Ceramic stones with transverse slotted voids walls, piers and pillars spread on a single-ligation system. Stones are laid with voids up on the solutions with mobility, which prevents the solution from flowing into the voids of stones. The thickness of the vertical and horizontal joints should correspond to the masonry joints. When laying from concrete and natural stones, a multi-row ligation system is used, but with stacking transverse knotted rows no less than in every third row.

In connection with the new requirements for thermal protection of buildings, significant structural changes must be made in the construction of exterior brick walls: their thickness is increased to 4 ... 5 bricks using only brick or to reduce the thickness, an additional thermal insulation layer should be introduced into the brickwork.

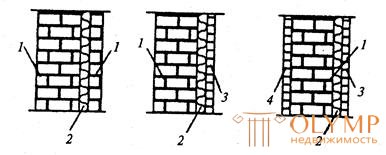

Fig. 12.1. Structural schemes of exterior brick walls: 1 brick masonry; 2 - insulation; 3 - plaster; 4 - drywall | In this regard, the outer walls are carried out in the form of three main structural schemes: an array, an array with insulation inside or on the wall surfaces (Fig. 12.1.). Array - the most common form, but according to the latest regulatory requirements to provide the required thermal protection wall thickness for |

Moscow’s climate zone should be more than 100 cm. This leads to a significant increase in brick consumption and an increase in wall mass. Now widely implemented the second and third schemes. When laying insulation in telesteny, the main part of the wall is initially laid to the height of a tier (1.5 ... 2 bricks). In the process of work, stainless steel pins with a diameter of 5 ... 8 mm are placed into the seams through two rows of bricks with a pitch of 50 cm. The end of the laying should be 3 ... 5 cm greater than the thickness of the insulation. After the laying, the insulation layer (expanded polystyrene, rokvul) is tied onto the rods at the height of the tier, then the inner part of the laying (0.5 ... 1 brick) is laid on the tier height, taking into account the protruding rods.

The third scheme provides for the installation of insulation from the outer or inner sides of the laying. Outside, as an element of the facade finish (Alseko and Texcolor technologies), they install slab insulation, fix the finishing mesh on top, arrange a protective layer on it and paint it. Insulation may be inside the wall structure when plastering the brick exterior mile masonry or finishing the facade with decorative panels, stained glass, artificial or natural stone. When installed indoors, the insulation is covered with plasterboard panels on a metal frame or, more rarely, plastered on a grid, then the surface is grounded and painted.

Что бы оставить комментарий войдите

Комментарии (0)