer; 4 - guide rod; 5 - diesel hammer; 6-vibromolot |

Loosening with static rippers on the basis of the tractor implies, as an attachment, a special knife (tooth), the cutting force of which is created by the tractor's tractive effort. Machines of this type are designed for layer-by-layer loosening of the soil to a depth of 0.3 ... 0.4 m. The number of teeth depends on the tractor power, with a minimum tractor power of 250 hp one tooth is used. Soil loosening is carried out in parallel layer-by-layer penetrations through 0.5 m with subsequent transverse penetrations at an angle of 60 ... 90 ° to the previous ones. Moving the loosened soil to the dump carry bulldozers. It is advisable to attach the attachment directly to the bulldozer and use it to independently move the loosened soil. The capacity of the ripper is 15 ... 20 m3 / h.

The ability of static rippers in layers to develop frozen soil makes it possible to use them regardless of the depth of soil freezing. Modern rippers based on tractors with dozer equipment, due to their wide technological capabilities, are widely used in construction. This is due to their high efficiency. So, the cost of developing the soil with the use of rippers compared to the explosive method of loosening is 2 ... 3 times lower. The depth of loosening of these machines is 700 ... 1400 mm.

Fig. 3.5. The scheme of the joint work of the diesel hammer and excavator "straight shovel" | Loosening of frozen soils by explosion is effective with significant amounts of frozen soil development. The method is used mainly in undeveloped areas, and those with limited construction, using shelters and explosion locators (heavy load plates). Depending on the depth of soil freezing, explosive works are performed: ■ by the method of pre-charge and slot-hole charges with a depth of soil freezing up to 2 m; ■ method of borehole and slot charges at a depth of freezing above 2 m. |

Boreholes are drilled with a diameter of 22 ... 50 mm, wells - 900 ... 1100 mm, the distance between rows is taken from 1 to 1.5 m. The slits at a distance of 0.9 ... 1.2 m are cut one by one by cutting machines. milling type or bar machines. Of the three adjacent slits, the explosive is placed only in the middle one; the extreme and intermediate slits serve to compensate for the shift of the frozen ground during the explosion and to reduce the seismic effect. Charge the cracks with elongated or concentrated charges, after which they are filled with melted sand from above. With the quality of the preparatory work in the blasting process, the frozen ground is completely crushed without damaging the walls of the excavation or trench.

The soil loosened by explosions is developed by excavators or earth-moving machines.

Что бы оставить комментарий войдите

Комментарии (0)