This waterproofing is used for water pressures of more than 40 m. Its main purpose is to insulate structures that are in harsh operating conditions, including ensuring constant dryness in rooms at a high temperature of the insulated structure, and insulation pits. Apply steel and aluminum sheets with a thickness of 2 ... 6 mm, rigid plastic and vinyl sheets; The latter are used to protect tanks from corrosive environments. High-density slabs of reinforced concrete, reinforced cement and glass cement are used.

The use of these materials is due either to unfavorable operating conditions (strong tearing pressure, aggressive environment, difficulties or lack of repair) or special requirements

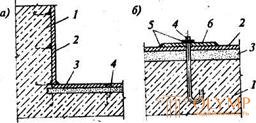

Fig. 19.9. Precast metal sheet insulation: a - diagram of the isolation device; b — isolation mounting scheme; 1- insulated structure; 2- metal sheet; 3-layer cement-sand mortar; 4-anchor; 5 weld; 6 - clamping flange | - increased mechanical strength, architectural expressiveness, etc. Galvanized or low-alloyed (stainless) steel, rolled and sheet products from polymeric materials such as vinyl plastic, plexiglas, textolite, polystyrene, polypropylene, polyethylene, fluoroplastic and fiberglass plastics of furan, polyester and epoxy are used for the device of the waterproofing team. Arrange metal insulation on the internal and external surfaces of structures. However, internal waterproofing is preferable to external waterproofing. |

as in the event of the slightest leakage, they can be identified and eliminated without much effort and cost associated with the construction of special pits or wells around the underground structure.

Metal insulation at the base of the facilities is carried out by asphalt preparation. The outer surface of metal sheets should be protected from corrosion by paint or plaster on the grid. Sheets are joined by welding overlap or end-to-end with two front seams, which provide a joint that is of equal strength to the base metal, and are fixed to an insulated surface using embedded parts and anchors (fig. 19.9). To protect against corrosion, the open surface is ground and painted twice with anti-corrosion paints or plastered with cement mortar on a metal grid. Cement is injected into the space between the structure and metal insulation under pressure for greater sealing between them.

Fig. 19.11. Combined isolation from polymeric sheets: 1 - polyvinyl chloride coating; 2-insulated structure; 3- an overlay from a polyvinyl chloride strip, welded along the edges to the main insulation; 4 dowel; 5 traffic jam |

Fig. 19.12. Composite insulation of polymeric sheets of profiled polyethylene: 1 - welded joint of polyethylene team insulation; 2-shaped polyethylene-new sheet; 3-reinforced concrete base; 4-cement-sand screed; 5-profiled polyethylene sheet of horizontal insulation; 6- concrete preparation; 7 crushed stone base |

Insulation of polymer sheets used to protect structures from aggressive external environment. Sheets are welded with hot air or high-frequency currents, sheets are attached to the insulated surface on special adhesives, bolts and other fasteners are used, provided for in the project (fig. 19.10).

Monolithic and precast reinforced concrete structures are insulated with sheet-shaped polyethylene with anchorage (Fig. 19.12). By means of anchors mechanical fastening of sheets to concrete is provided. Anchors are embedded in a concrete structure or in cement-sand mortar joints between prefabricated elements. In the necessary places above, the applied coating is covered with strips of sheet polypropylene, which are welded to the main insulation.

Slabs of reinforced concrete, reinforced cement and glass cement are used as waterproofing in the manufacture of structures and structures of monolithic reinforced concrete, at the same time these plates serve as permanent formwork. The waterproofing slab structures are fixed to the main structures with special reinforcement outlets or pins that are laid into the slabs during their manufacture.

Prefabricated waterproofing is different from all types of insulation the most expensive and labor intensive device, but in some cases this is the only possible type of waterproofing.

Что бы оставить комментарий войдите

Комментарии (0)