Bricks are transported in a package way on pallets or container.

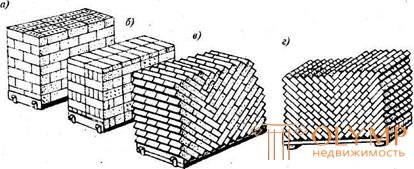

Fig. 12.4. Ways of laying bricks and stones on pallets: a - laying of ceramic stones with cross ligation on a pallet with hooks; b - laying bricks with cross-dressing on a pallet with hooks; (c) laying a herringbone brick on a pallet with hooks; d - the same, on the pallet with supporting bars | The batch method practically eliminates manual labor during the transportation of bricks from the factory to the workplace of a bricklayer. The main device with this method is a pallet-shield of boards, sheathed from the ends with steel corners with welded hooks. After firing, special bricks are loaded onto pallets, which are installed on vehicles with cranes. On |

Bricklayers' workplace bricks are served with metal cases, which are put on top of pallets and fastened with hooks. It is better to stack brick on trays “in the herringbone”, in this case they get a reliably connected package, for which no protective structures are required. Up to 200 pieces are placed on one pallet 0.52 x1.03 m in size. bricks. Pallets with triangular support bars at the ends of the shield are used when laying bricks in the herringbone, with stop plates at the ends for transporting ceramic blocks (Fig. 12.4).

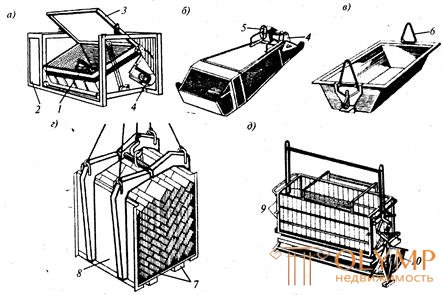

When the container method at the factory brick is placed in a universal container with a wood-metal pallet, which is placed from 100 to 180 pcs. bricks or one-and-a-half blocks (fig. 12.5, g, e). The container case after delivery of the brick to the work site is folded and returned to the factory.

With the batch method of transportation in comparison with the container cost is reduced by 10%, and the complexity of up to 20%.

Fig. 12.5. Masonry inventory:

a - installation for receiving and issuing a solution; b - jaw shutter bunker; in - mortar box; d - grab-case; e - self-locking grip; / - capacity for mixing the solution; 2 - engine compartment; 3 - cover; 4 - shutter for dispensing solution; 5 - steering wheel; b - loops for slinging; 7 - pallet with transverse bars; 8 - g-shaped half-case; 9 - frame capture; 10 - gripping device

Transportation solution . The preparation of the solution is carried out in factories or centralized mortar units. At the on-site mortar plants, the preparation of the solution is allowed when there is little need.

Typically, the solution is transported by dump trucks, tank trucks and in bunkers-distributors. The solution delivered to the object is discharged by a device for mechanical mixing and fed to working bunkers, tubs (Fig. 12.5, b, c) or by a mortar pump. The industry produces a wide range of mortar pumps with a maximum capacity of up to 6 m3 / h. Mechanisms are used with a large amount of brickwork and the rapid pace of work.

Mortar pumps allow the solution to be delivered horizontally up to 200 m or vertically up to 40 m, with a working pressure in the system up to 150 Pa. The solution is most often supplied with two risers, the second one is used to return the unused solution back to the bunker; clay is commonly used as a plasticizer additive.

The supply of the solution to the workplace can be accomplished using a dispensing hopper moved by a crane. From the bunker at the workplaces, bricklayers fill the mortar boxes, in which the optimal angle between the end wall and the bottom of the box allows you to recruit a solution with the least labor.

Brick and stones on pallets must be submitted to the workplace in advance, preferably the day before, the stock of materials must meet the need for brick for 2 ... 4 hours of work. The solution is fed to the workplace before starting work and periodically added as it is spent; solution in the workplace should be at 40 ... 45 minutes of work.

At insignificant amounts of work, delivery of dry mixes in paper bags or in bunkers to the construction site is applied.

Что бы оставить комментарий войдите

Комментарии (0)