Concrete piles. Primer-concrete piles have been used, which are arranged with the help of drilling rigs with a hollow drill rod, which has a mixing drill at the end with special blades that are simultaneously cutting and mixing the mixture. After drilling a well in weak sandy soils, a water-cement slurry (solution) is fed to the hollow rod under pressure from the mortar mixing plant. The drill rod slowly rises upward during the reverse rotation, the soil is saturated with cement mortar and additionally compacted with a drill. The result is a cement-sand pile, made on site without excavation.

Lead piles. Quite often pits for buried constructions have to be arranged near existing buildings. Driving of piles and sheet piling can lead to their deformation due to the resulting dynamic effects. When constructing bored piles, where the casing is immersed with an advance sampling of soil from the pipe cavity, the soil mass may leak from under adjacent foundations, which can also lead to deformations of existing structures. The use of the methods “wall in the ground” or the use of clay solution for immersion of pipes leads to an increase in the cost of the project.

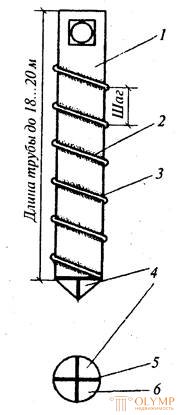

Fig. 6.5. Scheme of the pile-driving screw: 1 - metal pipe; 2 - welding coiling with a pipe; 3 - winding of reinforcement with a diameter of 10 ... 16 mm with a pitch of 200 ... 400 mm; 4 - cruciform deaf or lost tip; 5-cross; 6 - metal disc | With these methods, there is a violation of the natural underground environment and its equilibrium, which can lead to undesirable results or to a serious increase in the cost of construction. In cases of dense building, it is advisable to apply the method of drilling piles. The essence of the method is that the metal pipe is not hammered into the ground, but is screwed down (Fig. 6.5). A narrow auger of fittings with a diameter of 10 ... 16 mm with a pitch of 200 ... 500 mm is wound on the pipe in the factory. Depending on soil conditions, the pipe can be equipped with a plug with rippers, deaf or lost, allowing, if necessary, to prevent water into the pipe body. When screwing the pipe, the surrounding soil is partially compacted, about 15 ... 25% of it is squeezed out. If the pipe in the lower part is deaf, then after screwing up to the design elevation, the reinforcement cage is inserted into it and it is filled with concrete. For pipes with a lost tip, a reinforcement cage is inserted into it, the pipe is filled with concrete, the pipe is unscrewed during the setting of concrete, the shoe on which the reinforced concrete bored pile rests remains in the ground. For particularly dense soils, it is possible to pre-drill a well to a somewhat shallower depth (up to 1 m) and the diameter of the well must be less than the diameter of the pipe. Diameter |

In recent years, foundations have become widespread in the form of powerful deep-laid supports with a large bearing capacity, constructed with the help of special machines (Fig. 6.6.).

In recent years, foundations have become widespread in the form of powerful deep-laid supports with a large bearing capacity, constructed with the help of special machines (Fig. 6.6.).

Fig. 6.6. Technological scheme of bored piles with a diameter of 2 ... 3.5 m: and - installation of the drilling machine; b - well penetration; in - cleaning of a face; g - installation of the reinforcement cage; e - installation of a concrete pipe; e - concreting piles; 1- drilling rig; 2 - casing; 3 - grab bucket; 4 - reinforcement cage; 5 - concrete pipe | The development of the soil is carried out using a grab bucket inside the lowered casing. During the development of the soil bottom end of the pipe must be below the bottom of the well. Stripping of the face is made with a grab bucket. After the reinforcement cage is installed in the well, concreting is carried out using the method of vertically moving pipe; the depth of the concrete pipe in the concrete mix must be at least 1m. |

Что бы оставить комментарий войдите

Комментарии (0)