Use this type of waterproofing with a slight (up to 0.2 MPa) groundwater pressure. The purpose of the paint insulation is to protect the structures covered with earth from capillary moisture. This type of waterproofing is used on monolithic and precast concrete structures with capillary suction of groundwater or short-term watering. In case of constant watering and in the presence of aggressive water, it is used to isolate a composition based on epoxy resins, provided that the structures and parts of buildings are sufficiently crack-resistant (Fig. 19.2).

Apply to the device of a waterproofing paint:

• bitumen, tar and bitumen-polymer compositions;

• polymeric paint formulations;

• oil and oil-based paints and varnishes;

• mineral-based paint formulations.

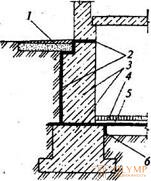

Fig. 19.2. Painting waterproofing at groundwater capillary suction: 1- blind area; 2- painting waterproofing; 3 base; 4 clean floor; 5-cement screed; 6- waterproofing deformation seam | The most effective waterproofing materials based on polymers: epoxy varnishes, paints and mastics, paints and varnishes containing rubbers and their derivatives, chlorsulfopolyethylene and other polymers. Mineral-based paint formulations have been applied, these include paints manufactured on the basis of cement (polymer cement) and liquid glass. To increase the protective ability and deformability of polymer-cement paints, a thin layer of diluted latex is pre-applied on the surface to be painted. |

Mineral-based paints are designed to finish concrete surfaces and protect them from slightly aggressive environments. They have high water, frost and weather resistance compared to water-based paints.

Paint waterproofing is recommended for crack-resistant structures. To increase its reliability, it is reinforced with glass fabrics, burlap and other rolled materials.

Paint waterproofing is a continuous waterproof layer, made of cold or hot bitumen mastic and synthetic resins. Materials for paint waterproofing on the basis of bitumen are prepared, as a rule, in the factory and used on construction sites in finished form. Delivery is carried out by a special vehicle, equipped with means of supplying waterproofing material to the place of use (road sprayers, bitumen, etc.).

Polymeric waterproofing materials are usually delivered to the place of use as components in hermetic tanks: a mixture of epoxy resin with a solvent and a fixer and separately - a hardener. Mixing the components is carried out immediately before applying to the surface in a volume designed for 30 ... 40 minutes of work with waterproofing material.

Ethylene lacquer has been used as a type of polymer waterproofing material. Lacquer or paint based on it is delivered to the work site in hermetic containers. Ethylene varnish in its pure form is used only for priming the base. When preparing ethylene paints and in order to give them greater crack resistance and strength, a plasticizer (bitumen or PVC lacquer), pigments, fillers (quartz sand, fiberglass, short fiber asbestos) are added to the ethylene varnish.

On the painted surface can be applied waterproofing material in hot form - bitumen, tar, pitch without any additives or solvents. The same materials, diluted with solvents - gasoline, kerosene, diesel oil, become mastics, in which for strength you can add fillers - asbestos and glass fibers in an amount up to 10% by weight, chalk, limestone or slag with a particle size of not more than 0.3 mm .

The technology of the device waterproofing paint. The technological process, regardless of the types of materials used and the functional purpose of the coatings, consists of the following main technological operations: surface preparation, application of painting waterproofing and coating formation (drying, curing, decorative finishing).

In preparing the surface, the efflorescences, mortar drips, corrosion products, all stains are removed with scrapers, steel brushes, and emery wheels. Sinks, pores and cracks on the surface of concrete are sealed with cement-sand mortar. The reinforcement protruding to the surface, if necessary, is cut off or cleaned of rust, the cavity is sealed with a solution. Dusty constructions are cleaned with vacuum cleaners, compressed air, hair brushes, the surface is washed and dried.

Before applying the paint waterproofing the prepared surface is primed. The primer is necessary for providing better adhesion to the surface and is made with a liquid solution of a waterproofing material that penetrates deeper into the pores and surface irregularities, which then ensures a better adhesion of the waterproofing.

This type of waterproofing is applied in 2 ... 3 layers. Painting insulation is performed in thin layers of 0.2 ... 0.8 mm, and coating one - with thicker layers of 2 ... 4 mm. For brushes, ordinary brushes are used, painting is more often performed with spray guns or a spray gun (Fig. 5.3, 5.4). With insignificant amounts of work and in hard-to-reach places, a manual method of painting is possible, brushes are unacceptable with quick-drying materials. Use pneumatic method of applying waterproofing with a distance from the spray head to the surface of 25 ... 30 cm and airless (hydrodynamic) method at a distance of 35 ... 40 cm, the spray should be located perpendicular to the surface.

The application of painting waterproofing is carried out with strips with overlapping strips. Workers performing this type of waterproofing are required to work in overalls, when using synthetic materials, in addition in protective glasses and respirators, and in some cases - in gas masks.

Painting (obmazochnaya) waterproofing is not enough plastic and elastic, so it cracks during deformation, settlement and vibration of structures. This type of insulation can not be used for crack-resistant structures and for buildings that have not yet ended sediment.

Considering the noted disadvantages of this type of waterproofing, a protective structure should be laid on the filled waterproofing coating:

• on horizontal surfaces— in the form of a cement or asphalt screed with a thickness of 3 ... 5 cm;

• on vertical surfaces - in the form of cement plaster on a metal grid.

For paint waterproofing developed rubber compounds based on hydrocarbon polymers. The materials are applied to the surface and applied by airless spraying with heating, which, unlike traditional methods, ensures the uniform formation of a polymer film on structures of various shapes and the formation of a coating with high surface quality. Full moisture resistance and high protection efficiency is achieved. The materials on this basis are environmentally friendly, do not contain highly toxic and carcinogenic substances. The coating is characterized by improved resistance to aggressive components of soil environments, has a high adhesion to brick, concrete, metal and other building materials. The exceptional elasticity of the coating (up to 1800%) allows you to avoid the appearance of defects on its surface, even with significant

base deformations (formation of macrocracks up to 1 cm thick) and thereby maintain a high level of protective properties during the operation of buildings. If you need additional protection of the coating from mechanical damage, you can install (sticker) protective panels after the installation of the coating after a few hours.

base deformations (formation of macrocracks up to 1 cm thick) and thereby maintain a high level of protective properties during the operation of buildings. If you need additional protection of the coating from mechanical damage, you can install (sticker) protective panels after the installation of the coating after a few hours.

Due to the adjustable heating of the material in the nozzle to a temperature of 70 ° C, it can be applied to the surface at temperatures up to - 20 ° C, operating temperature from - 40 to + 60 ° C, the warranty period of operation is more than 30 years.

Что бы оставить комментарий войдите

Комментарии (0)