Large-panel buildings

The goal of industrialization is to reduce the time and cost of construction, improve the quality of work and increase productivity.

The main focus in the design of residential buildings is to achieve maximum assembly. The degree of assembly and economic efficiency of residential buildings depends primarily on the design decisions taken.

Buildings whose walls and partitions of large elements of relatively small thickness are called large-panel .

The construction of such buildings marked the transition from semi-handmade to industrial industrial construction methods.

The advantages of large-panel construction :

1. High degree of industrialization of construction with a mounting crane of finished elements weighing 3 or more tons;

2. Reduced construction time (2-3 months);

3. Decrease in labor input on installation in comparison with brick in 2 times;

4. Reducing the weight of structures by 2.5-3 times;

5. Reducing the cost of construction.

Principles for the solution of external building envelope:

1. The principle of combining enclosing, insulating and supporting functions of external enclosing structures in one structural layer and the formation of a homogeneous (single-layer) structure.

2. The principle of separation of enclosing, insulating and supporting functions of external structures between the individual layers and the formation of a heterogeneous or layered structure.

Panels of internal walls are usually single-layer (Fig. 123.).

Efficient modern insulation materials

The weight of the panels is reduced due to effective insulation:

(λ is the coefficient of thermal conductivity of the material in kcal / m h degree

Foam concrete

γоб = 300-500 kg / cm2; λ = 0.11- 0.15 - insulation; γob = 800-1000 (carrying)

Mineral wool boards (semi-rigid)

γob = 300-350kg / cm2; λ = 0.08 - 0.1

Produces Zaporozhye slag-cotton mill;

Foamglass - is obtained from glass sand with the addition of blowing agents. Very effective material, differs in firmness from atmospheric actions.

γob = 300-400kg / m3; λ = 0. 11 - 0.14

Foam foam - obtained from lightly fused clays during firing with the addition of blowing agents

γob = 350-500kg / m3; λ = 11-0.17; "M" = 10.40.50

Expanded clay - is obtained from clay during firing and expansion without additives. γob = 500-900kg / m3; λ = 0.18-0.35

Permet

γob = 150-300kg / m3

Thermozite concrete (heat resistant construction)

γоб = 800-1400 kg / m3; λ = 25-0,60

Keramzytobeton

γоб = 700-1400 kg / m3; λ = 0,2-0,5

Permetobeton

γob = 300-500kg / m3; λ = 0.11-0.14

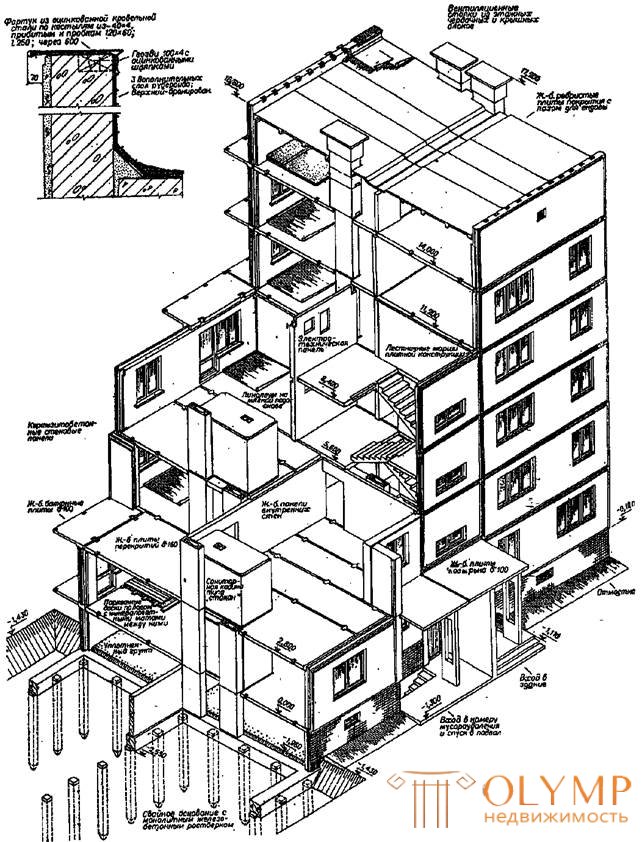

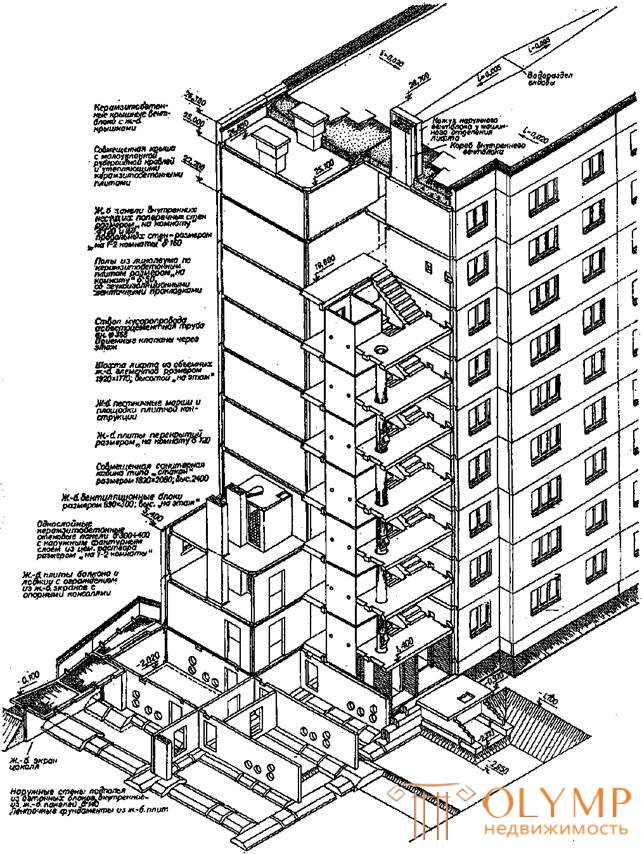

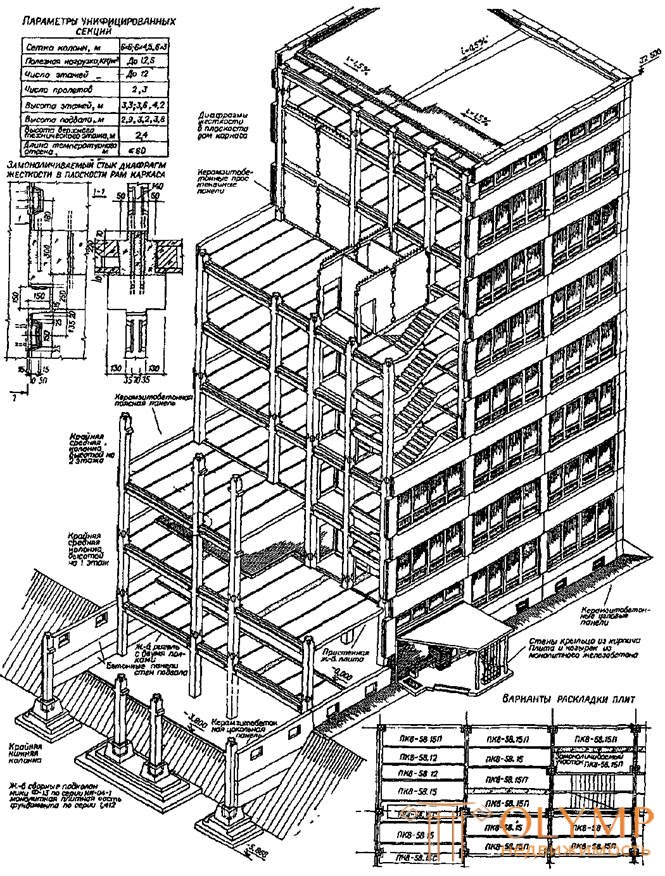

Structural schemes of large-panel frameless buildings:

a) with bearing external walls and internal transverse and longitudinal partitions;

b) with three bearing longitudinal walls;

c) with transverse bearing partitions working in compression.

Structural schemes of large-panel frame buildings:

a) with a full transverse frame;

b) with a full longitudinal frame;

c) with a spatial frame;

d) with an incomplete internal frame and bearing panels of external walls.

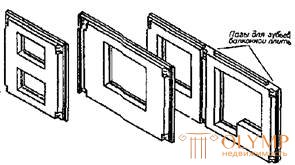

The partitioning schemes for exterior walls on the panel

Choosing the scheme of cutting the building on the panel it is necessary to provide the minimum number of standard sizes of mounting elements with their maximum coarsening. Preferences should be given to the pattern of cutting walls, in which the length of the seams will be the smallest (Fig. 122, 123, 124, 125, 126, 127, 128, 129.).

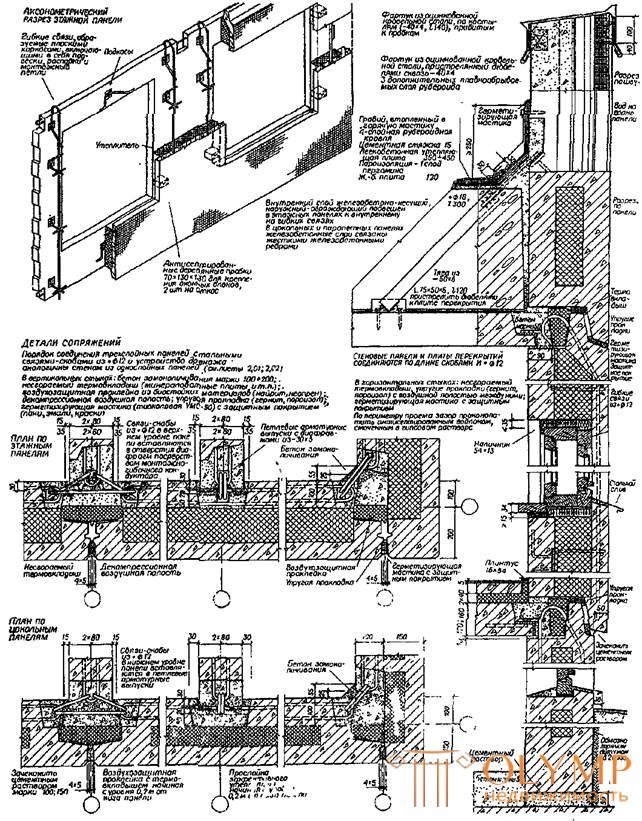

Constructions and interfaces of large-panel building elements

In addition to the general requirements for external walls (strength, stability, low thermal conductivity, frost resistance, fire resistance, low weight, cost-effectiveness), the exterior wall panel design should provide simplicity of factory technology and its manufacture, perfect joint design, high degree of factory readiness. The form and decoration of the panels must comply with the architectural requirements for this type of building.

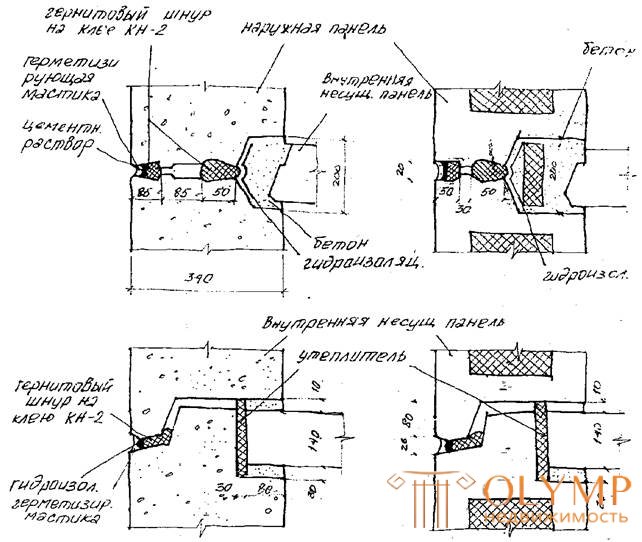

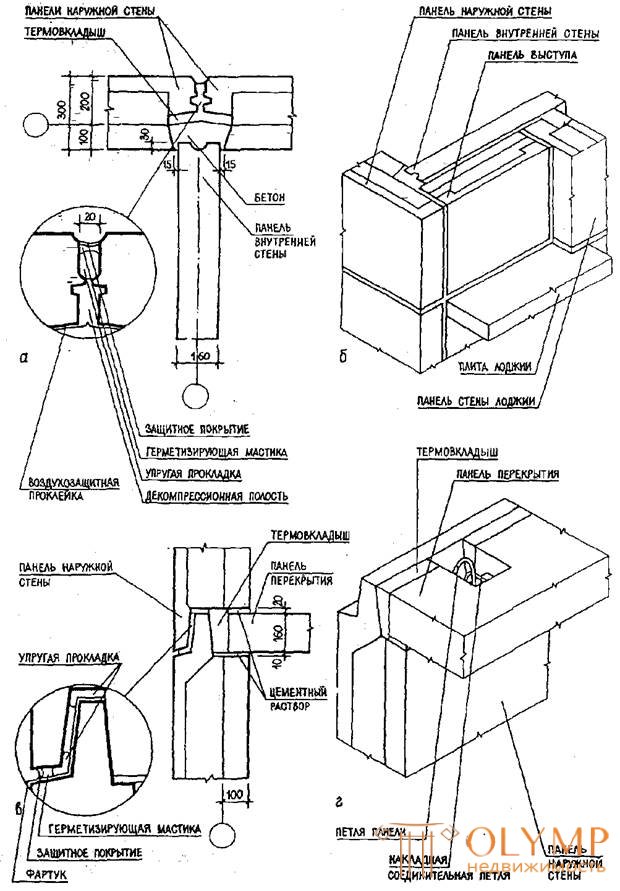

The performance of panel houses largely depends on the design of the joints between the panels. The main requirements for the joints of large-panel exterior walls are tightness, as well as the impossibility of the formation of condensate at the junction in winter. In addition, in the load-bearing and self-supporting panels, the design of the vertical joint must reliably perceive tensile, compressive, and sometimes transverse forces to prevent the joint from cracking (Fig. 130, 133, 134, 135, 138, 139.).

The most important places are the joints of the external panels with each other and with overlap.

Requirements: strength, durability, ease of installation, heat insulation and sealing.

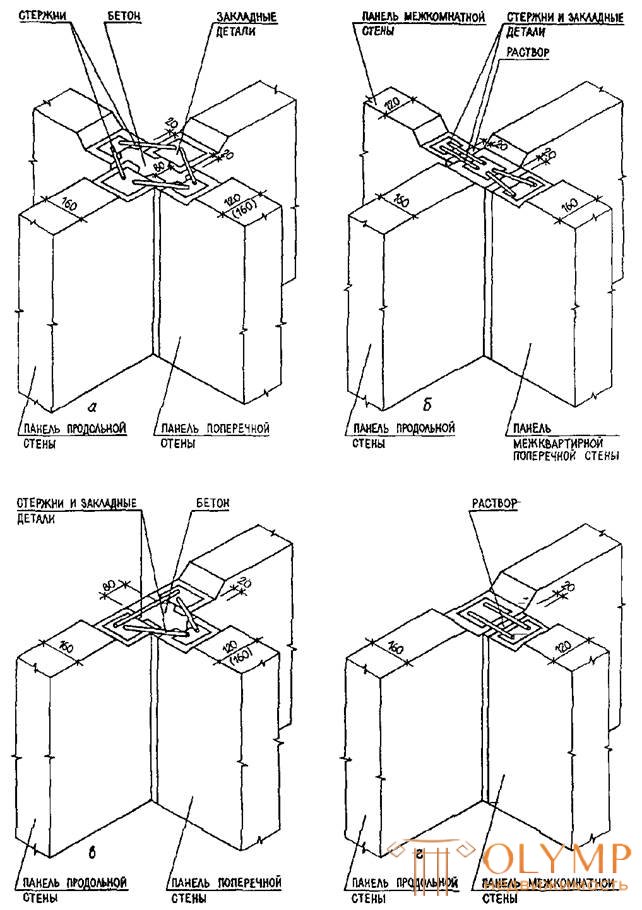

By the method of connection: welding; on loops; on the bolts (Fig. 132, 134, 135, 140).

There are monolithic with filling the joint cavity with concrete or mortar, i.e. performance in the wet way (bearing and self-supporting);

Dry, which do not require the execution of wet processes at the work site, with the exception of caulking seams with cement mortar (hinged panels).

Dry joints - filled with elastic insulating material that perceives deformation without cracking and has compensatory properties, i.e. the ability to tightly fill the joint, regardless of the narrowing or expansion of the seam (black sealant UM-30, sealing mastic UM-40 - experimental character).

Semi-dry, in which part of the cavity is filled with a dry liner of effective insulation, and the other part - with heavy concrete.

The strength and durability of large-panel houses largely depends on the durability of the metal bonds between the main structures of buildings. Therefore, the protection of steel parts from corrosion is one of the most important tasks of large-panel construction.

Anticorrosion coating - parts are factory coated on all sides with zinc by sputtering, hot-dip galvanizing or galvanizing. The subsequent protection of galvanized steel elements1 is carried out by their monolithing with a cement-sand mortar (1: 1.5-1: 2) with a thickness of at least 20 mm.

Ceramic tile, glass mosaic, various stone textures are widely used for facing exterior panels

Fastening of facing materials - thin-cut stone (thickness 10 mm), ceramic and glass tiles - to expanded clay concrete is carried out without the use of fasteners due to adhesion to the concrete panel.

In recent years, “archibeton” is used to finish the exterior panels, which is the outer layer of concrete on white cement.

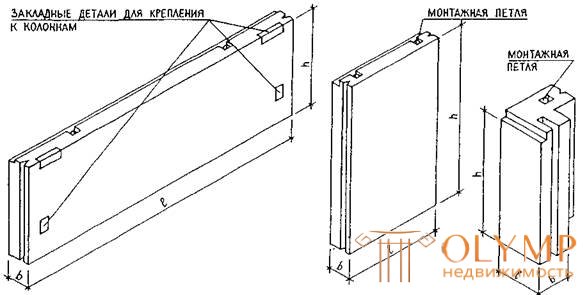

For the reliability of sealing joints in recent times change the very structure of the wall. The first option is to solve vertical overlapping joints with additional protection of horizontal joints with balcony tiles. The second option is to place vertical joints only within the walls of the loggias. Exterior walls in frame buildings are mounted and are mounted to fill the frame. Panels are made of two types: single-layer lightweight aggregate thickness of 300-350 mm; multilayered - with internal and external layers of reinforced concrete and effective insulation (Fig. 129, 141, 142.).

The panels are based on special elements of the ceiling and are attached to the reinforced concrete frame with the help of assembly welded joints.

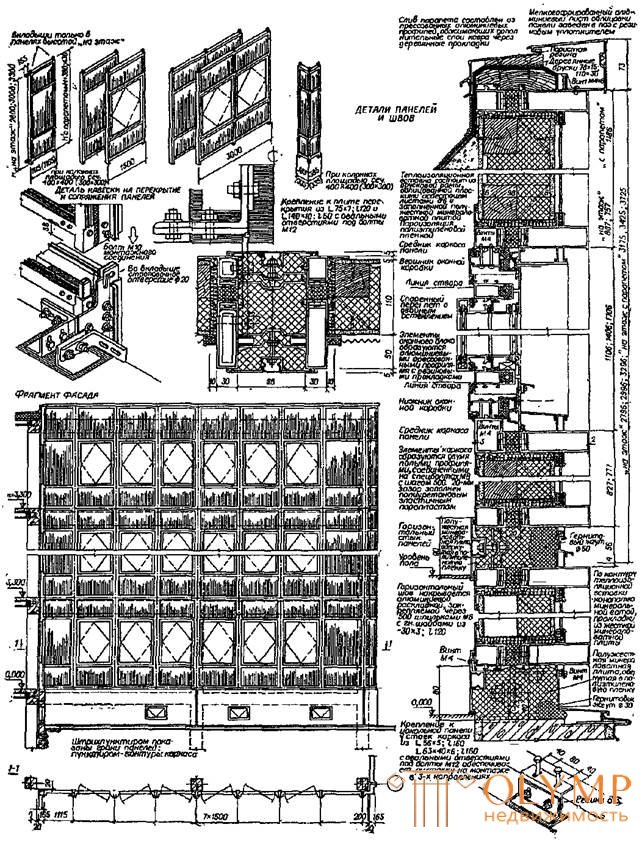

Aluminum structures are used for durability and decoration, which for a long time retain a good appearance. Their use allows you to create diverse architectural solutions, to achieve a meaningful appearance of the building. Widely used in the frame construction of fencing in the form of light hinged glass panels ( Fig. 142. ).

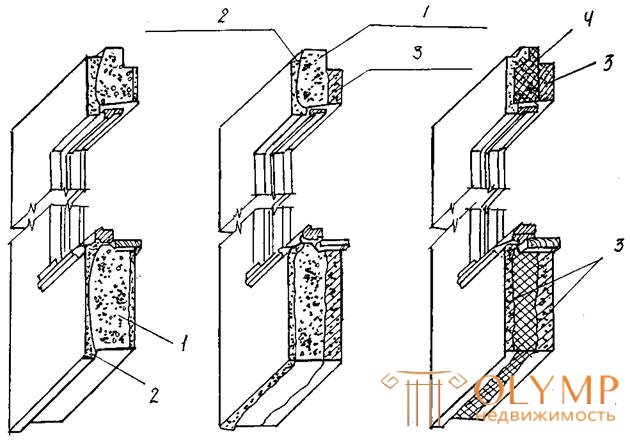

Fig. 122.

CONCRETE PANELS OF EXTERNAL WALLS

but

b

at

a - single layer; b - double layer; in = three-layer;

1 - constructively - heat-insulating concrete; 2 - protective - finishing layer; 3 - constructive concrete; 4 - effective insulation

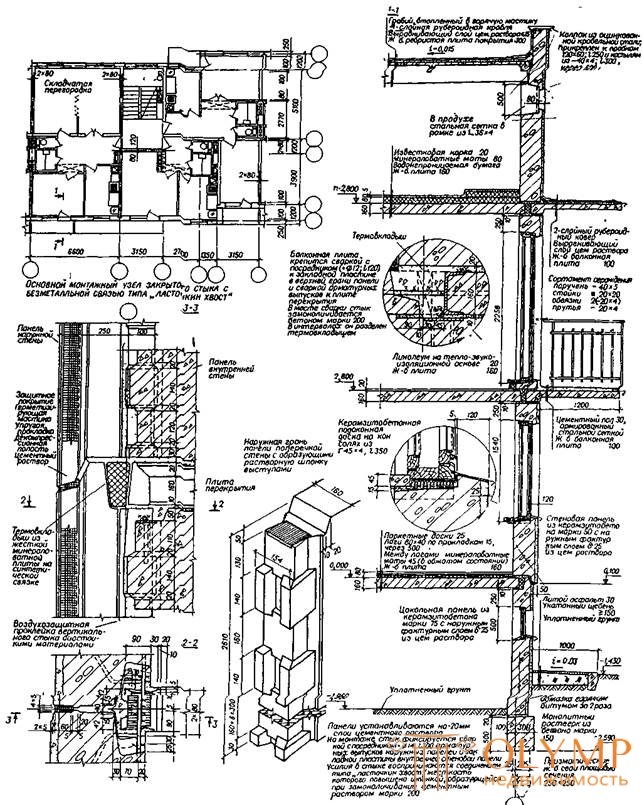

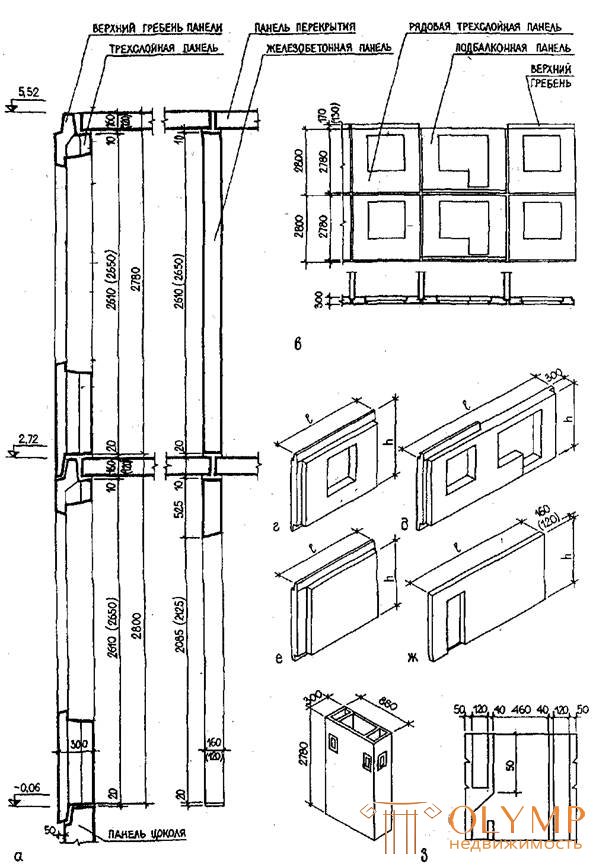

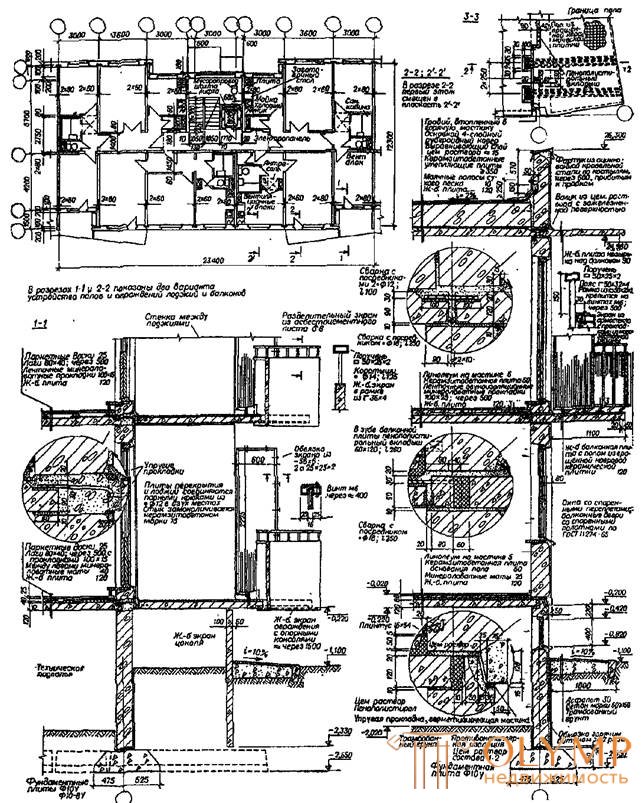

Fig. 123.

FLOOR PANEL RESIDENTIAL HOUSE WITH LONGITTED WALLS (OPERATED SERIES 108)

ROW SECTION

1 • 2 • 3 LATITUDE ORIENTATIONS

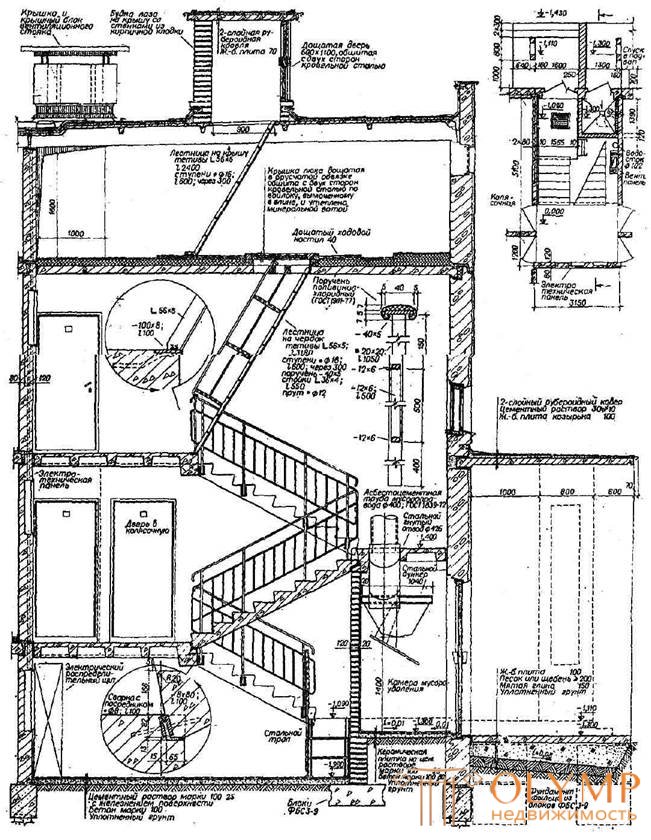

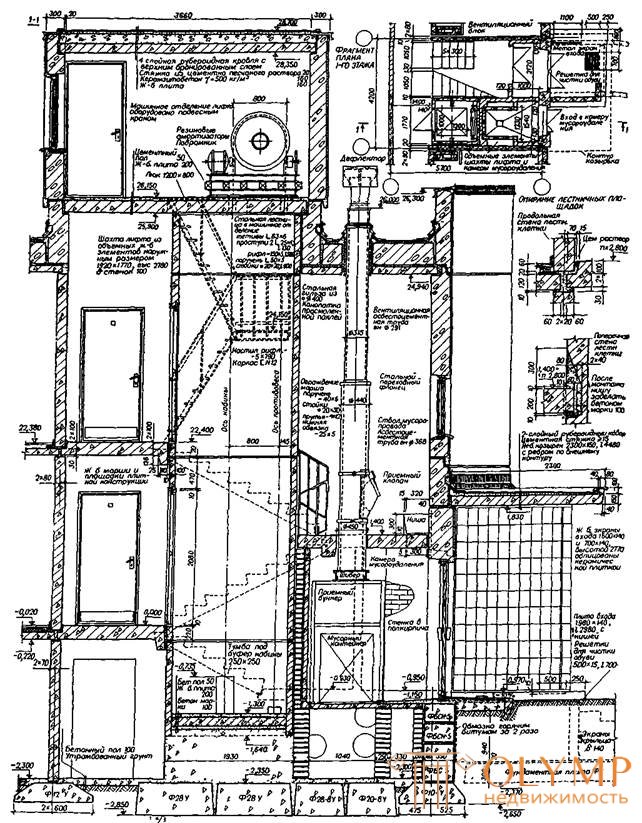

Fig. 124.

SECTION ON LADDER CELL

PLAN ON LEVEL 1 - FLOOR

Fig. 125

DETAIL OF THE ROOF

Fig. 126.

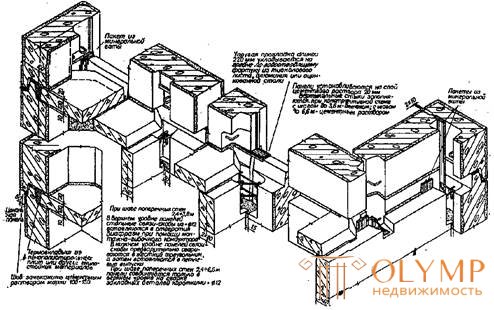

MAIN CONCRETE PANELS AND WALLS OF THEM

a - ordering the outer wall of three-layer panels; b - ordering of the inner wall; in - cutting the outer wall of one-step three-layer panels; rf is a three-layer panel of the outer wall, ordinary one-step, under-balcony, two-step, end; W - inner wall panel; h - ventilation panel

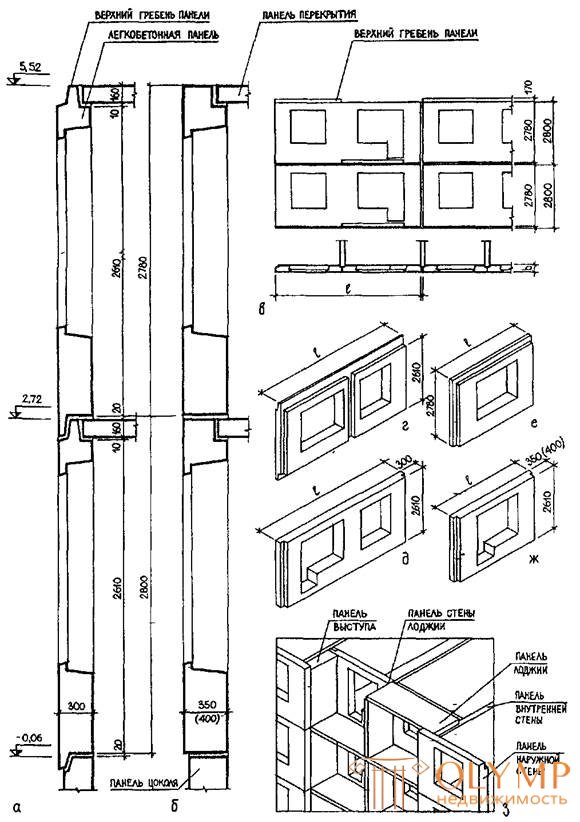

Fig. 127.

MAIN LIGHT-CONCRETE SINGLE-LAYERED PANELS

AND OUTER WALLS FROM THEM

a - ordering the outer wall with a thickness of 300 mm or less (with an anti-rain barrier); b - the same, with a thickness of more than 300 mm (without a barrier); in - cutting the outer wall of two-step panels with barriers; g, d - two-step panel, respectively, ordinary (with a barrier) and palletized; e, g - one-step panel (without barrier), ordinary and palletized; s - a fragment of the wall construction at the loggias

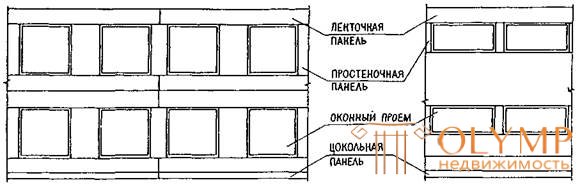

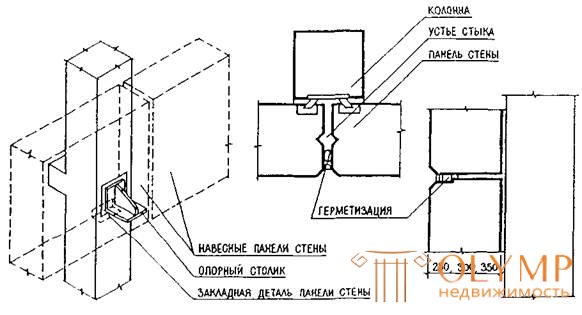

Fig. 128

EXTERNAL WALLS OF FRAME BUILDINGS FROM CONCRETE PLATES

CUTTING THE WALL

CUTTING WALL DOUBLE-ROW

PANEL SERIES TAPE

PANEL SHEET

ANGULAR PANEL

FASTENING OF HINGED PANELS TO COLUMN

VERTICAL JOINT OF SELF-SUPPORTING PANELS

HORIZONTAL JOINT OF SELF-SUPPORTING PANELS

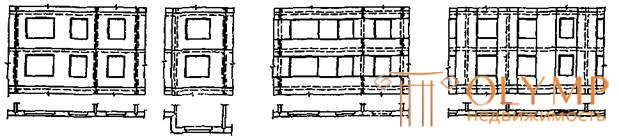

Fig. 129.

CUTTING AND JOINTING IN EXTERNAL WALLS FROM CONCRETE PANELS

SINGLE-RANGE OF PANELS SIZE "ON 1-2 ROOMS"

SAME WITH ANGULAR PANELS

DOUBLE RANGE FROM BELT PANELS LONG "ON 1-2 ROOMS" AND WICKET PANELS

VERTICAL FROM THE WALLPANE PANELS WITH A HEIGHT "ON 1-2 FLOORS" AND INTERLACE AND WINDOW PANELS

It is used in load-bearing, mounted and self-supporting walls. Forms an element of the structural cell of the panel system, connected at the joints by transverse walls and floor slabs

The same on the facades with rhizolites

It is used in curtain walls of any number of storeys, bearing and self-supporting walls of a building up to 5 m in height, allows reducing pogonazh joints and using for the heat treatment of products aggregates of small size

It is used in curtain walls. The technological features similar to the double-row cutting. Forms vertical divisions of the facades. Horizontal joints of the wall panels can be located at the bottom of the windows.

CLOSED JOINT

DRAINED BUTTON

OPEN JOINT

WATER AND AIR INSULATION IS PROVIDED:

Filling horizontal joints with cement mortar; vertical - concrete; air shielding sizing vertical junction; sealing the mouth of the joint with mastic on sealing gaskets;

Additionally - a labyrinth section of the horizontal joint; removal of moisture penetrated beyond the isolation zone through vertical decompression channels through floor drain holes 50x20 at the intersection of the joints

Additionally - a labyrinth section of the horizontal joint; removal of moisture penetrated beyond the isolation zone through vertical decompression channels through the open mouths of horizontal joints; removal of external moisture on the vertical water screens of weatherproof tapes

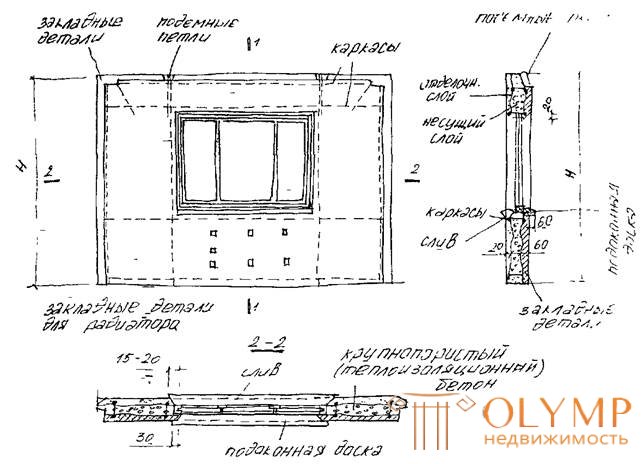

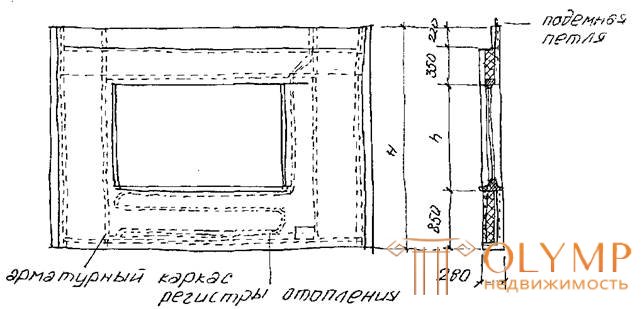

Fig. 130.

WALL PANEL STRUCTURES

THREE-LAYER WALL PANEL WITH A HEATER FROM CEMENT FIBROLITE

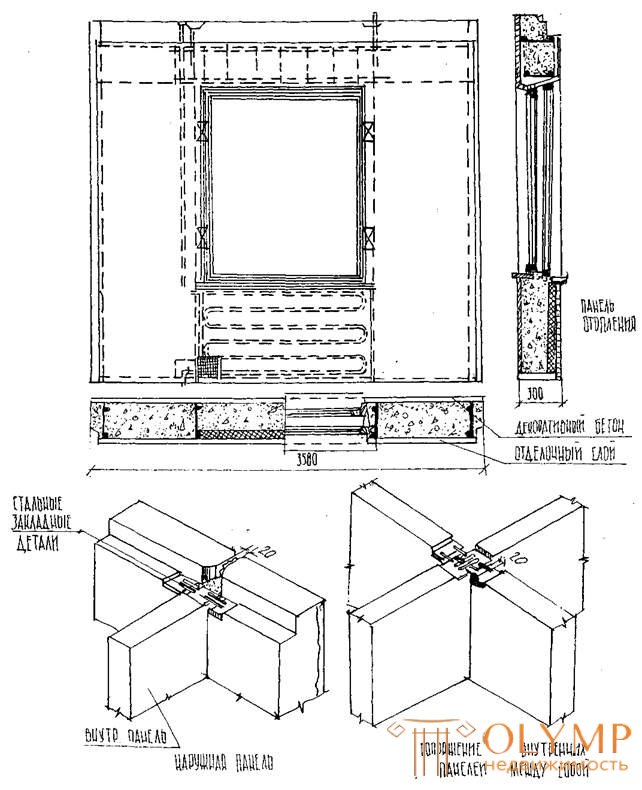

Fig. 131

CERAMZIT CONCRETE SINGLE LAYER WALL PANEL

Fig. 132.

EXTERIOR WALLS FROM SINGLE-LAYER PANELS FOR SINGLE-RANGE CUTTING OF BUILDINGS TO A HEIGHT UP TO 9 FLOORS (ON SERIES 1.132-1)

PROLON WALL PANELS:

LADDER CELL; At the butt of RIZALIT;

ROW - SIZE FOR 2 ROOMS

CROSS WALL PANELS:

IN THE END OF RIZALITA; IN THE END OF THE BUILDING

SCHEME OF CONSTRUCTIVE REINFORCEMENT

PARTS DETAILS

PLAN FOR TOP PANELS

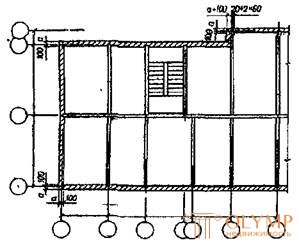

Fig. 133.

EXTERIOR WALLS FROM THREE-LAYER PANELS FOR SINGLE-RANGE CUTTING OF BUILDINGS TO A HEIGHT UP TO 16TH FLOORS (ON SERIES 1.132-3)

Fig. 134.

NINE-FLOOR RESIDENTIAL HOUSE WITH A “SMALL” STEP OF TRANSVERSE WALLS AND EXTERNAL WALLS FROM CERAMZIT CONCRETE PANELS (ACCORDING TO 90 SERIES)

36 - APARTMENT UNIT-SECTION 1B-2B-3B-3B

TYPE FLOOR PLAN

Fig. 135.

Fig. 136.

Fig. 137.

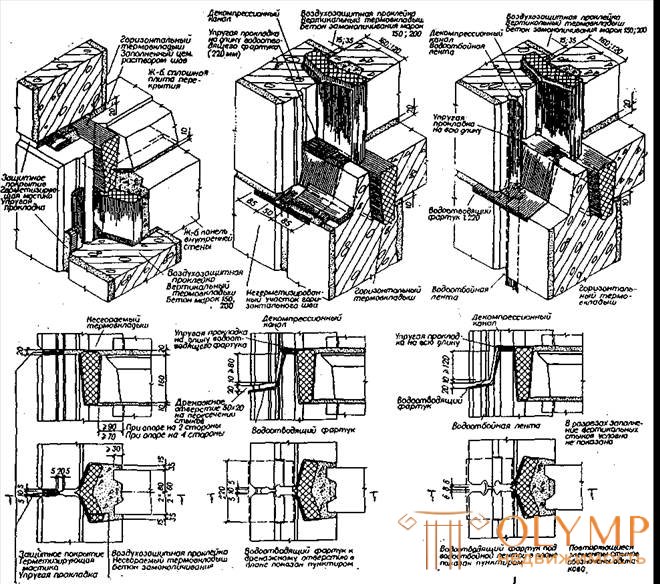

Fig. 138.

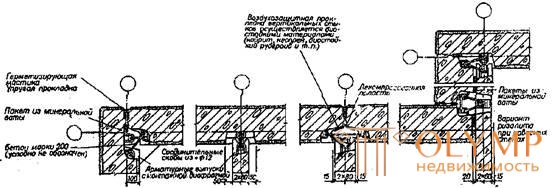

JOINTS OF 3-LAYER CONCRETE PANELS OF EXTERNAL WALLS

a - vertical joint with a decompression cavity; b - mating of ledge panels (risalit) at the loggia; in - horizontal joint; g - fastening the floor panel to the outer wall

Fig. 139.

VERTICAL JOINT OF PANELS OF INTERNAL WALLS

a, c - joints of transverse and longitudinal wall panels; b, d - junction of the panels of the transverse walls to the longitudinal wall (welding of embedded parts is conventionally not shown)

Fig. 140.

Fig. 141.

WALLS OF FRAME BUILDINGS FROM ALUMINUM PANELS (FOR THE SERIES II-04)

PANELS HIGH "ON THE FLOOR" AND TO "FLOOR WITH PARAPET" WITH HORIZONTAL CUTTING AT THE TOP OF THE OVERLAPPING

Fig. 142

Что бы оставить комментарий войдите

Комментарии (0)