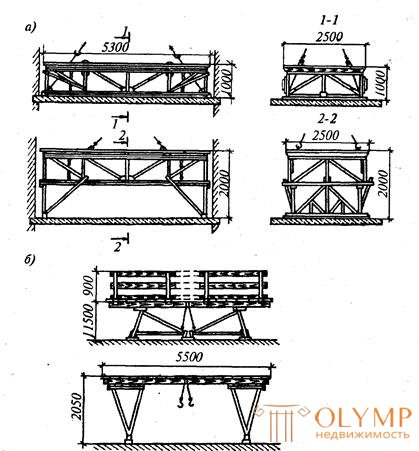

Articulated panel scaffolding consists of two welded trusses of triangular cross section, to which wooden bars and flooring are attached. When laying the second tier, the scaffolding rests on folding supports when their small trusses are connected in the middle

. Fig. 12.6. Scaffolding for masonry: a - inventory scaffolding; b - hinged panel scaffolding | scaffolding and the deck is at a height of 115 cm. By disconnecting the supports in the center and lifting the scaffolds with a crane, the folding supports at the expense of their own weight will straighten and, securing them with braces on the working floor, you can increase the height of the scaffolds to 205 cm. Portable scaffolding platforms consist of a metal support and flooring. They are used when laying the walls of staircases, walls of loggias, when working in cramped conditions. Rack-mount scaffolding is disassembled before rearrangement; for other types, changing the level of the working floor and rearrangement to a new one |

place carried out with a crane. To control the quality of the masonry between the working flooring scaffolding and erected wall leave a gap of up to 5 cm.

Tubular scaffolding - temporary devices designed for the construction of masonry on the entire height of the building. In addition to performing masonry, forests are used in the construction of single-storey industrial and agricultural buildings, plastering, cladding and painting walls, and other construction work. The most widespread scaffolding tubular non-bolt, tubular bolted and scaffolding of bulk elements,

Boltless tubular scaffoldings are a frame consisting of two rows of tubular struts with a height of 2 and 4 m and a diameter of 60 mm and crossbars of the same diameter and a length of 2 m with hooks and anchors for fastening to the walls (Fig. 12.7). On the top of the crossbars stack panel flooring with a thickness of 50 mm with dimensions in plan of 2.4x1.0 m and fenced with railings. In each rack from one end there is a bushing with a diameter of 48 mm, into which, when the scaffold grows, the next stand is inserted with the lower end. Through each meter in height, tubes with a length of 150 mm and a diameter of 26 mm are welded to the posts on four sides for fastening bolts, the bent ends of which are passed into these tubes. The joints of the racks are arranged in a running direction, for which the racks of 2 and 4 m in length are alternated on the lower first tier, and all subsequent tiers are mounted from the racks of 4 m long.

1-1

Fig. 12.7. Masonry scaffolding: and - tubular bezboltovy; 6 - boltless connection; in - bolted connection; / - stand; 2 -gel; 3 - hook welded to the bolt; 4 - pipes welded to the crossbar rack | When installing the first row of pillars on the ground or asphalt, laying pads or linings are placed on them, inventory shoes, in which holes are inserted into the racks. In the course of the masonry racks of tubular scaffolds are increased, tied with crossbars and shifted flooring from the lower tiers. Forests can have a height of up to 40 m. Tubular bolted woods also consist of racks and girders. Racks are interconnected using sleeves, and girders with racks are bolted to the clamps that |

allows you to lay the girders in height anywhere, as well as equip the protruding parts of the building with forests and compensate for the existing slopes of the land at the buildings. Such scaffolding is more universal than bolt-less, but more labor-intensive during installation and dismantling due to the large number of elements and bolted joints.

The scaffolding of the bulk elements consists of vertical shelves and working floor panels with fencing. All elements of the forest are assembled and disassembled with the help of cranes. Such forests have been used for masonry walls of one-story industrial buildings up to 14.2 m high.

Что бы оставить комментарий войдите

Комментарии (0)