Temporary strengthening of the walls of the grooves. During the construction of the underground part of buildings and structures, special requirements are imposed on the slopes and walls of the excavations. The need for their attachment, as well as the attachment design, depend on the hydrogeological conditions and the design of the underground part of the erected structure.

Vertical walls in soils of natural moisture in the absence of groundwater are allowed without fastening: with a depth of excavations in sandy and coarse-grained soils of not more than 1 m, in sandy-earth loams -1.25 m, in loams and clays - 1.5 m, in very dense soils 2 m.

At greater depths to prevent collapses and landslides of the walls of the grooves arrange slopes, the parameters of which are determined and regulated by the SNiP. The need to install slopes leads to a significant increase in the size of the earth structure and, accordingly, the volume of soil development, an increase in material and labor costs.

To reduce the volume of earthworks, as well as in cases where the development of slots with cavities is impossible because of the constraints of the site or the presence of groundwater, arrange the notches with vertical walls.

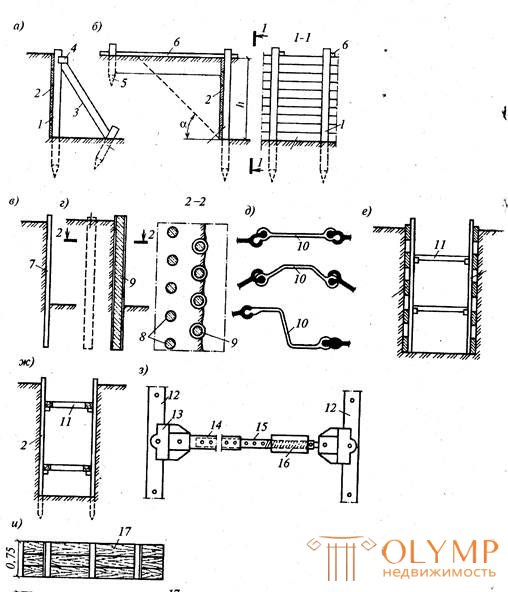

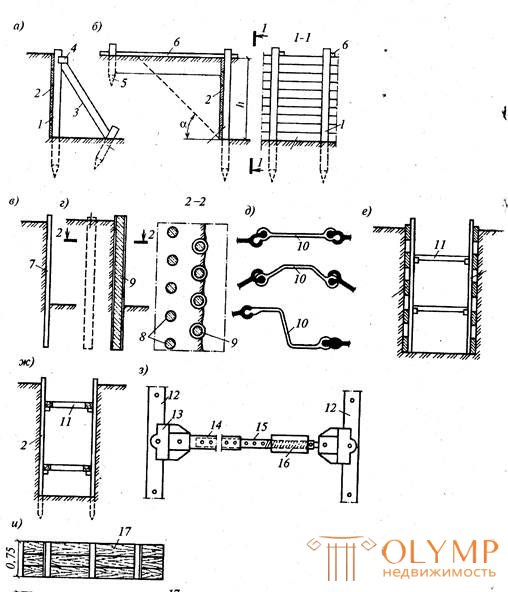

Temporary fixing of the walls of the earthen structure can be made in the form of wooden or metal tongue, wooden shields with supporting posts with a braced mounting of the walls (Fig. 6.9).

Sheet piling is the most reliable, but also the most expensive of the existing methods. Apply the tongue when developing excavations in water-saturated soils near existing buildings and structures. A tongue, metal or wooden, is driven into the ground to a depth exceeding the depth of the future pit by 2 ... 3 m (calculated value), which ensures a stable and natural condition of the soil outside the excavation. Rolled sections (channel, I-beam, pipes) or specially manufactured steel (Fig. 6.9, e) are used as metal racks .

The tongue can be continuous in the form of a single wall, if the tongue is intermittent, then between the posts as the sections of the excavation block a wooden fence, such as shields, individual boards, and bars, are hammered.

Fig. 6.9. Methods of fixing the walls of the grooves:

a - strut; b - anchor; in - console; d-console of bored piles or “walls in the ground”; e - from various types of steel grooves; e - spacer with horizontal shields and prozora; W - cantilever; h - inventory tubular expansion frame; and - inventory fencing shields (zabirka); 1 - stand; 2 - zabirka of boards; 3 - strut; 4 - boss; 5-anker; 6 - delay; 7 - sheet piling; 8 - bored piles; 9 - the same in the casing; 10 - types of the tongue; 11, 13 - spacers; 12 - rack spacer; 14.15 - outer and inner pipes; 16 - coupling coupling; 17 - Vibration shields

The spacer mount is applicable for narrow trenches (Fig. 9.9, g) 2–4 m deep in dry and slightly wet soils and consists of vertical posts, horizontal boards, planks (solid or non-continuous) shields and struts that hold the stands and shields to the walls trench Racks, like struts, are installed along the trench length in 1.5 ... 1.7 m from one another and in height - in 0.6 ... 0.7 m. With coherent pounds of natural moisture and a depth of 3 m horizontal zabirku arrange from boards 5 cm thick with prozory the width of the board, with a greater depth zabirku make a continuous of shields. The spacer mounting is laborious and makes it difficult to work in the trench, especially when laying communications, if conditions allow, then other types of fasteners are used.

Instead of wooden struts and braces, steel tubular struts and telescopic struts are used, the length of which varies due to the rotation of the screw sleeves. These inventory spacing frames are effective due to their low weight, easy installation and disassembly. Metal tubular racks in height have holes for mounting struts. The telescopic strut type (fig. 6.9, h) consists of external and internal pipes, a rotary coupling and supporting parts. Depending on the width of the trench, the distance between the uprights is established by extending the inner tube from the outer one, which is fixed with a bolt-stop inserted into the aligned opening of the tubes. The full pressing of the shields against the walls of the recess is carried out by turning it against the stop of the screw-on coupling.

The main part of the anchor is the expandable element (thrust) made of metal. Anchor thrust is attached to the wall structure with one end, and the other into the earth massif beyond the limits of a possible collapse prism and fixed there with the help of a solution injected into the ground (Fig. 6.9, b). Ground anchor suit as follows.

After the excavation has been developed to a certain point, a well with a diameter of 20 ... 30 cm and a depth of 8 ... 20 m is drilled at an angle to the horizontal, often using casing. Traction is brought into the well, after which the solution is injected into it, monolithing the anchor along the entire length or only in its lower part. When the solution hardens, anchoring. Ground anchors are placed in 3 ... 5 m.

After the excavation has been developed to a certain point, a well with a diameter of 20 ... 30 cm and a depth of 8 ... 20 m is drilled at an angle to the horizontal, often using casing. Traction is brought into the well, after which the solution is injected into it, monolithing the anchor along the entire length or only in its lower part. When the solution hardens, anchoring. Ground anchors are placed in 3 ... 5 m.

Game: Perform tasks and rest cool.6 people play!

Play gameThe simplest and most common anchoring is as follows. At the level of the bottom of the excavation or trench along the walls, they are slaughtered in increments of 1.5 ... 2.0 m (depending on the depth of the excavation and soil moisture) to a depth of 0.5 ... 1.0 m below the level of the bottom of the excavation. These racks are at the level of the top of the pit excavated with anchor rods in the form of two plates, at a distance exceeding the angle of repose and attach these plates to the obliquely clogged anchor. Behind the installed and fixed racks lay shields or plank zabirku. Anchor thrusts are buried somewhat in the ground so that they do not interfere with the movement of people along the curb of the pit.

The strut mount is usually arranged with a fragment of wide trenches with a location inside the pit. Fastening consists of boards or boards, pressed to the ground by racks, fastened with struts with pinching by means of stops. Vertical racks gain stability due to inclined struts and horizontal struts, while the resulting triangle is slip resistant due to the driven inclined anchors in the angle between the struts and the struts. Board boards are installed between the walls of the pit and the uprights, the free distance between them is covered with earth to create a solid, unified structure that will always be stable. This mounting is used sparingly, as the struts and stops located in the pit, complicate the production of basic works.

In process of performance or the termination of works fastening of ditches and trenches assort bottom-up.

List of used sources

1.VSN 5-71 Temporary guidelines for the installation of short bored concrete and concrete piles for low-rise rural buildings

2.Telichenko V.I., Lapidus A.A., Terentyev OM.

Что бы оставить комментарий войдите

Комментарии (0)