Quality management (QM) of products is understood to mean the establishment, provision and maintenance of the required product quality during its development, operation or consumption. It is carried out through systematic quality control and targeted impact on the conditions and factors affecting product quality.

Two ways to improve the quality of buildings and structures:

1. consumer - installation of new increased regulatory requirements, development of progressive design solutions, production of efficient building materials and products;

2. production - unconditional support of the requirements of regulatory project documentation during the manufacture of products, production and installation works, as well as in the development of projects.

Production quality is directly related to four areas of activity:

1. design;

2. manufacture of building materials, structures, parts;

3. production of SMR;

4. operation.

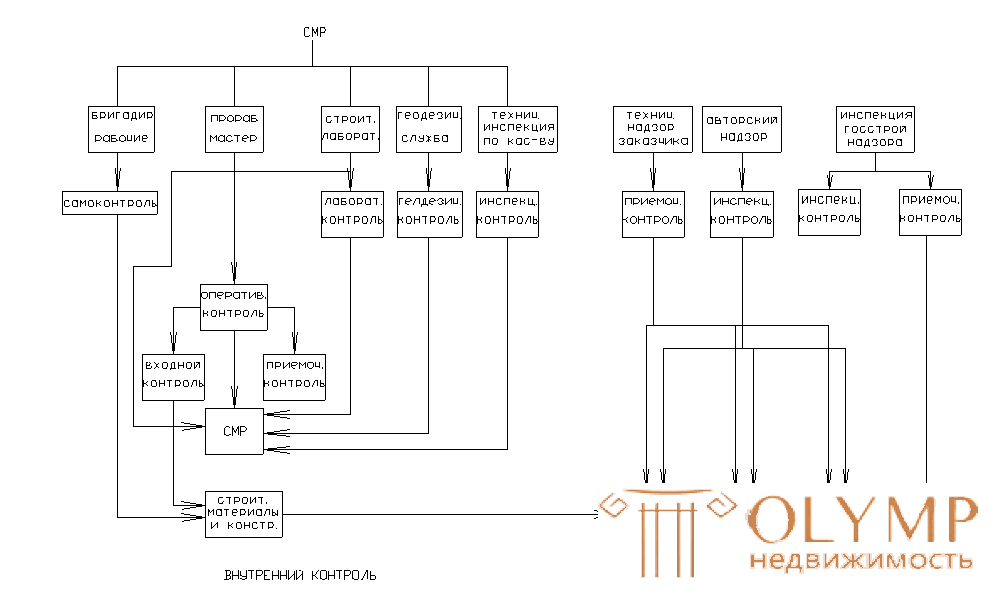

Quality control organization :

Quality control design is carried out:

a) internal control - self-check, second verifier, check by the leading group, department, chief specialist, GIP or GAP, chief engineer of the institute;

b) external control - customer's control, control by coordinating organizations, control by general contracting and subcontracting organizations, expert appraisal of design and estimate documentation, environmental impact assessment, Ministry of Emergency Situations.

Quality control of materials, structures, semi-finished products:

a) internal control - self-test, factory laboratories, Quality Control Department

b) external control - Rosstandart, construction laboratories, sanitary and epidemiological supervision, state construction.

The quality control of SMR is as follows:

Что бы оставить комментарий войдите

Комментарии (0)