Coatings made of piece materials have a very wide range, they are used for flooring in the lobbies of public buildings, shops and other similar rooms and buildings with heavy traffic of people and almost constant wet mode of operation.

The basic properties that any floors of piece and tile materials should have - the strength and durability of the face coating depend primarily on the quality of the preparatory work. Depending on the operating conditions and the purpose of the floors, the following construction processes are assigned to the preparatory - the construction of soil bases, base layers, screeds of the leveling layer, waterproofing, heat and sound insulation layers.

Tiled flooring perform on a rigid base (screed or concrete preparation) or directly on the floor slabs. If the floor of the project should have a slope, then the foundation is prepared with such a slope, but it is not recommended to arrange a slope by changing the slope of the interlayer.

Natural stone coatings are most often arranged in the lobbies of hotels and public buildings, the foyer of theaters and cinemas. For such coatings used rectangular slabs of marble, as well as their waste with a smooth outer surface, obtained by sawing and cutting marble stones, which are called breccia.

Solid marble slabs are laid on the base of a cement-sand mortar. Initially, the plates are laid out at the corners of the room and the thickness of the underlying layer of the mortar is determined, then marble slabs are laid in rows. From breccia, floors are laid with maps from 1 x 1 to 3 mm in two basic ways. In the first case, the lighthouse rows of stones of the correct shape are laid along the axes of the projected map, after sufficient adhesion of the stones with the cement-sand base the card cavity is filled with a solution, into which individual stones are embedded with the selection of marble battle in color and pattern. Freshly laid breccias line up in a map rule.

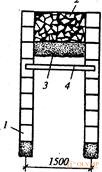

Breccia floors (fig. 13.2). In the absence of stones of the correct form, the marking of the base is carried out with the help of boards or slats, which fix the dimensions of each map. On the solution, breccias are placed in the cards, which are also leveled by the rule. When typing sufficient strength layouts removed, the grooves filled with mortar or special layouts. Maps from the very beginning can be marked with ready layouts, the texture and material of which are specified in the draft. Layouts will be an integral part of the finished breccia coating. Ready-made factory-made slabs of breccia 0.5 x 0.5 m in size and slabs made to specified sizes were used.

Fig. 13.2. The device of monolithic floors from breccia: 1- lighthouse rows of stones of regular shape; 2- stone battle; 3-cement screed; 4-rule |

Fig. 13.3. Laying of ceramic tiles: 1- frieze lighthouse row; 2 - intermediate auxiliary beacons; 3 — reference beacon on the wall; 4- lighthouse rows; 5 - cord-mooring for laying the lighthouse row of tiles |

The floors made of breccia are kept for 3 ... 7 days, then they are polished with a mosaic-polishing machine. First, level the coating, removing possible irregularities with a height of 1 ... 2 mm when grinding dry, then polish and polish the surface with water applied to the floor surface. Polished floors are washed with warm water with the addition of caustic soda.

When arranging tile flooring , facing materials are laid on mortars and mastics, and requirements for the quality of base preparation for floors depend on this.

When a layer of solution gaps between the surface of the preparation and the control rail are allowed no more than 10 mm. If necessary, cut off the protrusions and fill the gaps with the solution. The front surface of floor slabs, screeds and concrete preparation should be cleaned of cement film with mechanical steel brushes, the concrete surface should be cut to a depth of 3 ... 5 mm. Immediately before laying the tiled covering, the prepared base must be primed with cement milk. When laying the surface of the base should be moist, but without accumulation in some separate places of water or cement milk.

Tile coatings on the mastic layer are arranged according to the screed, which is prepared and tested especially carefully. Gaps between the surface should not exceed 2 mm in the preparation of screed for a coating of polyvinyl chloride tiles and linoleum and 4 mm - when coating with other types of tiles. Screed damage and falling irregularities of more than 15 mm are sealed with a cement-sand mortar, pre-cutting down the defective areas and cleaning the surface. Before applying the cover coat, the base is moistened with cement milk.

Often it is necessary to arrange a continuous leveling layer with a thickness of less than 15 mm. Cement-sand mortar for these purposes is not suitable, since such a thin layer quickly loses moisture and as a result does not gain the necessary strength, is destroyed and exfoliated. In such cases, use polymer-cement solution with sufficient water-holding capacity. The base under such a coating is cleaned of debris and pre-ground plasticized emulsion of PVA. The base in the form of a polymer-cement leveling screed is usually arranged under a covering of linoleum, PVC tiles and nap carpets.

Coatings of ceramic tiles (Fig. 13.3) are arranged in rooms with heavy traffic and wet operation. The premises with a systematic or periodic moistening of the floor with water and heavy traffic of people include lobbies, dressing rooms, toilets, showers, bathrooms, etc.

The base under the tile floor is pre-cleaned of dirt and dust, richly moistened with water. Ceramic tiles may be monochromatic, with a symmetrical pattern, the pattern may be abstract. Sizes of ceramic tiles 100x100; 150x150; 200x200 and 250x250 mm, in accordance with the size in terms of change and the thickness of the products. Tiles, pre-sorted by size and moistened with water, are placed on a screed from a cement-sand mortar and on a screed from special formulations specially produced for the installation of a tile floor.

After preparation of the foundation, the whole plane is laid out under the laid floor, the markers are laid out and set up. The lighthouse tiles are fixed, laid against the wall, from which the laying of rows of tiles will begin, friezes, laid along the line of the frieze. In rooms of a large area and at distances between lighthouses of more than 2 m intermediate auxiliary beacons are placed. First, a row of tiles is laid on a layer of cement-sand mortar 10 ... 15 mm thick along the wall opposite to the exit from the room, then two rows along both walls perpendicular to it, then the inner filling is laid. Work must be organized in such a way that workers do not have to stand on freshly laid tiles. The seams between tiles up to 200 mm in size should not exceed 2 mm, for tiles of larger sizes - no more than 3 mm.

After finishing the flooring with plates over the whole area of the working area (2 ... 4 rows of parallel tiles), if necessary, they are upset for alignment. To do this, lay a level or a wooden block 1 ... 2 m long on the surface and use it to hammer tiles along the entire length up to the design level with a hammer blow and simultaneously level the floor surface.

Currently, the domestic market has a wide range of floor and wall ceramic tiles, including porcelain stoneware tiles. This tile of various colors is produced with a different surface (polished, ground, under natural stone) for interior and exterior decorating. Floor tile is durable and low porosity, providing non-staining and high frost resistance. There is a tile that repeats the structure of a parquet of fine wood and unpolished marbled tiles.

For industrial premises, a highly durable technical tile with dimensions ranging from 15x15 to 60x90 cm) with a ribbed surface to ensure anti-skid is produced. For medical institutions are used antistatic stoneware, tiles, absorbing X-rays, special rough and non-slip tiles for finishing the surface of pools.

If necessary, create a slope of the floor on the ceilings under the waterproofing layer provide for the installation of a screed of concrete not lower than B15 with a corresponding slope of its surface. The smallest thickness of this screed in the places of junction with the drain bridges when it is laid directly on the floor slab should be 20 mm, and when laid on the heat or sound insulation layer - 40 mm

Small-sized mosaic ceramic tiles are produced in sizes 23x23 and 23x48 with a thickness of 6 ... 7 mm. The specificity of the tiles is that in the factory, the tiles are glued onto the square sheets of thick paper-card. Laying of such ready-made maps is carried out on a cement-sand mortar with a layer thickness of 15 mm. After the base has been prepared and the markup is tensioned, the mooring cords along the seam line between the cards. The sequence of laying is from the far wall to the door, the cards are laid out with paper upwards, blown with a hammer on a wooden bar to be leveled in order to align and ensure the grout is filled with joints between tiles. Between the cards arrange seams 2 mm wide. After laying the cards, the floor surface is covered with wet sawdust and kept. After 2 ... 3 days. paper is washed off with warm water, the tiles are cleaned with hard brushes, the seams between the tiles are filled with a liquid cement-sand mortar, after which the floor surface is wiped with wet sawdust.

Sometimes in the tiled floors of large rooms some time after the start of operation, cracks appear in the form of transverse lines. The reason for such a defect can be the laying of coatings without the device of expansion joints under the temperature joints or the wrong connection to them. Sometimes a tile exfoliates from the preparation along with the grout; this may be due to shocks and deformations of the base structure itself. To prevent or reduce such a defect, the tile on the solution is placed on a sand pad of wet sand 4 ... 5 mm thick with a small amount of cement added to its surface (1 ... 2%). This layer of sand significantly reduces the effect of deformations of the overlap on the tile floor, in addition to this, wet sand prevents the concrete from over-stretching water from the cement-sand mortar on which the tile is laid.

The reason for the detachment of tiles can be the use of fat solutions, solutions that have already begun to set, laying dusty, dirty and tiles with fat and tar stains.

Tiled floors, laid on concrete preparation on the ground, can be destroyed by precipitation and swelling of the soil. Sludge may be due to the presence of bulk soil, the compaction process has not yet ended. Concrete preparation can swell from wetting and heaving of underlying soils and foundation. The integrity of the tile coating can be compromised when laying the mortar on a dry, wet concrete preparation. Dry concrete quickly absorbs moisture from a thin layer of mortar, due to which the interlayer solution is dehydrated, does not acquire sufficient strength when cured, which leads to delamination of the tile coating.

Under the action of sunlight the solution of the cement-sand layer of the freshly-made floor is greatly weakened if it is not kept wet. The strength of the floor on acid-resistant solutions with the use of liquid glass, on the contrary, is markedly reduced if, after installation, the coating is not maintained in dry conditions and is not protected from ingress of water, acid solutions.

To identify the area of necessary repairs, first of all, we determine the backward tiles by knocking the entire floor area. Then dismantle the place to be repaired, but only if it can be done without damaging the tiles. If necessary, defective places break open, i.e. knock the tiles along with the solution. First, the first tile is broken into pieces, then the adjacent tiles are removed with a chisel or skarpel in order to be able to reuse them. Then a chisel or other tool, electric or pneumatic, is cut down and removed the cement layer to the surface of the base,  which is leveled with concrete or mortar. If necessary, restore the impaired waterproofing, then on the repaired area re-lay the tile floor.

which is leveled with concrete or mortar. If necessary, restore the impaired waterproofing, then on the repaired area re-lay the tile floor.

Что бы оставить комментарий войдите

Комментарии (0)