The erection of buildings from small-sized elements requires a lot of labor, does not allow the extensive use of automation and mechanization of construction. One of the ways to increase the degree of industrialization of the construction industry is the design and construction of buildings from large blocks. Comparison of technical and economic indicators of brick and large-block buildings shows that construction time is reduced by almost 15, and labor costs - by 20%.

Large blocks are buildings whose walls are made of large stones (blocks) weighing from 0.3 to 3.0 tons or more. In these buildings, all other structural elements are also made of large-sized elements and parts.

Large buildings

Constructions of large-block buildings are full-assembly. External and internal walls are mounted from prefabricated prefabricated structures weighing up to 5 tons.

For buildings up to 5 floors, a frameless, constructive system with longitudinal bearing walls is used, and for buildings of a higher number of floors - with large or mixed pitch of transverse walls.

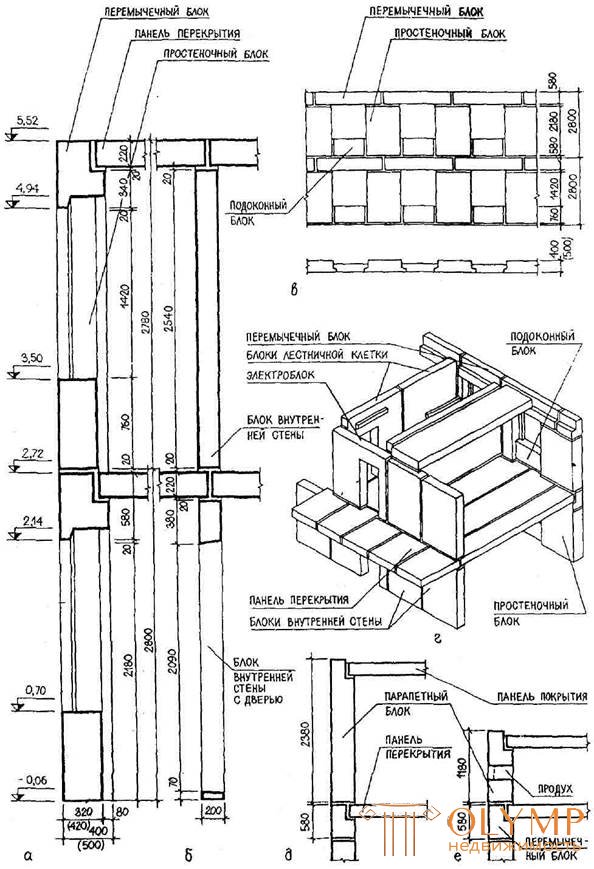

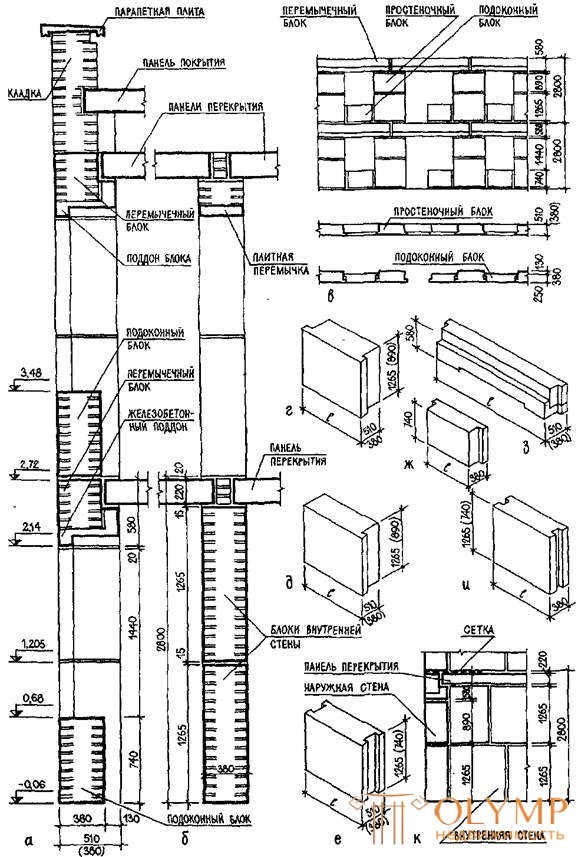

The outer walls within the height of each floor are divided horizontally into two, three or four rows of blocks.

Most often, two-row cutting is used for housing construction (Fig. 118.).

Large blocks of external walls are made of lightweight concrete brands M-50, M-75, M-100 with a density of no more than 1600 kg / m3, and blocks of the internal walls are made of heavy concrete brands M-150 and M-200.

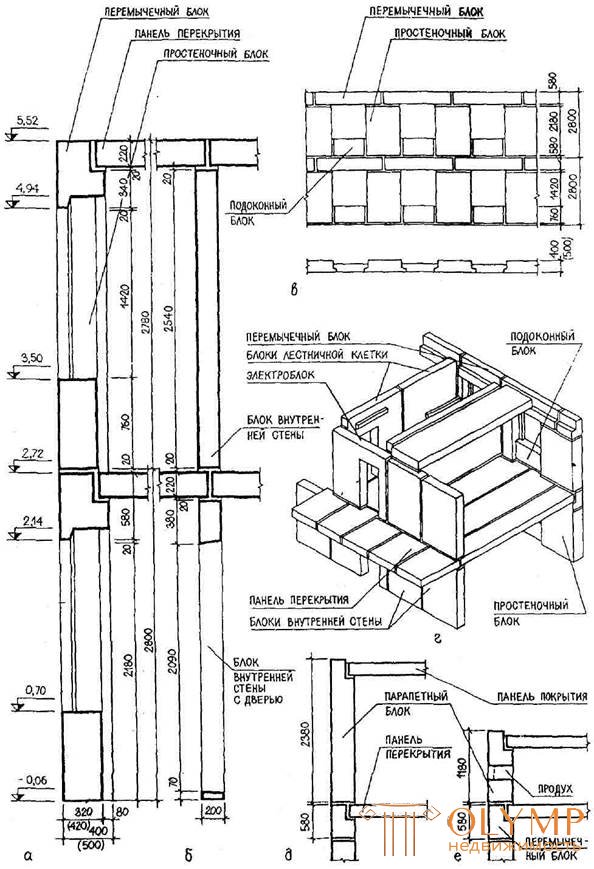

Large blocks of external walls are divided into prostanochnye (ordinary, angular, additional); lap (ordinary, angular, additional); jumper , window sill, basement (ordinary, corner, additional); parapet, eaves (fig. 119.).

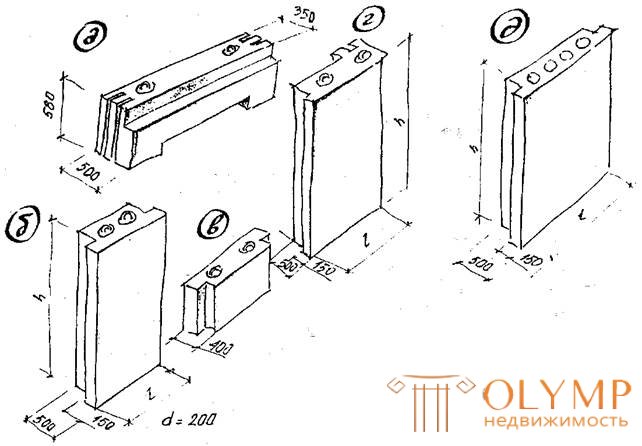

Horizontal and vertical joints of blocks of external walls in the seams of the cut from the outside seal. In the vertical joints install insulated liners (Fig. 120.).

Large blocks of internal walls are divided into wall, ventilation and special: electrical blocks, blocks of staircases, attic, etc. These blocks within the floor can have single-row and two-row cutting. The most common single-row cutting.

Durability and stability is provided:

- selection of the appropriate brands for compressive strength;

- laying walls on the solution with ligation of vertical joints;

- monolithing vertical joints between blocks with lightweight concrete

M-75 and M-100 brands;

- steel connections between blocks of external and internal walls;

- based on the overlap of the floors on the layer of cement - sand mortar and the steel connections of the belt and bridge blocks with floorings of floors and coatings.

Brick blocks up to 1m3, i.e. weighing up to 3 tons, are made in advance at a brick factory and, rarely, at a construction site.

For the manufacture of brick blocks used lightweight brick (perforated, slotted). The bridging block has a complex construction with a reinforced concrete slab below (121.).

DETAILS OF WALLS OF LARGE CONCRETE BLOCKS

a - ordering the outer wall; b - ordering of the inner wall; in - cutting the outer wall; (d) structural diagram of a fragment of a large block building;

Fig. 118.

MAIN TYPES OF LARGE BLOCKS OF WALLS OF RESIDENTIAL BUILDINGS

a - block external wall; b - the same, patented; in - the same subwindow;

g - angular; d - wall with round voids

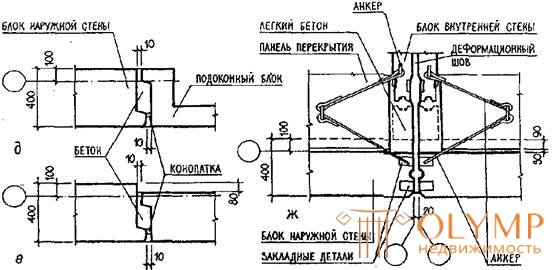

DETAILS OF STRETCHING BELLETREEN WALLS

a - closed joint of blocks of internal walls or block - lintel of external walls; b - closed joint of the wall and window blocks; в - open joint of the wall blocks of external walls; d - connection of the jumpers of the external wall blocks

Fig. 119.

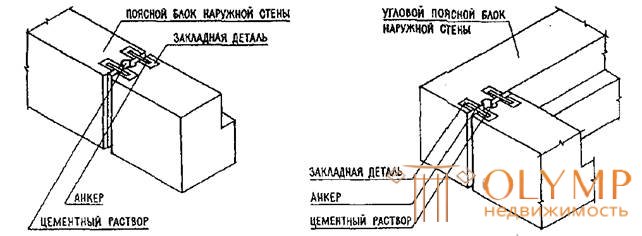

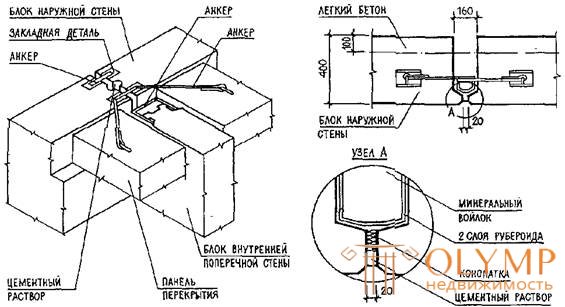

DETAILS OF WALLS FROM LIGHT-CONCRETE BLOCKS

CONNECTION OF THE BREADDING AND BELTED BLOCKS OF EXTERNAL WALLS

CONNECTION OF ANGULAR BLOCKS OF EXTERNAL WALLS

COUPLING OF THE INTERNAL WALL BLOCK TO THE EXTERNAL WALL BLOCKS

CONNECTION OF EXTENSION WALLS EXTERNAL WALL

CONNECTION OF SOCKET BLOCKS TO THE SPRING WITH A COLD CABINET UNDER THE WINDOW AND NORMAL

EXPANSION JOINT

Fig. 120

MAIN LARGE BRICK BLOCKS AND WALL PARTS FROM THEM

a, b - ordering of the outer and inner walls; in - cutting the outer wall of large brick blocks; g - wall block; d - corner block of the outer wall; e - end wall block; W - subwindow unit; h - jumper block; and block the inner wall; K - vertical section of the outer wall and adjoining the inner wall to it

Fig.121.

Что бы оставить комментарий войдите

Комментарии (0)