When maintaining masonry it is necessary to monitor the horizontal position and the thickness of the seams, the verticalness of the planes and the correctness of the corners. The correctness of the corner is checked with a square, the verticality of the surfaces is a plumb, it is done at least two

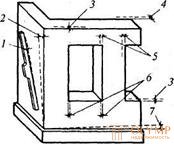

Fig. 13.4. Masonry tolerances: 1 - vertical surface - 10 mm; 2 –surface angles per floor - 15 mm, the entire height of the wall -30 mm; 3 - cutting marks - 10 mm; 4 - masonry thickness ± 15 mm; 5, 6 - width of walls and openings ± 15 mm; 7 - masonry rows from horizontal to 10 m length - 15 mm | times per meter of masonry height. Horizontal masonry check level and rule. Checking the horizontal masonry also produce at least two times per meter height. The thickness of the seams is controlled with a steel ruler or meter in 5 ... 6 rows of masonry. Permissible deviations of surfaces and angles (Fig. 13.4): - from vertical to one floor - 10 mm, to the entire height of the building - not more than 30 mm; - from the horizontal to 10 m of the laying length - not more than 15 mm. In addition, check the quality of the seams, the thickness of the seams, the correctness of the laying and the amount of support on the laying of reinforced concrete elements. For winter masonry are logging works, |

in which they fix the temperature of the air and the solution at the moment of its laying, the temperature of the brick during artificial heating, the state of the brick during the thawing period.

Before the beginning of the brickwork, on the border of the plots retracted to the individual links of the bricklayers, and on the corners of the walls, rails are installed, divided into divisions according to the rows of masonry. To create and maintain the straightness and thickness of the masonry rows, apply a stretched cord-mooring, the vertical direction of the masonry is checked by a plumb.

Should be clearly delineated duties between the bricklayer and ancillary. Maintenance worker lays out the brick on the wall and spreads the mortar. For laying the outer row, the brick is laid out closer to the inner row, for laying the inner row - on the outer row or closer to it. Depending on the solutions used, the plasticizers used, the mobility of the solution, decide on the method of laying bricks - priprytyk (vpustoshovka) or priprizhim.

It is desirable to have a clear distribution of responsibilities in the integrated installation team that builds a brick house: laying brick, blocks on mortar - bricklayers; installation of prefabricated structures - installers; scaffolding or scaffolding - carpenters or installers; delivery of materials to the workplace - transport workers.

For the implementation of quality control and productivity of workers use the basic regulatory data: brick consumption per 1 m of masonry about 400 pieces, a solution of 0.24 m3; labor costs per 1 m3 of laying from 0.77 to 2 persons / day;

average output per worker per shift 0.8 ... 1.1 m3.

Actual performance per worker per shift:

working "loner" - 300 ... 500 pcs. brick or 0.7 ... 1.2 m3

masonry;

worker in the level of "two" - about 1000 pcs. brick or 2.5 m3;

in the “five” link - 1700 ... 2000 pcs. brick or 4.2 ... 5.0 m3.

When performing laying in winter conditions and exercising quality control of the work performed, the SNiP 3.03.01-87 should be guided.

Что бы оставить комментарий войдите

Комментарии (0)