The laying of arches (including arched lintels in the walls) and arches must be made of bricks or stones of the correct form on a cement or mixed mortar.

For masonry arches, arches and their feet should be applied mortars on Portland cement. The use of slag Portland cement and pozzolanic Portland cement, as well as other types of cements that slowly harden at low positive temperatures, is not allowed.

Deviations of the formwork of the double curvature vaults from the design should not exceed: the lifting boom at any point of the arch is 1/200 of the ascent, the formwork is offset from the vertical plane in the middle section of the arbor 1/200, 10 mm.

The laying of the waves of vaults of double curvature must be carried out using movable templates mounted on the formwork.

Laying arches and vaults should be made from the heels to the castle simultaneously on both sides. Laying seams must be completely filled with mortar. The upper surface of the arches of double curvature with a thickness of 1/4 of the brick in the process of laying should be rubbed with mortar. With a greater thickness of the vaults of bricks or stones, the masonry joints must be additionally filled with a liquid solution, while grouting with the top surface of the vaults is not performed.

The laying of double curvature vaults should begin no earlier than 7 days after the end of the device of their toes at an outdoor temperature above 10 ° C. When the air temperature is from 10 to 5 ° C, this period is increased by 1.5 times, from 5 to 1 ° C - by 2 times.

The laying of arches with puffs, in the heels of which prefabricated reinforced concrete elements or steel frames are installed, may be started immediately after the end of the device of the heels.

The edges of adjoining adjacent waves of double curvature arches are kept on the formwork for at least 12 hours at an outdoor temperature above 10 ° C. At lower positive temperatures, the duration of keeping the arches on the formwork increases in accordance with the instructions of SNiP 3.03.01-87.

Loading of decomposed arches and vaults at air temperature above 10 ° С is allowed no earlier than 7 days after the end of laying. At lower positive temperatures, aging periods increase according to SNiP 3.03.01-87

Insulation on the arches should be laid symmetrically from the supports to the castle, avoiding a one-sided load of the arches.

Tension pulls in the arches and arches should be made immediately after the laying.

The construction of arches, vaults and their soles in winter conditions is allowed at an average daily temperature not lower than minus 15 ° С on solutions with antifreeze additives. The waves of the arches, erected at a negative temperature, are kept in the formwork for at least 3 days.

In modern standard construction of bridges made of brick, this is perhaps an outdated technology. However, if you decide to build a small palace (or a large castle) with arches and arches, then this article will be useful to you.

Lintels - structural elements that overlap the window or door openings. The width of the opening, overlaid by a jumper, is called a span. Most often, the openings overlap with prefabricated reinforced concrete bar and slab bridges of factory manufacture. Sometimes the openings are covered with brick structures: ordinary, blade-like, arched and arched lintels. Ordinary lintels are rows of masonry reinforced with reinforcement at the bottom. The laying of such jumpers are as follows. A form of a mortar (composition 1: 3) 2 cm thick is laid on the formwork, reinforcement is laid from four rods with a diameter of 5 ... 6 mm (with a wall thickness of 2 or 2.5 bricks); the bent ends of the reinforcement are laid in a stack of 250 mm on each side. The laid reinforcement must be covered with mortar on all sides.

Ordinary jumpers with a span of 1 to 2 m spread on mixed solutions of brand 25 and above.

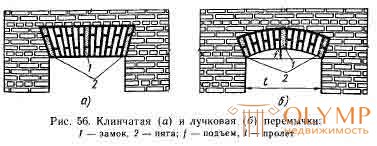

Wedge lintels (Fig. 56, a) are laid out of bricks laid on the edge. In such bridges, a brick located in the center is called lock 1, and supports are fifth . 2.

The beam segment jumpers (Fig. 56, b), in contrast to the blade jumpers, have a rise f (height from the bottom of the castle to the bottom of the toes), which is expressed in fractions of the span, for example, 1/10, 1/12.

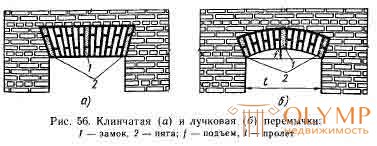

If the radius with which the jumper is drawn approaches in size to half the span of the jumper, then this jumper is called an arch.

Semicircular arched bridges (arches ) (Fig. 57a) have the shape of a semicircle (their supporting heels are located at an angle of 30 ° to the horizon); duct arches (fig. 57, b) are more gentle, with the boom of lifting f less than half of the span. Limit spans arches up to 4.5 m.

Laying arches, v-shaped and ordinary jumpers are using formwork. For ordinary and blade lintels used timber metal formwork - shields 40 mm thick. With a span of up to 1.5 m, the formwork is supported on releases of masonry 6 cm long from two rows of bricks, which are cut down after the removal of the formwork. In spans of more than 1.5 m, the formwork shield is supported on wooden stands.

Laying arches lead on circles cut from boards having the shape of the lower outline of the arch. Circled up make up of separate jambs, shot down in two layers with the break-up of the joints. On top of the circle the formwork is sewn on with nails, on which the masonry is laid.

The laying of the web-like lintels starts from the heels to the middle and ends with a lock; The number of bricks to be stacked must be odd. The thickness of the vertical seams at the top of the lintel is up to 25 mm, at the bottom - not less than 5 mm. The limiting span of the web lintels is up to 2 m.

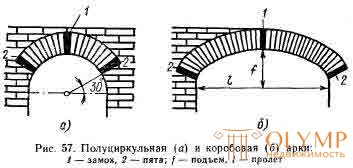

Timing strips jumpers are given in Table. 45.

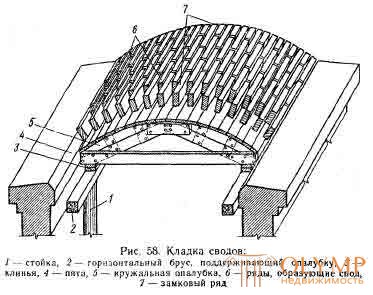

With arches, in contrast to arches, they block not separate openings, but entire rooms. The most common cylindrical arches, based on two parallel walls. Vaults spread out of brick on formwork 5 (Fig. 58) with a solid plank flooring. The laying is carried out in separate sections, simultaneously from the heels to the top. The radial position of the seams is controlled by a gon. The laying of the site ends with the arch blocking the castle with bricks. It is forbidden to walk and store materials on the laid part of the arch. The dismantling of the arch is carried out in 10 ... 20 days.

Arches and vaults transmit a horizontal load to the supports, called thrust. If the size of the thrust is significant, then install steel inhaling, anchored in the supports.

For the laying of smoke channels and pipes, only ceramic bricks of the correct form, normal firing, without cracks are used. The quality of a brick is determined by lightly tapping a hammer (it should not ring) and in appearance. The first two rows of chimneys are laid out, as in the case of a single-row dressing system, followed by bricks laid with spoons. To ensure ligation apply incomplete brick. Dimensions of chimneys 140x140 and 140x270 mm. They are arranged vertically and separated from each other by cuts into 1/2 brick. Chimneys inside the building have the appearance of separate risers or they are placed in the inner stone walls. Between the smoke channels have ventilation channels to improve the circulation of heated air. They can also be made of silicate brick.

Chimneys in one-story buildings are laid out on clay mud, with a height of more than one floor, on lime-sand or lime-cement-sand solution. Sifted sand is used for the clay mud solution, since the greatest strength of the masonry is ensured with a weld thickness of not more than 5 mm.

The thickness of the seams of laying pipes on lime or complex mortar is not more than 10 mm. Laying on the clay mud solution is performed, completely filling the seams. Every four to five rows of laying with a wet brush or cloth, remove the excess solution in the joints. It is not allowed to lay the brick with the cut side inside the channels or to level the internal surfaces of the channels with mortar. Smoke ducts are separated from combustible structures by air gaps or insulated with non-combustible materials.

Chimneys within the attic or above the roof spread on lime or complex solutions. Within the attic they are plastered.

Round and rectangular wells for plumbing and sanitary - structures built of brick. For water supply network of pipes with a diameter of 50 ... 600 mm, round wells are used with a height of the working part of 1.8 ... 3.3 m, a diameter of 1 ... 2 m, as well as rectangular wells with a height of the working part of 1.8. ..3.9 m and dimensions in the plan from 2X2.5 to 3X3 m. The depth of the wells is 2.5 ... 4 m. The thickness of the brick walls depends on the depth of the ground and the soil conditions and lies within 12 ... 77 cm . For the sewer network of pipes with a diameter of 150..1200 mm, round wells are used with a lower diameter of 1 ... 2 m and the upper one - 0.7 ... 1 m. The height of the working part is 0.9 ... 2.7 m, height tapering cone neck - 0.65 ... 4 m. For laying sewer wells used ceramic bricks and cement-lime or cement mortar.

Prior to the laying of the well, a concrete basement of 10 ... 15 cm thick is arranged on the compacted soil. After laying and hardening the concrete mix, the well is laid out on the base: for a round well, its center and inner circumference are marked, for the rectangular well and outer edges of the walls. Then the brick is made and laid out, the mortar is spread out and the brick is laid in the usual sequence.

Round wells lay tychkovymi rows. The bricks are arranged so that their knurled faces form the inner surface of a well of a given diameter. Laying the masonry is done by offset bricks in the adjacent rows by a quarter of the brick. Vertical seams on the inner surface of the masonry should be completely filled with mortar. Significantly widened seams on the outside of the masonry should also be well filled, especially when constructing wells in moist soils.

Что бы оставить комментарий войдите

Комментарии (0)