The method of punching with the use of a percussion-cable drilling machine (Fig. 6.1) has been applied. First, the leader well is drilled to a depth of / / 2 the length of the future pile, then the well is punched with a percussion projectile to the required depth. A hard concrete mixture is loaded into the lower part of the well with a column of 1.5 ... 2 m and a broad heel is arranged at the base of the pile with tamper strokes. A casing is installed at the wellhead, the reinforcement cage is mounted and the upper part of the pile is concreted.

The method of vibroforming piles is characterized by the presence of a vibroforming machine. Its hollow tip has blades in the lower part and is connected through a rigid bar with a vibratory driver. Under the action of the latter, the tip is immersed in the soil and forms a well, which, as the tip is submerged, is filled with concrete mix from a bunker installed above the wellhead. After the well has been drilled, the tip is slightly raised, while its blades open, the concrete mixture falls through the tip cavity to the bottom of the well. Instead of self-opening flaps, a lost cast-iron shoe can be used.

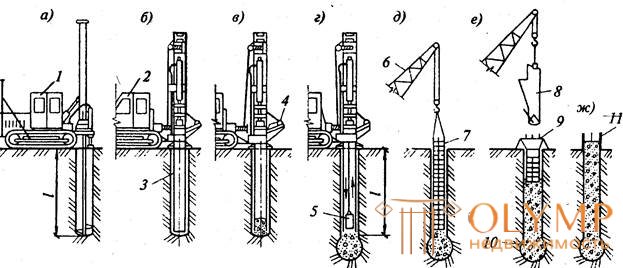

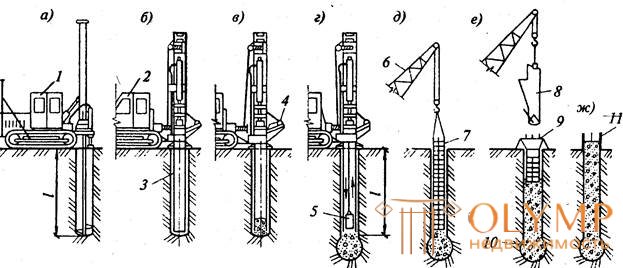

Fig. 6.1. Technological scheme of the bored piles with the stamped

fifth:

a - well drilling; b - installation in the well casing; в - backfilling of a rigid concrete mix into the well; g - tamping concrete mixture into the base; e - removing the casing and installing the reinforcement cage; e - concreting the pile shaft with compaction with a deep vibrator; g - device of pile cap formwork; 1 - drilling machine; 2 - working mechanism with attached equipment for the device of the broadened heel; 3 - casing; 4 - tray for loading rigid concrete mix; 5 - tamper; 6 - jib crane; 7 - reinforcement cage; 8-tack with a concrete mix; 9 - funnel; 10 - stamped broad heel; 11 - formwork ogolovka

Rammed piles are used in dry bonded soils. A steel casing with a removable reinforced shoe at the end is immersed to the design point into a drilled well using a vibrator head mounted on an excavator. The cavity of the pipe is filled to 0.8 ... 1.0 m with a concrete mixture, compacted with a special tamper bar suspended from a vibratory pile driver (Fig. 6.2).

Fig. 6.2. Technological scheme of the machined piles: a - well formation; b - laying the first portion of the concrete mix; (c ) compaction of a concrete mix with a ram rod, rigidly connected with a vibratory pile driver; g - laying and compaction of subsequent layers of concrete mix; e - removing the casing and installing the reinforcement cage in the pile head | As a result, the shoe together with the concrete mixture is pressed into the ground, thus forming a broadened heel. The casing pipe is filled with a concrete mix in portions with constant compaction. As the well is filled with a concrete mix, the casing is lifted by an excavator while the vibrator is running, which significantly reduces adhesion of the pipe to the concrete during its extraction. Frequently rammed piles are arranged by driving a casing into a test well bore along with |

put on the end of a cast-iron shoe that remains in the ground (Fig. 6.3.).

Fig. 6.3. Technological scheme of frequency-packed piles: a - casing immersion; b - installation of the reinforcement cage; in - the flow of the concrete mixture into the cavity of the pipe; g - removing the casing with simultaneous compaction of the concrete mix; 1 - casing; 2 - pile driver; 3 - double action hammer; 4 - reinforcement cage; 5 - tub with a concrete mixture; b - receiving funnel; 7 - cast iron shoe | Loading the concrete mixture in the casing carry out portions in 2 ... 3 doses. The pile section is formed and the casing is extracted from the well with a double-acting hammer that transmits forces through the casing. The casing pipe with a cast-iron shoe under the action of hammer blows is immersed in the ground to the design mark. Plunging, the pipe expands the soil particles and compacts it. When the pipe reaches its lowest point, the reinforcement cage is lowered into its cavity (if necessary), then through a funnel from the vibro-bed, a hard concrete mixture with a draft of 8 ... 10 cm is fed into the cavity of the casing. while the shoe is |

Calcium under the action of the concrete mixture pressing on it, which begins to fill the well. A double action hammer connected to the casing at the same time produces frequent pair strokes directed up and down alternately. From blows directed upward in 1 min, the pipe is removed from the soil by 4 ... 5 cm, and from blows directed downward, the pipe is precipitated by 2 ... 3 cm. The tamping of the concrete mixture entering the well under its own weight is carried out due to the impact of the lower edge of the casing and the friction of the concrete against the pipe wall as a result of the vibration impact of the hammer, in connection with which the entire concrete mix is constantly in the process of vibration and as a result turns out to be well compacted. As a result, the soil is compacted in the lower part of the well, a part of the concrete mix is pressed into the walls of the well, increasing their strength.

Such a tamping of concrete in the casing continues until the complete extraction of the pipe from the ground. If necessary, external vibrators are fixed on the extracted casing pipe, which allow to better seal the upper layers of the concrete mix. Frequently rammed piles can be made reinforced. Reinforcement is carried out by calculation, but in most cases the reinforcement cage is used only in the upper part of the pile for connection with the reinforcement of a monolithic grillage.

Fig. 6.4. Sand device layout (soil) ramming piles: a - casing immersion; b - pipe extraction; in - drop-down tip; 1 - vibrating immersion; 2 - an aspiration pipe; 3 - hinge; 4 - tip flap; 5-ring | If the reinforcement is provided for the entire height of the pile, then the reinforcement cage is lowered into the casing before concreting. Sand piles - the cheapest way to compact weak soils. A steel casing pipe with a shoe is immersed in the ground with the help of a vibratory pile driver (Fig. 6.4). Having reached the design mark, it is partially filled with sand, when the casing is lifted due to the mass of sand, it is separated from the shoe, and extracted with a vibro-immersion to the surface, while the soil is compacted from the vibrations. Additional and efficient compaction can be achieved by shedding water. Apply pipes |

a layer of sand with a height of 1.0 ..1.25 m. The method is applicable for wells up to 7 m deep.

Что бы оставить комментарий войдите

Комментарии (0)