The era of metal water pipes has long been over. Such material as polypropylene, as well as the technology of welding of polypropylene pipes are nowadays at the head of the corner, with regard to water supply systems, heating, etc. in a house or apartment.

At the turn of the century, the inhabitants of the old high-rise buildings began to replace metal pipes for plastic, which in those days were still far from perfect and now require another replacement. Statistics show that today over 70% of pipelines are made of polypropylene.

At its cost, polypropylene pipes are cheaper than metal ones, while the lifetime of such pipes is much higher, and the number of required efforts to install them is incomparably smaller. Among other things, the mass of polypropylene is the lowest among all polymers, and even polyethylene.

This fact, respectively, affects the reduction of the cost of transportation of the material, in addition, the compactness of the material can be achieved by investing pipes of smaller diameter in products with larger ones.

If you want to change the riser or make installation of plumbing from polypropylene pipes in your apartment, you do not need to rush to call the master - all the work can be done independently, of course, if you have the desire and free time.

To date, the technology has been developed for the installation of polypropylene pipes, which includes the assembly of pipes of various diameters, as well as all the necessary connecting elements, contours, inclusions, fixing and shut-off valves.

The complete set of the system is designed in such a way that it allows to construct a pipeline scheme of any configuration and complexity. The only minus of pipelines made of polypropylene, and the indirect one, is the impossibility of a connector with a welded connection method.

Therefore, the technology of connecting polypropylene pipes rebuses the utmost composure to prevent mistakes in the assembly.

Everyone can master the method of welding polypropylene pipes with his own hands, however, the beginner in this case is waiting for a lot of possible mistakes, mainly due to carelessness or haste. Before welding pipe elements, it is necessary to verify several times that their calculations and dimensions are correct.

Now regarding soldering - the method of connecting polypropylene pipes with fittings and structural details. The tool with which to carry out welding, the people called the soldering iron. And although from the point of view of technology, this name is incorrect, such a simple and understandable term has taken root and has become applicable even in the circle of professionals.

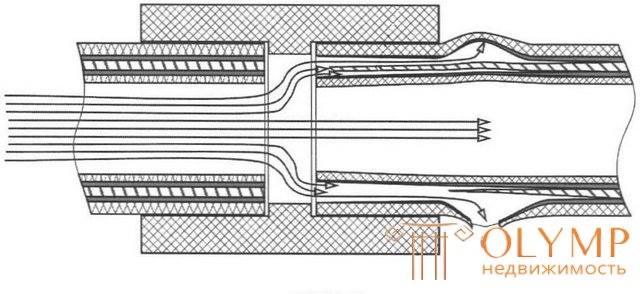

The process of welding pipes made of polypropylene is as follows:

Such a welded joint has such tightness and strength that it can withstand almost any pressure.

Cleaning polypropylene pipes is not at all cleansing it from dirt or polishing rough edges. And what exactly - we will tell in this chapter. To begin with, let's say that pipes made of polypropylene have not only many unique advantages, but also some features that cannot be ignored. The most important of them is, first of all, the working temperature, which can not be more than + 95 ° C in accordance with state standards , however, as experts note, in some unforeseen circumstances, it still passes this threshold. We note here that in the winter, such cases occur regularly , and in the northern regions - constantly, because in order to get the declared +95 at the exit, at the entrance it is necessary to warm the water up to +110, and in some cases up to +120 .. . + 130 ° C, which causes high linear thermal expansion of any polymer pipes, if additional protection is not provided - reinforcement .

We also add that when the water temperature rises to such extreme values, it is necessary to significantly increase the supply pressure - otherwise the water would simply turn into steam. The properties of even ordinary high-quality polypropylene help to maximize thermal expansion, but in cases where polypropylene is laid under the plaster or screed, even minor changes lead to undesirable consequences. The panacea for these evils was reinforcement. Such a pipe practically does not expand when heated, and when softened, the reinforcement keeps it from deformation. However, one should not overestimate the importance of reinforcement in pipes: it improves the characteristics of the pipe itself, but for the system as a whole does not solve all the problems. The fact is that if the temperature of the liquid significantly exceeds the mark of 100 degrees, then the system may not withstand the increased pressure at the joints of the pipes with the fittings - therefore you need to carefully prepare the reinforced pipes for installation in heating systems (and even hot water) ), that is, to clean them up. However, not every reinforced pipe needs to be stripped - only those that are reinforced with aluminum foil. For this, a few words about the types of reinforcement of polypropylene.

To date, several types of reinforcement pipes are used, the main of which are three : reinforcement with aluminum foil, reinforcement with fiberglass (or fiber fibers), and also reinforcement with basalt fiber.

And finally, we come to such an important procedure as stripping of reinforced polypropylene pipes. Stripping is used when using only pipes with aluminum reinforcement before welding it with a fitting to remove the foil from the joining point. And since only pipes with aluminum reinforcement are suitable for heating, there is simply no alternative but to use pre-sanded polypropylene pipes.

The connection of the fitting to the pipe implies that the outer layer of the pipe and the inner layer of the fitting will melt , and during cooling they form a uniform seam. In the case when the reinforcement is done on the outer surface of the pipe, welding will simply not occur . When reinforced along the inner radius, the aluminum that is not removed from the junction will not affect the quality of welding, but will be in contact with water in further operation, which will inevitably lead to corrosion of the metal sheet and, as a result, to the separation of the pipe. If the pipe is reinforced with fiberglass or basalt fiber, then the above manipulations are not needed . The fiberglass and basalt mesh does not affect the connection, and does not deteriorate when interacting with water, however, as we have already said, such pipes cannot be installed on the heating.

And now the most important thing . Some European, as well as most of the Chinese, Turkish and partly Russian manufacturers declare that they produce so-called "clean-up" pipes, which, prior to installation, supposedly do not need to be cleaned. Let's figure it out. As we have already found out, aluminum reinforcement can be located closer to the outer edge of the pipe, and can also be located in the center. Pipes with external aluminum reinforcement are manufactured by most European manufacturers, which have been producing polypropylene pipes for quite a long time , as well as new companies that want to prove themselves from the best side. The fact is that the layer of reinforcement, which is located close to the outer edge of the pipe, gives it a very tangible strength . It turns out that the inner layer of polypropylene is covered by a layer of reinforcement, and does not expand under the influence of elevated temperatures. The outer thin layer of polypropylene in this case plays only an auxiliary role, protecting aluminum from contact with the external environment, that is, the reinforcement layer is reliably protected from corrosion.

And now the story will be about pipes with aluminum reinforcement, in which a layer of aluminum foil is located in the center of the pipe . Manufacturers of such pipes declare that they, as it were, do not need to be stripped. In fact, it is not . At first glance, when welding pipes with aluminum reinforcement in the center, the reinforcing layer will not contact the welding point. However, this is only partly true. The fact is that without removing aluminum from both ends to a certain depth, the weld will not be too strong, and the aluminum will sooner or later begin to contact with water, which at different potentials inside the heating circuit or the GSV / XSV system will lead to electrochemical corrosion, which over time, it will simply destroy the aluminum foil layer. Because of this, the pipes are threatened not only by separation, but also the strength suffers significantly, and also the heat resistance decreases .

And in the systems of cold drinking water supply, corrosion processes noticeably deteriorate the quality of the environment, because in this case corrosion products will start to get into the water. That is, as we have seen, the stripping of “clean-clean” pipes is also required without fail . However, marketers have gone even further and declare that the pipes with aluminum reinforcement in the center, which they produce, do not require stripping , and they only need trimming. However, trimming, as we will see below, is, in fact, exactly the same sweep, but this is about the inner layer of reinforcement. Another question is that we need slightly different tools for trimming than for stripping the outer reinforcing layer of polypropylene pipes, which we will now discuss.

Pipes with reinforcement closer to the outer edge are cleaned in a standard way using special steel couplings, where knives of a special construction are located. To remove aluminum foil from the welding area, you need to put the sleeve on the pipe and turn it. At the same time, there are double-sided couplings, which allow cleaning different pipes, which significantly saves time. At installation of pipeline systems of insignificant length, it is more economical to carry out cleaning manually, otherwise it is more advantageous to use a drill on which couplings are put on. In general, the tool for stripping is divided into two classes : hand-held (couplings and facing tools) and nozzles for power tools.

The principle in both cases is the same - rotating, the nozzle removes the top layer of the pipe, saving the pipe from reinforcement. But you will have to turn the tame ones yourself, and the nozzles on the drill or perforator eliminate this. It is also worth noting that when using nozzles for a drill, it is more difficult to control the stripping process, and polypropylene pipes are quite soft. If you do not plan to clean large volumes of pipes daily, then we recommend using hand tools . All the tools that you need to lay a home pipeline, comes down to the following things: a tape measure, a marker, a welding machine (soldering iron) for connecting pipes and fittings, as well as scissors for cutting pipes or angle grinders and a hacksaw.

Thus, we found that the hand tool for removing the outer layer is a simple coupling with knives on the inner surface, which often make double-sided for working with different pipe diameters. To remove the middle (or, as they often say, the inner) layer of aluminum foil, use facers . Structurally, this is the same clutch, only knives are located on the inner end. The pipes are cleaned in the same way in the other case: we insert the pipe into the internal cavity of the device and make several turns. Nozzles for a drill are similarly adapted to remove the outer and inner layers. The differences in the design between them and the hand tool consist only in the fact that the nozzles have a rod for clamping the drill chuck or for installing it in the drill in place of the drill.

The welding machine for a polypropylene pipe, naturally, includes a welding machine, which is very simple in its design and slightly differs from the construction of a conventional iron, perhaps with its design .

The device also consists of a temperature controller, a heating plate and a handle. The heating plate has two holes that allow the fastening of welded elements in it.

Since during welding of pipes made of polypropylene, the pipe itself and any structural part (fitting) into which the pipe is inserted are usually used, the pair of welding elements (nozzles) of the apparatus is also different in appearance.

The most popular pipes that are used in domestic heating and plumbing systems are products with an external diameter of 32 and 20 mm. Marking on the diameter is available on each polypropylene product.

The standard kit for welding polypropylene pipes includes, as a rule, four pairs of welded elements that allow you to solve almost any task - from 20 to 40 mm in diameter.

They are coated with Teflon coating, which makes independent production of this device impossible. And even if you manage to turn the elements on a lathe, which is not difficult, when heated without Teflon coating, the plastic will stick to the metal.

Before starting the process, wipe the end of the pipe and the inner surface of the fitting element with alcohol. It also contributes to the removal of fine abrasive and dust particles from the surface, which adversely affect the integrity of the Teflon coating of the welding machine nozzles.

Before direct installation, the surfaces of the nozzles also require inspection and processing with alcohol to prevent sticking of the molten plastics, which can be damaged during subsequent mechanical removal.

A fitting of various caliber assume the different depth of a welded connection. This means that before welding the pipes it is necessary to measure the depth with a caliper or a ruler.

In this case, there will be no mistake with the introduction of the pipe into the hole of the element to be connected deeper than it should be. Otherwise, the cross section of the bore hole can be narrowed or the pipe can be sealed completely.

Tip! If you want to learn how to properly solder plastic pipes - video on the Internet, or the instruction attached to the welding machine can help you.

To facilitate the task, a special device is often made, which allows not only to facilitate the measurement process, but also to save time. Such a device for a pipe 20 mm in diameter is made from a pipe segment 32 mm in diameter.

With a planting depth of 20 mm tube in 15mm, it is necessary to cut off a ring of 15 mm in width from a 32 mm tube. Кольцо может быть применено для точной отметки линии, означающей глубину посадки, что весьма удобно при надобности сварки большого числа элементов между собой.

Разметочное кольцо может быть модернизировано приклейкой пластикового или картонного дна, что сведет сложность процесса разметки до минимума. Подобные кольца могут быть изготовлены для полипропиленовых труб всех диаметров, кроме наибольшей.

Обычно пайка полипропиленовых труб своими руками производится одним человеком на столе или полу. Но порой при сборке трубопровода возникает необходимость сварки труб на месте установки. Тогда без еще одной пары рук просто не обойтись.

Помощник при этом должен быть ознакомлен с тем, как правильно сваривать полипропиленовые трубы.

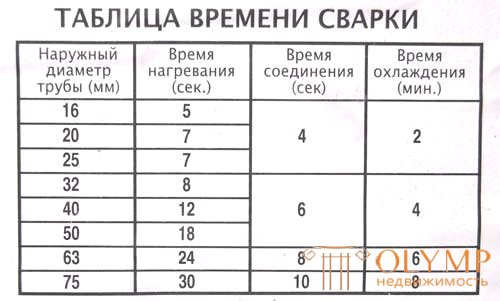

В процессе сварки труб из полипропилена ни в коем случае нельзя медлить. Нужно строго соблюдать время нагрева соединяемых элементов, которое указано в соответствующей таблице для каждого диаметра, в особенности, когда сварка производится на месте установки, и не представится возможности проверки качества соединения .

Наиболее распространенной оплошностью является перегрев деталей, вследствие чего происходит сужение сечения трубы.

Tip! При сварке труб по месту дислокации, одному человеку следует держать сварочный аппарат, а другому стыковать трубу и фитинг сперва с горячими сварными насадками, а после между собой. В одиночку не всегда выходит снять с паяльника одновременно и трубу, и фитинг. Что-то одно может остаться, и тогда помощнику следует незамедлительно помочь с извлечением.

при этом если холодное помещение то время нужно немного увеличить.

глубина погружение зависит от диаметра (лоя этого используют спец. насаднки)

. если будет уменьнено время нагрева, то возможно некачественное соединеникло которое в будущем может дать течь

если будет время больше чеем указано в инсрукции к паяльнику, то возможно оплавление и сужение внутреннего диаметра чтот черевато уменьшению напора в системе.

при использовании длинных цчастков ттрубы на системах с гор. водой или отоплениях неробходимо усанавливать копенсационные трубы (изогнутые трубы).

запрещается уставновка труб горячего или теплоснабженния в цементной стяжке без утеплителя

So, the article on the topic “polypropylene pipes: how to install and how to weld” is over. Now with self-installation of the pipeline you should have no problems.

Any heating system of water type assumes the presence of circuits along which the coolant circulates. These pipe lines connect the boiler with all the heat exchange devices, which are radiators to the most remote ones. As a result, in a building or even a large-area apartment, the overall system can take a very complex branched form, and the length of the laid pipes can be tens or even hundreds of meters.

Polypropylene pipes reinforced with fiberglass for heating

Not so long ago, there was practically no alternative to steel pipes of VGP. But, you see, their purchase, transportation, and installation itself are very complicated, not cheap and not all accessible for independent execution of the event. And, frankly, there are quite a few other flaws in such pipes. Another thing - inexpensive, lightweight, easy to install, and just looks pretty polypropylene pipes. However, not all their varieties are suitable for such purposes, due to the nature of the material of manufacture. But polypropylene pipes reinforced with fiberglass for heating will be an excellent option.

In addition to them, polypropylene pipes are also produced with aluminum reinforcement, therefore, in order to figure out which of them is better, it is worth making a comparison. Only in this way it will be possible to assess and identify the characteristic features of different types of these products.

The heating system will be reliable in operation, if it selects the "right" pipes that meet certain requirements. Such criteria include the resistance of products to high temperature and pressure loads. to aggressive influence of the heat carrier circulating on them. It is especially important to consider these requirements if the pipes and their connecting elements are planned to be installed in a system connected to the central heat supply.

In specialized stores you can find reinforced polypropylene pipes with different wall thickness, made of different quality materials, differing in resistance to high pressure and temperature, UV exposure, and having a different coefficient of linear expansion. Therefore, if it is decided to install a new circuit or replace the old pipes with polypropylene pipes, it is necessary to know the evaluation criteria with which the materials used for these purposes must comply.

So, for the installation of the heating circuit it is necessary to choose pipes that meet a number of important requirements.

Let's say the installation of the heating circuit was carried out at a temperature of +20 ºС. After the start of the heating system, the temperature in the supply pipe is planned to be even just 75 ºС. So, we have a differential with an amplitude of + 55 degrees. With the above thermal expansion coefficient, each meter of our circuit will increase in length by 8.25 mm. Even on a relatively small straight section of 3 meters, this will give 2.5 cm of elongation, not to mention longer sections. But this is already very serious!

Several illustrative examples of what the “penny savings” leads to are the use of unreinforced pipes for the heating circuit.

As a result, the pipes located openly deform, bend, jump out of their clip-on attachments. Naturally, at the same time internal stresses in their walls grow, connecting nodes are overloaded, tightness of threaded connections on fittings can be broken. The system clearly loses not only the aesthetics of its kind, but also the overall reliability.

And what happens to such pipes if they are rigidly embedded in the walls or the floor? It is even difficult to imagine how large internal stresses their walls experience. It is clear that about any durability of such a heating circuit - not even talking.

But for reinforced pipes, the linear expansion coefficient is almost five times less. With the same initial data, the three-meter section is lengthened by only 4.95 mm, which is no longer critical. Of course, this does not obviate the need to compensate for linear expansion on very long sections, but on the other hand, compensators (loop or bellows) will need much less, and they can be placed in inaccessible places.

Compensators for polypropylene pipes loopback (left) and bellows type

Without exception, all polypropylene pipes must have alphanumeric markings on their surface, which indicate their main physico-technical and operational characteristics. When purchasing pipes, it is recommended to carefully study the marking in order not to be mistaken with the choice of the optimal variant.

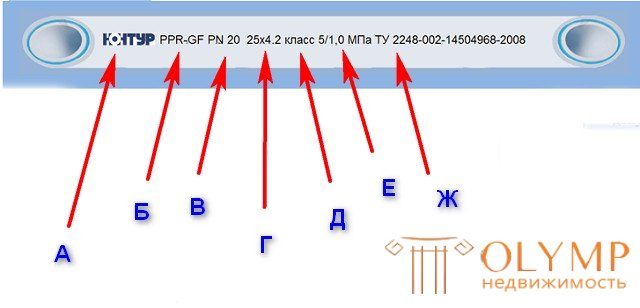

For clarity, consider the labeling by example:

Example of marking fiberglass reinforced polypropylene pipe

And - as a rule, the marking inscription begins with the logo or the name of the company of the manufacturer of the material. In any case, those firms that really enjoy prestige in this sphere of production, do not hesitate to put their name on every unit of their products. Well, if the manufacturer “was modest,” and there was nothing indicated in the labeling - this should be a reason to think whether it is worth buying such a product, whether it is a cheap imitation.

B - The following abbreviation denotes the structural structure of the pipe. Here usually there are such variants of designations:

- PPR - polypropylene pipe, which has no internal reinforcement;

- PPR-FB-PPR - glass fiber reinforced pipe;

- PPR / PPR-GF / PPR or PPR-GF - pipe reinforced with composite material, which includes fiberglass and polypropylene;

- PPR-AL-PPR - pipe, reinforced with aluminum foil.

- PP-RCT-AL-PPR - this complex abbreviation means that the pipe consists of several layers made of different materials. So PP-RCT - the inner one is a modified polypropylene with improved thermostatic properties, AL - the middle layer is aluminum foil, and PPR - the outer layer is polypropylene.

B - The following designation, PN, is a type of pipe, which speaks in large part of its operational characteristics and areas of possible use. Numbers indicate the nominal operating pressure in the system (in bars or technical atmospheres):

- PN-10 - such pipes can withstand a pressure of 10 bar, and can be used for cold water supply or, as an exception, for mounting the supply pipe to the contours of a heated floor with maintaining the appropriate temperature, since they are designed for temperatures not exceeding + 45 degrees.

- PN-16 - products are designed for cold and hot water with a temperature of up to + 60 degrees and a working pressure of up to 16 bar.

- PN-20 is the most demanded option, since it can be called universal, as it is used for both hot and cold water supply, as well as for the circuits of heating systems. Pipes with this marking can withstand a temperature of 95 degrees, and pressures up to 20 bar.

- PN-25 - such pipes are the most durable, withstand a pressure of 25 bar and a temperature of 95 degrees. They are used for installation in risers of heating and hot water systems, including for circuits connected to central heating.

The main standard dimensional parameters of pipes for this classification are presented in the table below:

| Ø Nr, mm | PN -25 | PN -20 | PN -16 | PN -10 | ||||

|---|---|---|---|---|---|---|---|---|

| Ø Вн, mm | TS, mm | Ø Вн, mm | TS, mm | Ø Вн, mm | TS, mm | Ø Вн, mm | TS, mm | |

| sixteen | - | - | 10.6 | 2.7 | 11.6 | 2.2 | - | - |

| 20 | 13.2 | 3.4 | 13.2 | 3.4 | 14.4 | 2.8 | 16.2 | 1.9 |

| 25 | 16.6 | 4.2 | 16.6 | 4.2 | 18 | 3.5 | 20.4 | 2.3 |

| 32 | 21.2 | 3 | 21.2 | 5.4 | 23 | 4.4 | 26 | 3 |

| 40 | 26.6 | 3.7 | 26.6 | 6.7 | 28.8 | 5.5 | 32.6 | 3.7 |

| 50 | 33.2 | 4.6 | 33.2 | 8.4 | 36.2 | 6.9 | 40.8 | 4.6 |

| 63 | 42 | 5.8 | 42 | 10.5 | 45.6 | 8.4 | 51.4 | 5.8 |

| 75 | 50 | 6.9 | 50 | 12.5 | 54.2 | 10.3 | 61.2 | 6.9 |

| 90 | - | - | 60 | 15 | 65 | 12.3 | 73.6 | 8.2 |

| 110 | - | - | 73.2 | 18.4 | 79.6 | 15.1 | 90 | ten |

| Ø Нр - outer diameter of the pipe | ||||||||

| Ø Вн - Diameter of the internal channel of the pipe (conditional passage) | ||||||||

| TC - pipe wall thickness | ||||||||

D - The next indicator is the external diameter of the pipe and the thickness of its walls in millimeters.

D - Class of operation (parameter set GOST for domestic production of pipes) indicates the recommended scope of this type of pipe:

| Class of operation of polypropylene pipes | Fluid temperature (working / maximum), ºC | Purpose of pipes |

|---|---|---|

| XB | up to 20 | Cold water systems + |

| one | 60/80 | Hot water system with a maximum temperature of 60 ºC |

| 2 | 70/80 | Hot water system with a maximum temperature of 70 ºC |

| 3 | 40/60 | Underfloor heating systems with low temperature operation |

| four | 60/70 | Underfloor heating systems with high-temperature modes of operation, classic heating systems, heating with maximum coolant temperatures up to 60 ºC |

| five | 80/90 | Heating systems with high temperatures, including - with central heating |

Е - Next comes the parameter indicating the maximum allowable overpressure in the system that this pipe can withstand.

G - The last alphanumeric designation indicates the regulatory document (GOST, ISO or THAT, according to the standards of which these products are produced.

After receiving information about the classification of the pipe, you can immediately estimate the possible duration of its operation in the planned conditions. The following table will assist in this:

| Coolant temperature, ºС | Estimated lifetime | Pipe types | |||

|---|---|---|---|---|---|

| PN-25 | PN-20 | PN-16 | PN-10 | ||

| Maximum working pressure in the system (kgf / cm²) | |||||

| 20 | ten | 33.9 | 21.7 | 21.7 | 13.5 |

| 25 | 33 | 26.4 | 21.1 | 13.2 | |

| 50 | 32.3 | 25.9 | 20.7 | 12.9 | |

| thirty | ten | 9.3 | 23.5 | 18.8 | 11.7 |

| 25 | 28.3 | 22.7 | 18.1 | 11.3 | |

| 50 | 27.7 | 22.1 | 17.7 | 11.1 | |

| 40 | ten | 25.3 | 20.3 | 16.2 | 10.1 |

| 25 | 24.3 | 19.5 | 15.6 | 9.7 | |

| 50 | 23 | 18.4 | 14.7 | 9.2 | |

| 50 | ten | 21.7 | 23.5 | 17.3 | 13.9 |

| 25 | 20 | sixteen | 12.8 | eight | |

| 50 | 18.3 | 14.7 | 11.7 | 7.3 | |

| 60 | ten | 18 | 14.4 | 11.5 | 7.2 |

| 25 | 15.3 | 12.3 | 9.8 | 6.1 | |

| 50 | 13.7 | 10.9 | 8.7 | 5.5 | |

| 70 | ten | 13.3 | 10.7 | 8.5 | 5.3 |

| 25 | 11.9 | 9.1 | 7.3 | 4.5 | |

| thirty | eleven | 8.8 | 7 | 4.4 | |

| 50 | 10.7 | 8.5 | 6.8 | 4.3 | |

| 80 | five | 10.8 | 8.7 | 6.9 | 4.3 |

| ten | 9.8 | 7.9 | 6.3 | 3.9 | |

| 25 | 9.2 | 7.5 | 5.9 | 3.7 | |

| 95 | one | 8.5 | 7.6 | 6.7 | 3.9 |

| five | 6.1 | 5.4 | 4.4 | 2.8 | |

As mentioned above, polypropylene pipes are reinforced to make them resistant to elevated temperatures and baric loads and in order to drastically reduce the rate of silt or linear thermal expansion. In order to decide which option is better to choose - pipes reinforced with aluminum or fiberglass, it is worth to compare their main characteristics.

What is preferable to purchase - pipes with aluminum or fiberglass reinforcement?

Fiberglass began to be used to harden polypropylene pipes much later than aluminum foil. Products reinforced with this material are a three-layer structure, with the reinforcing layer located between two layers of polypropylene.

"Armopoyas" can consist only of fiberglass, or of a composite material containing in its composition fiberglass and polypropylene. In any of these options, the layers have excellent adhesion among themselves, practically becoming a monolithic structure.

Due to such a reliable soldering, the separation of the walls of a well-made pipe is even theoretically impossible.

This is just the layout. And in fact it’s unlikely to divide the construction of the pipe walls into layers

Fiberglass perfectly inhibits thermal expansion, which does not allow pipes to deform and stretch in any way when the temperature rises.

This type of reinforced polypropylene pipe is produced in various dimensional parameters. For example, products with a diameter of less than 17 mm are mainly used for the installation of a “warm floor” system, pipes with a diameter of 20 mm are well suited for domestic hot water distribution, and from 20 to 32 mm (sometimes more) for arranging heating circuits .

Connection of polypropylene pipes with fiberglass reinforcement is carried out by welding, sometimes by other assembly methods. Moreover, during welding, this type of pipe does not require a rather time-consuming cleaning operation, which greatly facilitates and speeds up the work. The absence in the construction of these pipes of metal elements eliminates the appearance of deposits of hardness salts, and the connections of all parts of the heating system become completely monolithic.

The diffusion process will necessarily lead to the acceleration of the corrosive processes of the metal equipment of the heating system - this is the boiler, the pump, the shut-off and control valves and other elements.

Since aluminum-reinforced products sometimes have a non-continuous foil layer, the danger of penetration into the coolant increases. In addition, aluminum itself is highly unstable to oxygen corrosion.

The fact is that pipes with an aluminum reinforcing belt are a laminated wall construction. If during the soldering process, a section of metal in contact with the coolant remains on the cut, then the process of wall separation can start from here. And this, in turn, will most likely lead to bloating at first, and then to a breakthrough of the pipe body.

Plot of increased vulnerability in polypropylene pipes, reinforced with aluminum foil

And for pipes with fiberglass reinforcement, which is almost a monolithic construction, this “Achilles heel” is absent.

And it is much faster and easier to weld pipes without stripping, especially since a special tool (shaver) is not needed for this purpose.

Исходя из рассмотренных характеристик данных, можно сделать вывод, что оптимальным вариантом для монтажа в систему отопления для подводки теплоносителя к радиаторам являются трубы PN-20 и PN-25 с диаметрами от 20÷25 мм. А вот при установке в систему отопления труб с меньшим диаметром, внутренний шов, образующийся в процессе пайки, может препятствовать свободному току теплоносителя.

Для монтажа стояков обычно выбираются трубы диаметром не менее 32 мм, иначе он тоже может оказаться мал для полноценного движения теплоносителя. На коллекторных участках системы могут использоваться и более крупные диаметры – ассортимент представленной в продаже продукции это позволяет.

В завершение публикации – небольшой обзор качественных полипропиленовых труб со стекловолоконным армированием, отечественного и импортного производства, заслуживших положительные отзывы профессионалов.

«METAK» — это российская компания производящая различную продукцию из полипропилена для систем отопления и холодного водоснабжения, в том числе и трубы, армированные стекловолокном, под маркой «METAK FIBER». Эта продукция отлично подходит для установки в высоко нагруженные системы отопления.

Высокое качество свойственно отечественным трубам компании «МЕТАК»

Трубы производятся в белом оформлении, имеют максимальную рабочую температуру 95 градусов, рассчитаны на рабочее давление в 25 бар при разрушающем – 50 бар.

Армированные стекловолокном полипропиленовые трехслойные трубы компании «МЕТАК» и соединительные детали к ним (фитинги) производятся в соответствии с ГОСТом Они используются для установки трубопроводов холодного и горячего водоснабжения, теплых полов, разводки систем и технологических трубопроводов, поэтому они могут иметь различные диаметры.

Вся продукция, трубы и необходимые комплектующие, производится в строгом соответствии с требованиями ГОСТ

Данная таблица предоставляет информацию о размерах производимых этой компанией труб со стекловолоконным армированием. Общей для всей продукции является длина, которая составляет 4000 мм.

| Наружный диаметр трубы, мм | Внутренний диаметр, мм | Толщина стенок, мм |

|---|---|---|

| 20 | 13.2 | 3.4 |

| 25 | 16.6 | 4.2 |

| 32 | 21.2 | 5.4 |

| 40 | 26.6 | 6.7 |

| 50 | 33.2 | 8.4 |

| 63 | 42 | 10.5 |

| 75 | 50 | 12.5 |

These products are great for heating systems of country houses and apartments in high-rise buildings. All products "METAK" meets all domestic and European standards and requirements established for these products, as they are manufactured on high-tech equipment under the strict supervision of qualified professionals.

The Czech company FV Plast specializes in the development and manufacture of polypropylene pipes for pressure water pipes for the supply of cold drinking water, hot water supply and heating systems. The company produces polypropylene pipes and fittings to them only in gray, with a reinforcing aluminum and fiberglass layer.

Company logo and product sample - characteristic gray

“FV Plast” was one of the first to start the manufacture of products reinforced with fiberglass - this product range has the name “FASER”.

Characteristics of FV Plast FASER pipes reinforced with fiberglass:

Representatives of the "family" of fiberglass-reinforced pipes "FV Plast FASER"

In addition to the pipes themselves, the company presents on the market all the necessary component parts to them, which allows material from one manufacturer to create heating circuits of any complexity with guaranteed ensuring its reliability.

Kalde is a Turkish leading manufacturer of modern heating and plumbing systems assembled from PPR pipes and components. The material of this company is distinguished by maximum protection against build-up and contamination inside the pipes during the entire service life. Reliable, lightweight, durable, comfortable and economical, Kalde systems are inert to corrosion and chemical attack. Available in the widest range of diameters - from 20 to 110 mm.

Very good reviews deserve products manufactured under this Turkish brand.

Kalde Fiber is a three-layered white-surface pipe made of polypropylene and reinforced with fiberglass. It has excellent heat resistance, with the upper limit of the temperature of the coolant, reaching 95 degrees. Even at such a temperature in the system pressure not exceeding 10 bar, the manufacturer decalizes the service life of at least 50 years.

In addition to the above, the company also produces polypropylene pipes of different types:

Kalde accompanies its pipes with a full range of connecting elements and shut-off and control valves

The range of components «Kalde» is very diverse and is provided for different, even the most complex heating circuits.

BANNINGER is a German company that manufactures products that are distinguished by true European quality and undeniable reliability in operation. The company produces polypropylene pipes and a full set of necessary components to them for the installation of heating circuits, hot and cold water. A distinctive feature is the unusual, emerald green color of polypropylene pipes “BANNINGER”.

The range of the company "BANNINGER" - real German quality

Products are distinguished by high plasticity, so they calmly react to high and low temperatures. The parameters of polypropylene parts are selected taking into account research on the fatigue properties of the material, during operation for 50 years, at a constant temperature of 70 degrees and pressures up to 10 bar.

Polypropylene pipe sample with fiberglass reinforcement of the brand "BANNINGER WATERTEC"

The company's assortment includes polypropylene pipes without reinforcing materials, as well as with aluminum and fiberglass layers. Within the framework of this article, samples of the “WATERTEC ” and “CLIMATEC” series deserve attention. Their use will provide the created contour of heating the guaranteed indicators of reliability and durability.

In conclusion, I would like to recommend the topic not to buy pipes of unknown manufacturers, who do not even mention their company name in product labeling. Saving a little, you can buy a product that does not last even one heating season, failing at the most inopportune moment. In such a situation, you will have to pay a much more serious sum for replacing the pipes of the heating system, repairing your own and, possibly, neighbor apartment.

Another little remark. One of the most frequently asked questions is the following: "What information does the color of the reinforcing layer located in the pipe wall bear." The answer is simple - no. The color of reinforcement is rather the “whim” of the manufacturer, the desire to distinguish their products against the general background.

The color of the reinforcing belt in the thickness of the polypropylene pipe wall will not tell you any useful information.

By and large, any fiberglass-reinforced polypropylene pipe itself is designed to operate at elevated temperatures. So there will be a reinforcing "ring" red, green, blue or gray - it does not matter. The main information is in the alphanumeric marking of the pipe and in its technical documentation, which, by the way, do not forget to get acquainted in the store when choosing a material.

Что бы оставить комментарий войдите

Комментарии (0)