Concrete, mosaic and cement-sand floor coverings are used in the lobbies of public and administrative buildings, in the trading floors of shops and catering establishments, in separate premises of industrial enterprises.

Portland cement of high grades, river sand, crushed stone of marble rocks, quartzite, diabase, etc. are used as materials for the installation of such type of coatings. White and broken cement are used for light coatings and pigments are used for color coatings.

Monolithic concrete floors are single-layer with a thickness of 25 ... 50 mm, mosaic and cement-sand - two-layer, the first underlying layer is 25 ... 30 mm, the main covering layer is 15 ... 20 mm.

Immediately before the coating device, the surface of the base is cleaned, richly moisturized and ground with cement milk. For better adhesion, the base of prefabricated reinforced concrete slabs, cement-sand screeds and underlying layers is pre-cleaned of the cement film present on their surface with mechanical steel brushes. Concrete and mortar are laid in a covering with strips up to 3.5 m wide, limited by lighters. Compaction of the mixture is carried out by vibrating rails or areal vibrators. The surface of the coating is smoothed with metal flats, this process must be completed before the concrete and mortar set. The surfaces of concrete and mosaic coatings are sanded by grinding machines when they are coated with a coating of strength, which prevents chipping of coarse filler from the surface. Cement-sand coating is usually smoothed with iron.

The surface of a freshly laid floor is covered with wet sawdust with a layer of 2 ... 3 cm and maintains their humidity for 5 ... 7 days. Baseboards in rooms with concrete, mosaic and cement-sand floors are drawn out with the same solution as the top floor.

The installation of coatings on a soil base . Initially, crushed stone is laid on the ground, rolled with a roller and shed with a liquid solution, getting “thin” concrete. Then the concrete mix is placed in the underlying layer 10 ... 12 cm thick with stripes 3 ... 4 m wide. The stripes are limited to lighthouse boards, concreting is carried out through the strip, the gaps are filled with concrete mix in 24 hours.

There are two solutions to the waterproofing layer, depending on the hydrostatic pressure of water. In the first case, with a slight hydrostatic pressure or in its absence, a cold primer of bitumen diluted in a solvent is arranged on a concrete base, and in the second case, waterproofing is made from rolled materials. The upper protective and supporting coating is carried out in the form of a cement screed or a layer of asphalt concrete.

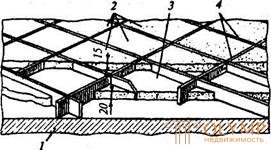

The device mosaic coatings produced in the same sequence as the cement-sand. Decorative, colored varieties of cement are sometimes used as binding materials for such coatings. The peculiarity and complexity of mosaic coatings is the need to use special veins from non-ferrous metal or other material. Veins reduce the possibility of cracking and increase the decorative surface (Fig. 13.1). When constructing a mosaic multicolor coating with veins, the lighthouse and distribution slats are not laid. Veins cut out with a width equal to the thickness of the coating. The mosaic coating is compacted with great care so as not to disturb

Fig. 13.1. Mosaic flooring with streaks: 1 - the underlying base; 2-mosaic cover; 3-veins; 4- screed | pattern. After the final hardening of the solution, the coating is polished until the grains of the filler are exposed, and the scratches and pores are filled with cement pastes. Buildings and structures for industrial purposes, based on the specifics of production, often require special designs of a monolithic floor. At the device of alkali - resistant concrete and cement-sand coatings Portland cement and slag Portland cement are used as binders, as an obligatory additive |

three-calcium aluminate in an amount up to 5% by weight of cement. Spark-free concrete and cement-sand coatings are necessary for explosive production. As fillers for such coatings, coarse and fine fillers are used, made from limestone, marble and other stone materials that do not form sparks when striking various objects about them.

For the manufacture of acid-resistant floor found the use of liquid glass and sodium silicofluoride. Fillers, sand and crushed stone are used only with high acid resistance, in particular crushed stone from diabase, granite and similar natural materials. In coatings of refractory concrete, aggregates (sand and crushed stone) are prepared by grinding chamotte and magnesite materials with high fire resistance.

Metal-cement coatings are used in industries where it is planned to drive on a caterpillar transport workshop or carts on metal wheels. For such coatings of 1: 1 (cement: steel chips), the mixture is usually prepared on alloy steel chips, which are easier to crush. The coating should be double-layered. The bottom layer of cement-sand mortar composition 1: 2 (cement: sand) is laid with a thickness of 15 ... 20 mm, compacted and leveled, but not smoothed. Prior to the cement setting, a layer of metal-cement screed is applied to this layer, which is compacted and smoothed.

Asphalt pavements are used in industries where there is a constant movement of people and vehicles (on rubber tires), in addition, the coating must be insulated from a wet base. The coating is performed on a hot mixture consisting of bitumen, sand and mineral fillers. A well-mixed mixture at a temperature of 160 ... 180 ° C is laid in strips with a width of 1.5 ... 2 m along the lighthouse bars with leveling and compaction with vibratory rollers.

Asphalt pavements are used in industries where there is a constant movement of people and vehicles (on rubber tires), in addition, the coating must be insulated from a wet base. The coating is performed on a hot mixture consisting of bitumen, sand and mineral fillers. A well-mixed mixture at a temperature of 160 ... 180 ° C is laid in strips with a width of 1.5 ... 2 m along the lighthouse bars with leveling and compaction with vibratory rollers.

Xylolite coatings have found application in those industries where warm, non-dusting and sparkless floors are required. The mixture for the device xylolite floor is prepared from caustic magnesite and sawdust in an aqueous solution of magnesium chloride. The xylolite solution is placed in a coating in two layers, pigment is added to the solution for the top layer to tint in the desired color. Sawdust is harvested only from coniferous woods, the size of sawdust for the underlying layer is up to 5 mm, for the main one - not more than 2.5 mm. The mixture for xylolitic coatings is prepared in the work area, as it is active within 1 ... 2 hours. The mixture is laid in strips up to 2 m along the rails with leveling and compaction. It is necessary to proceed to the laying of the upper layer immediately after the lower layer is cured with the obligatory smoothing of the surface with metal trowels. The finished surface is polished, a protective layer of mastic is applied on top.

Polymer-cement concrete coatings are used in premises with increased requirements for cleanliness and dustlessness of the premises, but taking into account the heavy traffic of people and autocars. The mixture for such a coating is prepared on a complex binder - portland cement and plasticized polyvinyl acetate dispersion. The base is coated with a 1: 6 aqueous solution of a polyvinyl acetate dispersion. The finished mixture is laid in strips with compulsory compaction with vibrating rails, after the completion of compaction they are leveled and smoothed with metal trowels. After 2 ... 3 hours after laying the polymer cement concrete cover is covered with sacking or sawdust and moistened during the first 3 days of hardening. The final grinding of the coating is produced by grinding machines, when strength is already gained, at which no aggregate will be crumbled from the coating. On top of the finished coating rubbed with mastics.

Что бы оставить комментарий войдите

Комментарии (0)