The layout of bricks and stones in the layers of masonry and the alternation of layers produced in a certain sequence, which is called the system of dressing the seams of masonry. Layers of laying of stones of regular shape are called rows of masonry.

Horizontal seams have an average thickness of 12 mm for bricks and 15 mm for natural stones, and vertical seams should be 10 mm thick for bricks and 15 mm for natural stones. The permissible thickness of individual seams is from 8 to 15 mm.

The thickness of the walls and pillars are multiples of half or whole brick or stone, with the exception of reinforced partitions in brick V4. In most cases, the brick in the brickwork is laid flat, i.e., on the bed, in some cases, for example, when laying the cornices, the brick is laid on the edge - the lateral side of the spoon.

The thickness of the solid brickwork is prescribed as a multiple of 0.5 bricks, so the walls can have the following thickness: half-brick -12 cm; brick - 25 cm; one and a half bricks - 38 cm; two bricks - 51 cm; two and a half - 64 cm; three bricks - 77 cm.

The height of the rows of masonry consists of the height of the brick or stones and the thickness of the horizontal joints of the mortar. With an average mortar thickness of 12 mm and a brick of 65 mm, the height of a row of masonry will be 77 mm, with a thickness of 88 mm thickened brick, respectively 100 mm. Thus, with a brick 65 mm thick by 1 m of brickwork, 13 rows are placed in height, with a 88 mm brick it is 10 rows.

The rectangular shape and manufacture of stones and bricks in accordance with the standards allowed to establish a certain order and the relationship of their location in structures that ensure the integrity and solidity of the masonry. Achieve this by stacking stones on the so-called masonry ligation systems.

All developed and applied in practice ligation systems comply with the rules of cutting masonry. For masonry, there is a ligation of vertical, longitudinal and transverse seams. Ligation of the longitudinal seams is necessary so that the masonry does not peel along the wall into thinner components and that the stresses arising from the applied load in the masonry are distributed evenly across the entire width of the wall. The ligation of transverse seams is necessary for a longitudinal connection between individual bricks, which ensures the redistribution of the load on neighboring sections of the masonry and preserve the solidity of the wall with possible uneven precipitation, thermal deformation, etc. The ligation of the transverse sutures is performed with spoon and butt rows, and the longitudinal suture is performed only with butt joints. The main used ligation systems: single-row, multi-row and four-row.

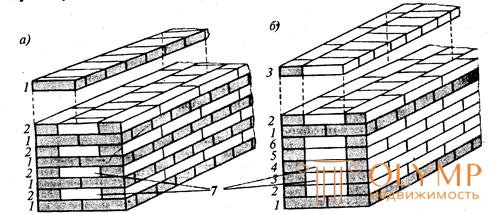

Chain masonry is applicable when laying walls of all types of bricks and stones. Masonry is performed by alternating through one butcher and spoon rows, with each vertical seam between bricks or stones of the lower row overlapping with bricks or stones of the next row (fig. 11.4, a). Vertical transverse seams with such a system of ligation overlap on U kirtichi due to the use of bricks of fours and threefolds and carrying out the dressing for longitudinal seams in half a brick.

Multi-row six-row masonry, in which transverse vertical seams overlap in each row, and longitudinal vertical seams only through 5 horizontal rows, i.e., the dressing system provides for alternating six rows of six brick rows in the outer milestones - one tychkovy and five lobster bricks (Fig. 11.4, b). With this laying, the transverse joints in adjacent rows of rows are shifted to V2 bricks, and the longitudinal overlaps are covered only with 6th-row bricks. The peculiarity of the laying is that five rows in a row are placed with one spoon along the wall, this is a significant advantage of laying in relation to the single row, since laying bricks in sludge is much simpler than rock miles.

The strength of multi-row masonry is less by 2 ... 5% than that of single-row masonry, but it has several advantages:

■ easier and faster execution of work;

■ work does not require three-quad bricks;

■ in the outer mile lay 1.3 times less than the whole brick;

■ the amount of filling in single-row laying is 25%, and in multi-row laying –42%;

use any brick battle for zabotki.

Fig. 11.4. The system of ligation of seams when laying walls with a thickness of two bricks: single row (chain); b - multi - row; 1 - tychkovy ranks; 2.6 - spoon rows; 7 - zabotka

Fig.11. 5. Facing walls of brick and ceramic stones: a - with multi-ligation; b - the same, with single row; a wall of ceramic stones with brick lining; d - the same, with facing ceramic stones; e - masonry without ligation of vertical seams of the outer mile; e - the same, with ligation of vertical seams within three rows of masonry | As a disadvantage of the ligation system, it can be noted that the masonry is significantly more difficult to perform in winter at low temperatures. This is due to the fact that freezing of the solution in longitudinal vertical seams can cause buckling of external or internal lay of laying with a thickness of 1 / 2kirpich that do not have transverse ligation to a height of five rows. Four-row masonry is used for masonry pillars and narrow walls with a length of up to 1 m. Cross vertical seams in three adjacent masonry rows are allowed to coincide. |

Pillars and piers should be laid out only from the whole selected brick.

Masonry brick start and finish tychkovymi rows. They are located in the places of support of beams, girders, trusses, floor slabs and coverings, in protruding masonry rows - cornices, corbels, regardless of the masonry sequence of rows of the adopted dressing system. Tychykovymi rows also link the milestones with zabotkoy, so they should always be made of a whole brick.

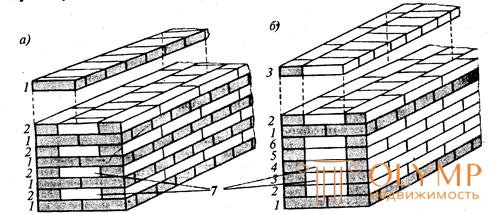

Types of masonry. Masonry walls with veneer is used to give the facade a better appearance and increase the resistance of the outer surfaces of the walls to atmospheric influences. Use facing brick, ceramic plates and natural stone with mandatory ligation of the entire masonry by the type of single-row or multi-row masonry (Fig. 11.5)

Masonry walls with brick and stone cladding of regular shape are used to decorate the facades of unique buildings and objects of mass construction, for the internal walls of vestibules, stairwells, underground passages, to replace labor-intensive plaster. The lining is carried out simultaneously with the laying of the walls or with a time shift with a special facing brick and ceramic stones of various processing and coloring. The most commonly used stones and bricks are as follows: ordinary face brick -250x120x65 or 88 mm, stones - 250x120x140 mm, three-quarters -188x120x140 mm.

Wall cladding with bricks and ceramic stones simultaneously with brickwork is performed by laying it with spoon rows and bandaging with the main brick by laying bonder rows with embedding bricks at a length of V2 in the monolith of the main brickwork. Allow the binding of cladding with the main using stainless steel pins. Apply various options for dressing facing layer with masonry walls of the array, but they must necessarily be linked, and be integral with the main masonry, performed on a single or multi-ligation system.

In the case of a single-row dressing system, the cladding of the facade plane is carried out by alternating between spoon and butched rows. Facing bricks are much more expensive than ordinary ones; for this reason, the method turns out to be the least economical, since half of the rows of facing bricks are pumped.

When building walls according to a multi-lane ligation system on the front side, five spoons are overlapped with one tychkovyh. Expensive face brick is used more efficiently.

Facing the walls of ceramic stones is carried out by placing in an array of two tychkovyh rows through five spoon, and when using facing stones - the row of a row alternate three spoon. To make the facing layer more architecturally expressive, stitch dressing may be performed with deviations from general requirements: vertical transverse joints may not be tied up along the entire height of the building or within 3 ... 5 rows of masonry.

Masonry walls of lightweight construction are used to reduce the consumption of bricks and the overall reduction of the masonry mass. The masonry consists of two parallel spoons with bandaging with buttings in 3 ... 5 rows, sometimes more. The cavity formed is filled with insulating filling, light concrete, blocks or insulation plates. For greater rigidity, with walls of two or less bricks, the bonded rows are staggered at different levels in staggered order. The use of lightweight masonry reduces the consumption of bricks by 30 ... 40%, significantly reducing the complexity and cost of work.

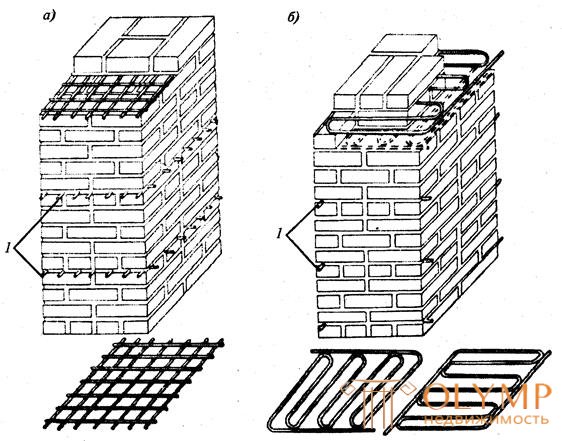

Reinforced masonry - its specificity is that to increase strength, reinforcing meshes or individual rods are placed in the seams (Fig. 11. 6). For transverse reinforcement used rectangular wire mesh or mesh "zigzag". The distance between the grid rods with their diameters of 3 ... 8 mm should be within 30 ... 120 mm. It is advisable to arrange the zigzag grids in two adjacent rows so that the arrangement of the rods in them is mutually perpendicular. Vertical grids are laid according to the project, but at least after 5 rows of masonry. Usually rectangular grids have a diameter of rods up to 5 mm, "zigzag" - from 5 to 8 mm. To provide a protective layer of the mortar, it is necessary that the thickness of the joints of the brickwork be no less than 4 mm in diameter over the wire.

For longitudinal reinforcement, the diameter of the compressed reinforcement should be at least 3 mm, and stretched - 8 mm. Reinforcement is carried out by rods or grids placed both in the masonry itself and next to it from the outside, fixing with the masonry in the second case is carried out with clamps embedded in the masonry. To protect the reinforcement from corrosion in dry conditions, the grade of the solution should be at least 25, in wet conditions - at least 50.

Figure 11.6. Reinforcement of brick pillars and walls:

and - rectangular grids; b - zigzag nets; 1 - protruding ends of the bars of the nets

Что бы оставить комментарий войдите

Комментарии (0)