Plasterboard has long been used for interior decoration during repairs. It has many advantages that made it so popular. However, its sound insulation properties leave much to be desired. Therefore, during repairs, they often resort to the use of special sound-proof materials, which are installed in a metal frame, to which GCRs are attached. But what if you can not do this?

There is a special acoustic drywall on the building materials market that can be installed without additional noise insulation. Consider what this material is and if it makes sense to use it.

Content: [hide]

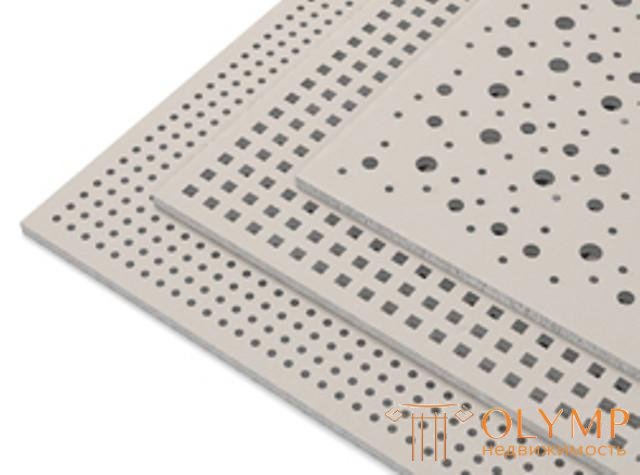

The entire surface of the acoustic drywall is covered with through holes

A new type of drywall sheets appeared not so long ago to become popular. This product was designed specifically for use in areas where there are increased requirements for sound insulation. However, it can be used within your apartment so as not to conflict with your neighbors due to excessive noise.

Soundproof plasterboard gets its properties due to the following technical solutions.

In combination, both of these factors helped transform an ordinary plasterboard into a real soundproof material.

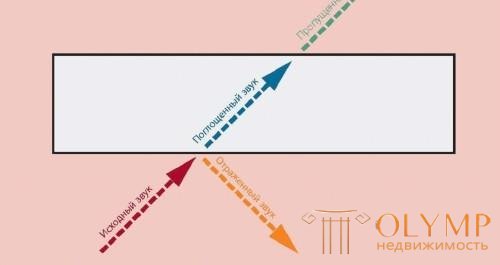

Due to the perforation, many through holes play the role of resonators. Instead of sound waves reflected from a flat surface, they fall into holes, where they fade.

Perforated drywall has several advantages:

Not everyone will like this ceiling in the living room.

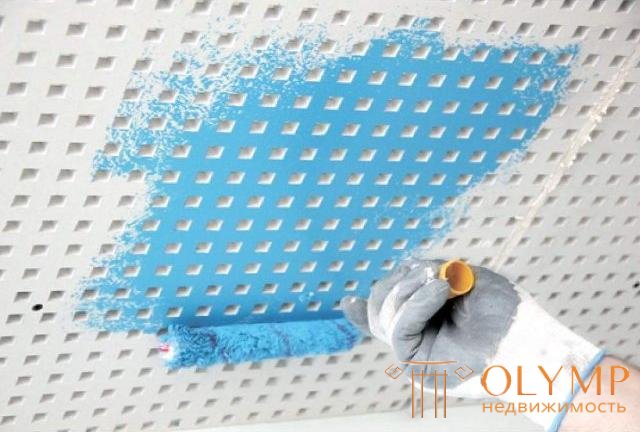

This material has one very significant drawback. We are talking about the very perforations that are not going anywhere. Sheets can be neatly dyed, but that's all. No plaster or wallpaper on soundproof drywall can not be applied. If you close the perforation, the material will lose its properties. So its appearance does not change . Even careless painting can lead to deterioration of sound-proofing characteristics.

The holes themselves inside the paint will not work

Few people want to live in an apartment where there are holes in the walls. For the ceiling, this option is still suitable, especially if you correctly make the backlight. But even in this case, not everyone wants to live in a room with a ceiling full of holes. For this reason, perforated drywall is more often used in such non-residential premises:

From the foregoing, it can be concluded that in everyday maintenance, acoustic GCR is used extremely rarely.

The three main types of perforated GCR

Acoustic drywall comes with perforations of different shapes.

Different forms of perforation are chosen for both design and selection of the required absorption characteristics of sound waves for specific conditions. In most cases, the holes are distributed evenly throughout the sheet. The block version (when the perforation is performed in blocks) is much less common.

Sound absorption of the material in the range of 500-2000 Hz is 85% (the sound wave is absorbed by 85%). The average sound absorption index is 55%, and for sheets with chaotic perforation it is 45%.

The principle of reflection and absorption of sound waves

The edge of the sheets of soundproof plasterboard can be straight and folded. And the edge is not necessarily the same from all sides, from two sides it can be figured, and from two sides it can be curved. When mounting the sheets, they should all be the same.

Standard sizes are as follows:

Depending on the size of the sheet, its weight ranges from 8.8 to 9.6 kg, and its density reaches 650-730 kg / m3.

Installation of perforated plasterboard is almost the same as in the case of conventional gypsum board. Depending on the situation, a frame is created, which is then sheathed with sheets.

Due to the perforation sheets have less weight, which simplifies working with them. They are also easy to cut to the desired size, but not bend.

Screws are screwed in the center between the available holes.

It is necessary to fix sheets to the frame with the help of all the same screws. They can be screwed into existing holes, but this method of fastening is not considered very reliable. Therefore, use special bushings and even dowels. You can go along the standard path and attach the material by scrolling the screw through the entire thickness of the sheet. In this case, you need to be careful, because the screw will have to be inserted between the perforations.

Acoustic drywall may not be the most suitable solution for sound insulation inside an apartment, but for non-residential premises it is ideal.

Что бы оставить комментарий войдите

Комментарии (0)