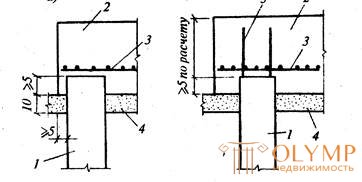

The construction of the grillage and the technology of its device accept, depending on the type of piles. Rostverka unite a group of piles into one design and distribute the loads from the structure on them. They most often represent a continuous tape along the entire contour of the building in plan, including the interior walls. When using reinforced concrete piles, grillages can be made of monolithic and precast concrete (Fig. 6.7).

Fig. 6.7. Connection of a pile with a grillage: a - free support; b - rigid support; 1 - pile; 2 - grillage; 3 - reinforcing mesh; 4 sandy training; 5 - release of reinforcement from the pile | Depending on the type of building or structure, grillages are divided into high and low. When driving piles, the heads of which, after driving, may be at different elevations, it is necessary to perform time-consuming operations to align the heads of piles before installing the grillage. To do this, it is necessary to cut down (cut off) concrete piles under a certain level, cut or bend their reinforcement. |

Cutting piles. Wooden piles and sheet pile are cut with mechanical or electric saws, steel piles with autogenous or gas cutters, in reinforced concrete piles, head-breaking concrete is usually destroyed with the help of pneumatic breakers. It is more effective to use punches for these purposes - installations for cutting heads of piles (Fig. 6.8), consisting of a rigid closed frame, lowered and clamped on a pile, a movable frame, removable teeth and a hydraulic jack with a piston. The installation kit includes several pairs of punches for piles with different cross-section sizes. The maximum working force is 200 tons, the working stroke is from 10 to 50 cm, the installation capacity is cutting heads 15 ... 20 piles per hour.

Fig. 6.8. Installation scheme for cutting heads of piles: 1 - pile; 2 - teeth; 3 - installation frame; 4-piston; 5 - hydraulic jack; b - bed | Piles when diving sometimes deviate in the plan, with a multi-row or cluster arrangement of piles, these deviations do not cause complications when constructing grillages. If there is a single row arrangement of the piles and part of the section of the individual piles goes beyond the boundaries of the future grillage, then in this case it is necessary to arrange a monolithic grillage and special projections in the grillage to include these piles in it. |

When preparing heads of stuffed piles for arranging precast grillages, check the top surface on the level and, if necessary, level the bearing surface of the piles using concrete mixture or cement mortar. Themselves reinforced concrete beam grillage installed on the leveling the filling of sand or slag, starting from the corner of the building, and perform installation work strictly on the grips. The elements of the precast grillage are connected with the short piles of the joint in welding with grouting joints.

Что бы оставить комментарий войдите

Комментарии (0)