This type of waterproofing is used at hydrostatic pressure up to 3 MPa. There is plastering and cast asphalt insulation.

Plastering asphalt waterproofing is based on fine-grained asphalt concrete, which has the following varieties:

• hot hard, designed for waterproofing floors with wet cleaning;

• hot cast - waterproofing of floors in wet areas (baths, laundries, etc.);

• cold - insulation of concrete, reinforced concrete, stone and brick structures, basement walls, tanks and pools.

Plastering asphalt waterproofing serves to protect horizontal and vertical surfaces and is used in the form of asphalt plasters, plaster mortars and asphalt mastics.

The composition of asphalt plaster includes bitumen, sand with a particle size of up to 2 mm, powdered aggregate (limestone, dolomite, ash CHP), fibrous filler (asbestos and fiberglass) and water.

Asphalt plaster has four varieties:

• hot mastic consisting of 35% by weight of bitumen BN 70/30, fine asbestos 8% and 57% powdered filler;

• cast hot solution contains 20% bitumen BN 70/30, fine asbestos 5%, powdered filler 35% and up to 40% quartz sand;

• cold solid plaster includes 80% of bitumen paste, 20% of powdered filler and additionally up to 10% of water;

• cold liquid plaster consists of 60% bitumen emulsion, 8% fine asbestos, 17% powdered filler and 15% water.

A special feature of asphalt-polymer plastering hot solutions is the inclusion of, in addition to bitumen (40 ... 45%), mineral powder (10%), asbestos (5 ... 10%), quartz sand (40%), and also polymer rubber, latex and rubber glue.

To protect coatings from process and atmospheric waters, coatings from cold asphalt mastics have been used, consisting on average 50 ... 60% of bitumen and 40 ... 50% of mineral filler, which can be lime, limestone, asbestos, cement latex

Plaster asphalt waterproofing arrange in the form of a continuous coating of hot asphalt (bitumen) mastic, mortar or cold emulsion mastic and pastes. Under the hot compositions of the surface are primed with liquefied bitumen, under the cold - with bitumen emulsions. Bituminous cold primer includes 30% bitumen and 70% gasoline.

Waterproofing vertical surfaces . The process of applying hot asphalt compositions is mechanized and is carried out with the help of asphalt mixers and mortar pumps. The compositions (a mixture of hot bitumen mastic, sand and fillers) are applied in several batches intermittently to cool the previous batt for 1 ... 2 hours. The asphalt cement nozzle is kept perpendicular to the insulated surface at a distance of 50 cm from it. The pressure of compressed air in the unit in the range of 0.5 ... 0.6 MPa. Hot structures are applied to vertical surfaces in layers with a thickness of 5 ... 7 mm from top to bottom in tiers of 1.5 ... 1.8 m in height with a length of the grab no more than 20 m. The pairing of the grips in each layer is only overlapped, at least 200 mm wide , and in adjacent layers only in a run, for a distance of at least 300 mm. Asphalt waterproofing is applied on dry and clean vertical surfaces with a total thickness of up to 20 ... 25 mm.

Plastering asphalt insulation should have a protective fence that prevents its premature destruction. Without a safety fence, it is allowed to perform work only on surfaces accessible for inspection and repair.

Waterproofing from cold asphalt mastic on a vertical surface, first primed with emulsion paste, is applied in layers of 4 ... 5 mm nozzles using mortar pumps; each subsequent layer is applied after the previous one is set. The mastic is applied from top to bottom, the work is simultaneously performed on the working section with a height of 2 .., 2.5 m. The insulated surfaces are broken into hooks up to 20 m long. The adjacent areas are mated by overlapping within 200 ... 300 mm, the interface is paired in height Plots should not be at the same height.

Each subsequent layer is applied after drying the previous one. With a positive ambient temperature and in dry weather, the freshly laid layer is kept for 1 ... 3 hours, and during cloudy conditions - 24 hours. After drying, the insulation layer becomes light gray. In the cold season it is impossible to introduce antifreeze into cold asphalt compounds, since this leads to an increased water absorption of the coating.

Waterproofing horizontal surfaces . Cast asphalt insulation is a continuous waterproof layer of asphalt mass with a thickness of 30 ... 50 mm on horizontal or inclined surfaces. The basis for cast insulation are concrete, reinforced concrete, stone structures, compacted soil with embedded gravel. Insulation is used for the construction of the blind area of buildings, in the form of a leveling layer under the roof and it is made of asphalt concrete, a mixture of bitumen with sand, gravel or gravel.

Hot asphalt insulation, consisting of a mixture of hot bitumen mastic, sand and fillers, is applied on horizontal surfaces with asphaltometry. If a cast mixture is used, then on horizontal surfaces the mixture is poured and smoothed with a scraper.

Hot asphalt compounds are applied on horizontal surfaces in layers with a thickness of 7 ... 10 mm. The pair of clamps in each layer only overlaps a width of at least 200 mm, and in adjacent layers only at a distance of at least 300 mm. The work is carried out in sections, the contact zones of the previously laid and new waterproofing 100 ... 200 mm wide are heated, brought to the melting point (140 ° C), the area is compacted and smoothed.

Waterproofing with cold asphalt mastic consists of a mixture of emulsion paste with fibrous mineral fillers. It is applied to horizontal surfaces by spilling or spraying, followed by leveling with a layer of 7 ... 8 mm. The first layer is set and the reinforcing material is rolled in (fiberglass or antiseptic burlap), and another two or three layers of asphalt mastic are applied on top until the design thickness of the waterproofing is within 15 ... 20 mm.

When applied to horizontal surfaces, compaction is carried out with light rollers or with electric motorized vibrating tillers.

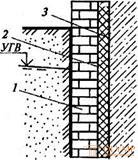

Cast waterproofing is arranged by pouring waterproofing materials in the gap between the insulated surface and the protective, clamping wall (Fig. 19.6). Pre-parallel to the insulated surface install a protective wall. Hot asphalt mix is poured into the cavity along the width of the given waterproofing, using possible means of its compaction (Fig. 19.7,19.8). In winter, mastered the waterproofing coating of the roll-up roll materials. Such sticking is allowed at an ambient temperature not lower than - 20 ° С on the leveling screed of hot sandy asphalt concrete with its temperature at the moment of laying exceeding the air temperature (with reverse |

Fig. 19.6. Cast waterproofing: 1 - security fence; 2 — cast waterproofing 3-insulated construction |

familiar) at least twice.

At low ambient temperatures, leveling screeds from hot cast asphalt under the roll roofing are performed in square sections with a side size of up to 4 m, limited by lighthouse bars. The blind area around the buildings is arranged only from cast asphalt year-round. The temperature of the asphalt at the beginning of laying should be not lower than 160 ° C, at the end - not lower than 140 ° C, compaction of the coating with mobile rollers.

Fig. 19.7. Cast asphalt waterproofing: 1 - foundation, 2-painting waterproofing; 3 heated gravel; 4-concrete preparation; 5- asphalt blind area; 6- vertical elastic layer on a bitumen base; 7-waterproofing of the wall, coupled with the insulation of the floor; 8- masonry wall |

Fig. 19.8. The device of the vertical cast asphalt waterproofing: 1- cavity under the fill; 2- primed surface; 3-cavity, filled with waterproofing mastic; 4 backfill; 5 - protective wall |

Что бы оставить комментарий войдите

Комментарии (0)