The coating of the building or the roof is the upper structure of the building, which serves to protect against precipitation, rain and melt water. Its other main function is thermal insulation (heat preservation and protection against overheating).

Roof requirements:

1. Water resistant;

2. Sufficient strength, stability and durability;

3. Fire resistance;

4. Industry;

5. Efficiency

Roofs consist of supporting structures that, in addition to their own weight, receive loads from snow, wind and a waterproof shell - the roof.

For removal from the roofs of rain and melt waters they are given slopes.

Depending on the slope of the roof are divided into:

Sloping (with a slope of more than 10 °);

Slope rolls (4-10 °);

Flat (0-4 °).

The shape of sloping roofs is adopted depending on the geometric shape of the building in terms of and architectural considerations.

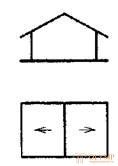

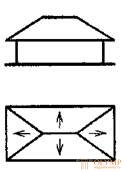

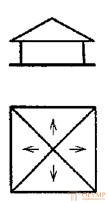

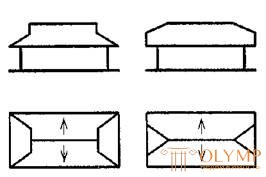

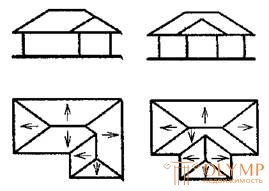

Roofs can be single-slope, double-slope, four-flat (hip, half-flat) and multi-slope, as well as pyramidal, conical, domed and vaulted (Fig. 63).

Ramps - sloping roof planes.

Triangular ramps - hips .

The intersection of the slopes, forming the protruding angles - the edges .

The intersection of the rays, forming the incoming angles - endovy or gutter .

The ridge is an upper horizontal edge.

The lower edge of the slope - the edge of the roof .

All slopes of the roof above the building, as a rule, are made of the same slope, the value of which is determined depending on the roof material and the climatic conditions of the construction area.

When constructing a roof plan with the same slopes of the slopes, the projections of the ribs and valleys always run along the bisectors of the corners and, therefore, in buildings of rectangular shape - at an angle of 45 ° to its sides.

Bearing structures of pitched roofs

They are made of wood, steel and reinforced concrete - in the form of rafters, roof trusses and large panels.

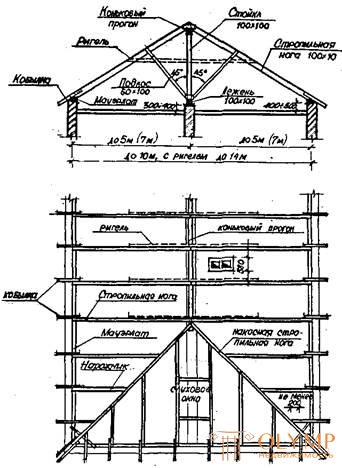

The choice of design depends on the location of the supports in the building, the size of the span, the roof slope, fire resistance requirements, capital, etc. (fig. 64, 65, 69, 70, 74).

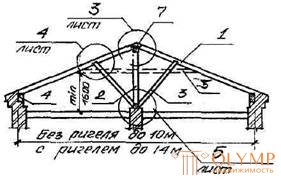

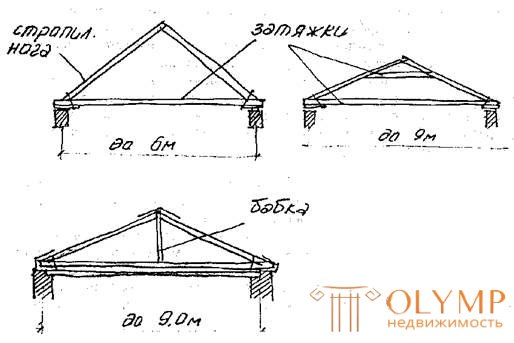

The beam truss construction of a gable roof can be solved in the form of laminated or hanging rafters, the main element of which are beams that are laid at an angle according to the slope of the roof on the external walls and internal supports (laminated rafters) ; and in the absence of the latter - only on the outer walls (hanging rafters) .

Rafter rafters

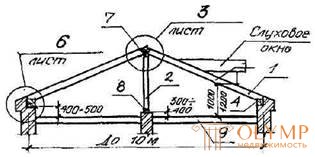

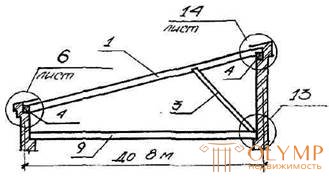

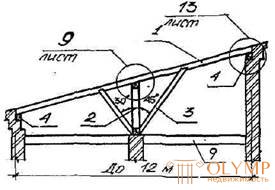

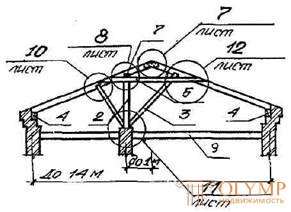

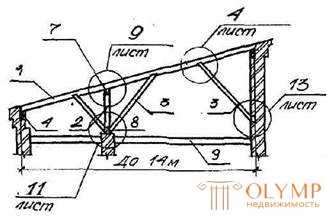

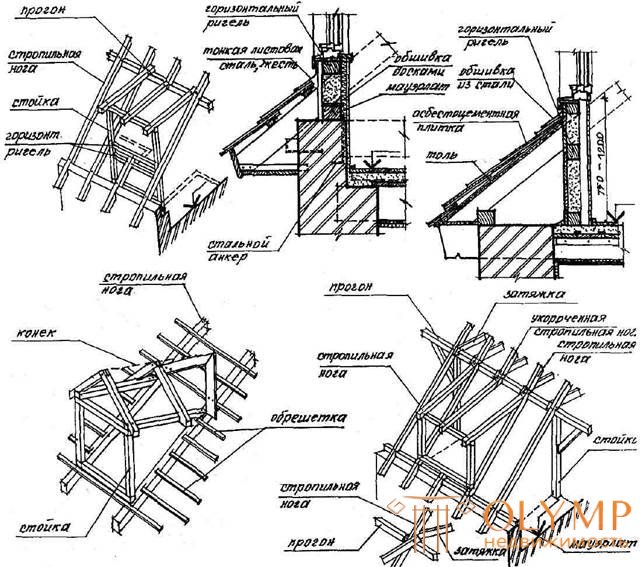

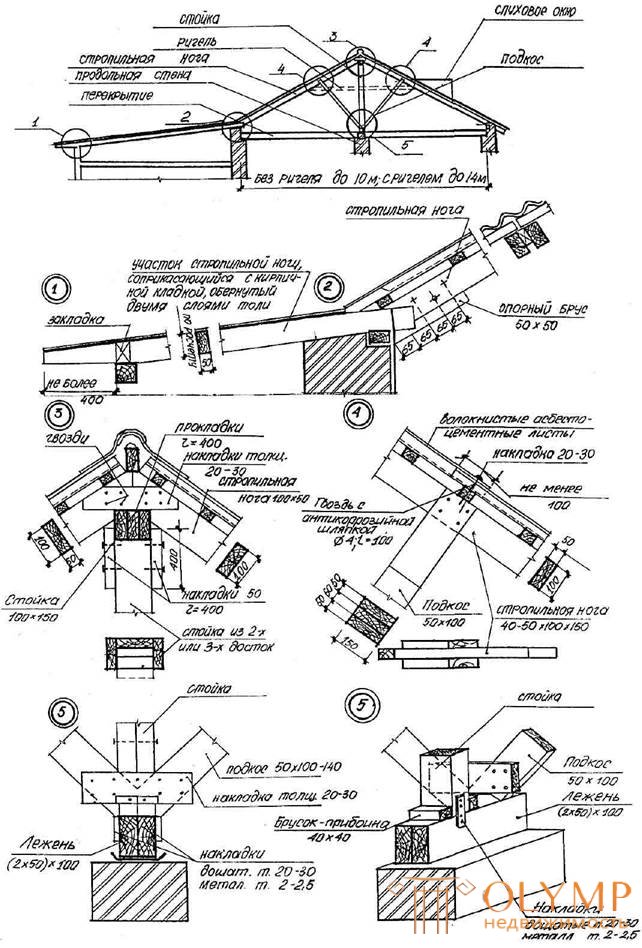

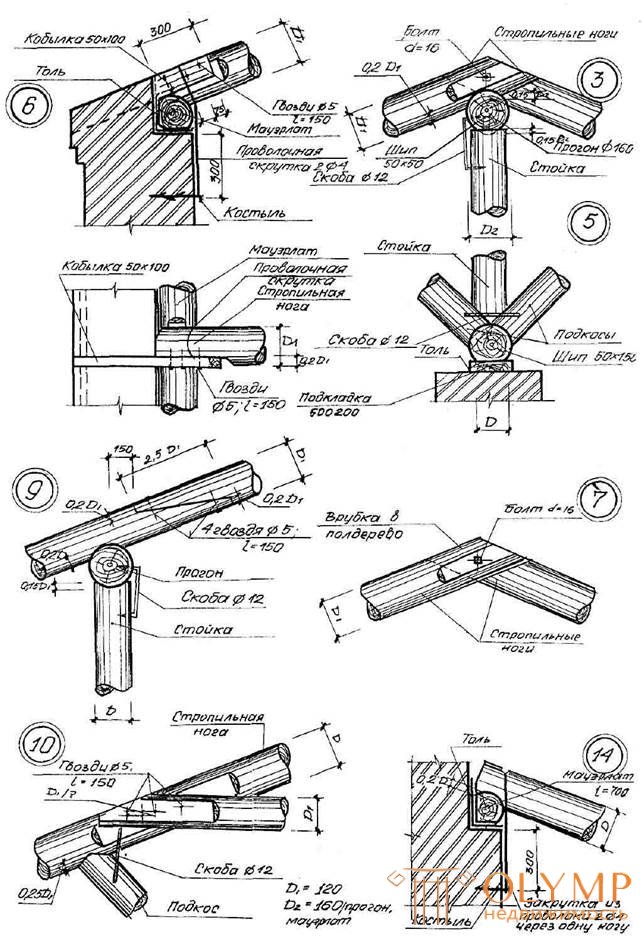

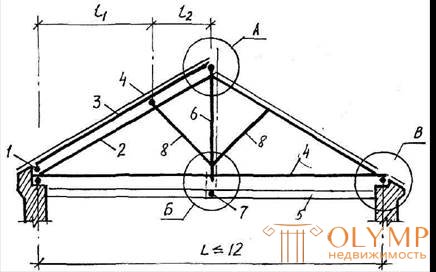

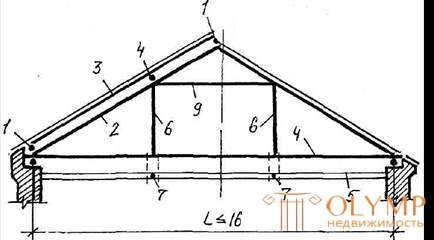

Suspended rafters are used in cases where the building has two or more rows of vertical supports (walls or pillars), the distances between which do not exceed 5-8 m. Such spans overlap inclined beams (truss legs) from boards, bars or logs that They are arranged along the slopes at a distance from each other in the axes (rafters step) 0.8 ... 1.2 m and more (Fig. 64, 65, 69).

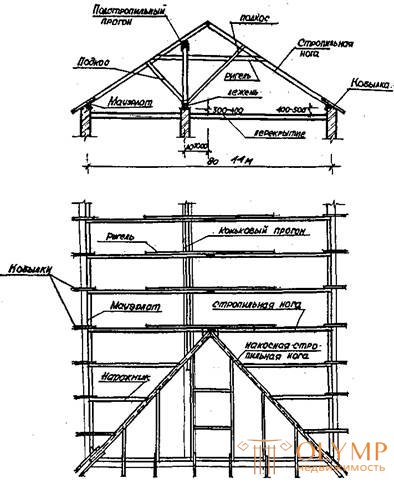

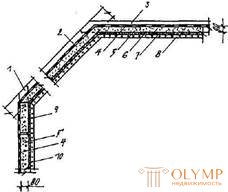

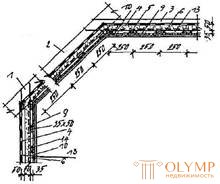

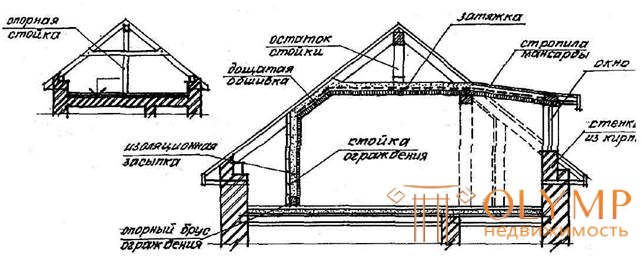

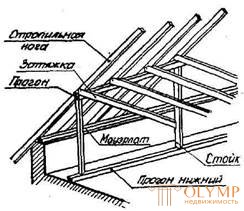

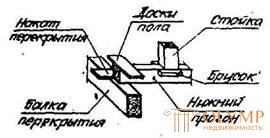

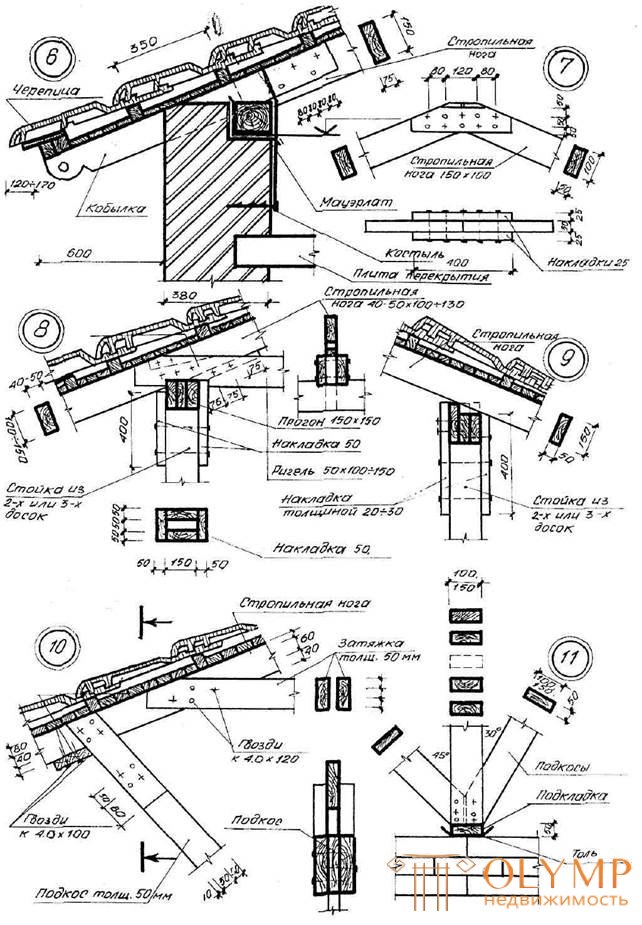

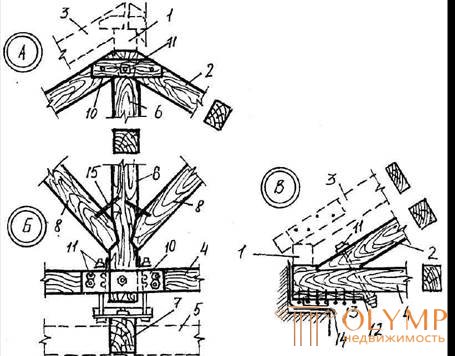

Internal walls and pillars are adjusted to 15-20 cm above the top of the attic floor. On them are laid the rails, on which the racks are installed (with a step of 4-6m) supporting the upper longitudinal beam - girder. The construction legs are laid on the girders, and the lower ends of these legs on the subrafter bars are mauerlates (Fig. 69, 70, 71, 72).

For stiffness and stability between the uprights and the purlins, as well as for unloading the building legs, the struts are inserted (Fig. 64, 65).

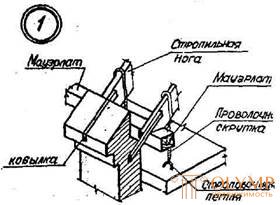

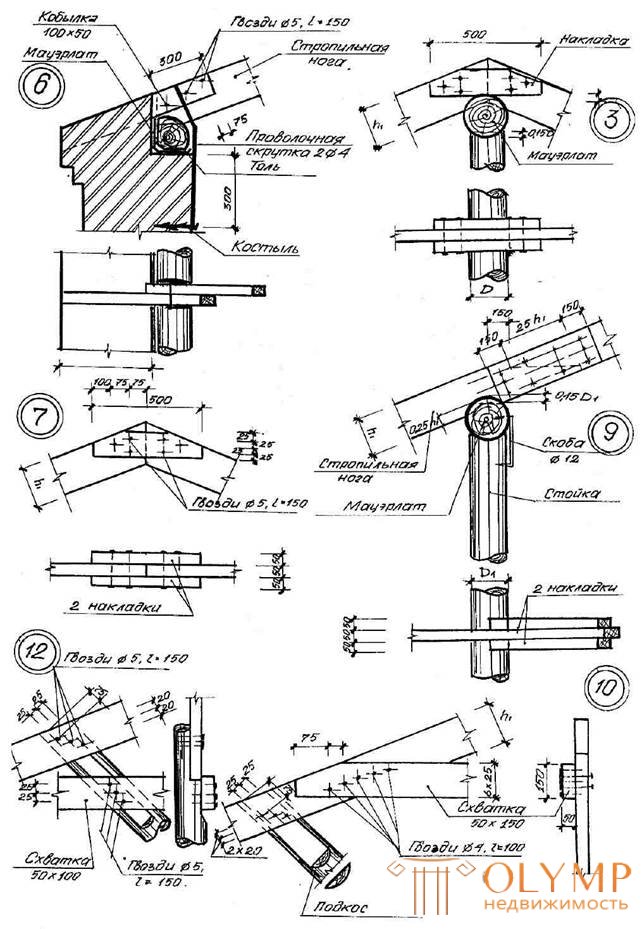

In order to prevent the roof from breaking down by the wind, the building legs through one fasten with a wire twist (diameter 4-6 mm) to a crutch or ruff embedded in the wall (or to the beam elements of the attic floor) ( fig. 70, 71, 72).

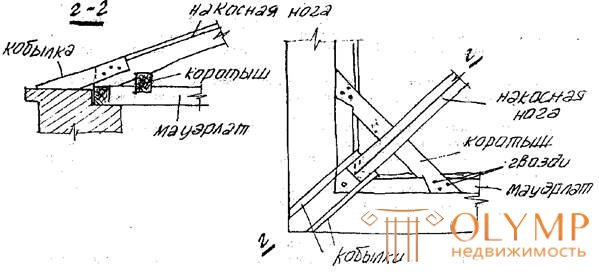

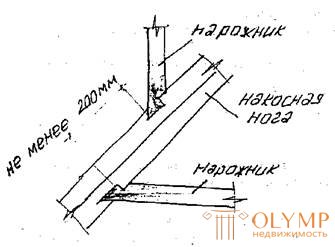

Diagonal (or nososnye) rafter beams are supported in the ridge either on the ridge girder or on the rafters of the rafter legs. The rafter legs and stitched rafter beams must not come into contact with the masonry of the eaves of the walls in order to avoid rotting.

All sizes of wooden elements of nylon rafters are determined by calculation. Mauerlats and lezhny are antiseptic and are placed on stone walls lined with roofing.

At present, prefabricated prefabricated wooden rafters of prefabricated prefabricated wooden trusses have become widespread in mass construction in the form of ready-to-install shields.

The rafter shield consists of rafter legs, bar obreshetka and diagonal braces (for rigidity) and fits on inclined

subrafter frames (fig. 80).

Prefabricated reinforced concrete rafters were not widely used, despite the fact that they are durable, economical, and fireproof.

Hanging rafters

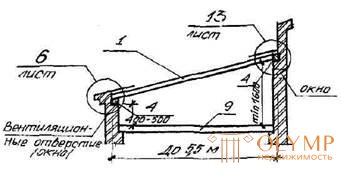

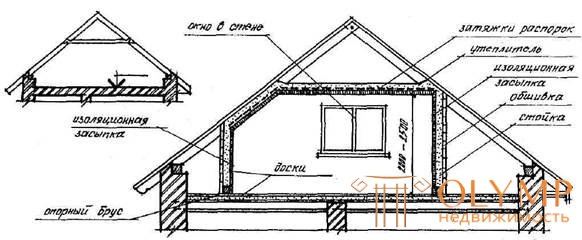

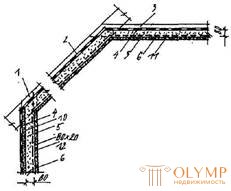

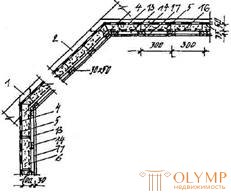

Hanging rafters are used in cases where the building has no internal wall supports or pillars (fig. 73, 74). In these cases, the span between the outer walls overlap trusses. The use of these trusses in the attic roofs is aimed at simultaneously resolving two issues: in the absence of internal supports to form a single, gable roof and, under the same conditions, suspend the supporting structures of the attic floor.

The material of hanging rafters of pitched roofs is mainly wood in the form of boards, beams, and logs. Stretched elements are sometimes made of steel rods (trusses are called metal-wood). Metal trusses are rarely used.

When installing truss trusses, the attic floor structure is suspended on steel clamps to the tie down of hanging trusses, or to the lower truss belt (fig. 74).

Such floors are called suspended . Suspended girders, in turn, carry perpendicularly arranged wooden beams between them, between which the inter-beam filling is laid the same as usual in the attic floors. However, it should be noted that in order to reduce the load on the hanging rafters or the rafter truss, it is necessary to choose a structure for a suspended ceiling, which has as little own weight as possible.

Farm building

Building trusses are a flat, geometrically unchangeable lattice system consisting of separate, interconnected elements ( rods) . The geometric shape may be different, however, mainly triangular trusses are used in civil buildings.

Roof trusses are: wooden, metal, steel and reinforced concrete.

Wooden trusses of the simplest structures are called hanging rafters (Fig. 73). Structural schemes of hanging rafters (Fig. 74 ).

Steel and reinforced concrete trusses have limited use in civil engineering (to be reviewed in the “industrial buildings” course).

The roofs that make up the “fifth facade” of buildings should also have architectural and decorative qualities: the surfaces of the roofs are viewed from the windows of higher buildings, they form the silhouette of the building and play an active role in the architectural panorama of the city. In those cases when the roof surface is used to accommodate recreational, play or sports grounds, open cafes, etc. (the roof is in use), its covering must also not only meet the architectural and decorative requirements. But also possess mechanical strength. In order to meet all the listed requirements, the roof must contain supporting elements, heat and vapor insulation, waterproofing and the base for it. The bearing elements of industrial roofs of civilian buildings are mainly made of reinforced concrete, thermal insulation from slab or backfill materials (expanded clay gravel, polystyrene foam, mineral or glass wool, fibrolite, cellular concrete, etc.)

All elements of the roof can be combined in one multi-layered structure (roof) or separated by attic space (attic roofs). Depending on the placement of the thermal insulation layer, there are attic roofs with a warm or cold attic. The latter is the most common design, and in the traditional (for wooden rafters), and in industrial housing. Combined roofs are used mainly in public buildings. In residential buildings such roof constructions are allowed to be used with a house height of up to four floors.

SINGLE

TWO-SCALE

FOUR-SCALE

Shatrovaya

SEMI VALVES

MULTI-SCALE

DOME

CONSIDERED

PYRAMIDAL

Conical

Fig. 63.

Fig. 64.

SINGLE ROOFS

Double roofs

Podkosy stand under each truss foot

SUB SLAYS BECOME ONLY IN THE PLACES OF THE RACKS OR BEFORE EACH TRIPPING LEG

Podkosy stand under each truss foot

1 - truss foot;

2 - stand;

3 - strut;

4 - under-rafter bar (mauerlat);

5 - bolt;

6 - strut;

7 - upper run;

8 - lying down;

9 - overlap

Fig. 65.

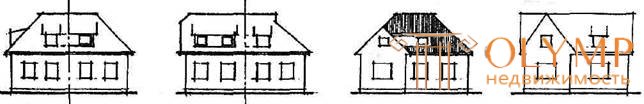

ACCOMMODATION OF HEARING WINDOWS ON ROOFS OF DIFFERENT FORMS

EXAMPLE OF THE USE OF UNDERGROUND SPACE

LIGHT CONSTRUCTION OF ATTIC OCCURATION, SUSPENDED TO THE CONSTRUCTIONS (BEARING WITH PLASTER IN THE REED)

EASY SUSPENDED COVERAGE FROM WOOD-CEMENT PLATES OF 2.5 CM THICKNESS WITH PLASTERS AND THERMAL INSULATION OF MINERAL WOOL OF 5 CM THICKNESS

SUSPENDED CONSTRUCTION OF ATTIC OCCRUPTION FROM QUALITATIVE STRIPPED DOSCOWS WITH THERMAL INSULATION FROM THE MINERAL WOOD WITH A THICKNESS OF 8 CM

LIGHT CONSTRUCTION OF SUSPENDED ATTIC OVERLAY WITH A WOODEN-FIBROUS PLATES AND THERMAL INSULATION FROM GLIN CONCRETE

1 - stand; 2 - truss foot; 3 - tightening; 4 - roofing material (rolled material); 5 - mineral wool mats; 6 - roofing asphalt; 7 - filing 1.5; 8 - plaster on reed; 9 - cement spray and lime plaster; 10 - wood - cement plates; 11 - facing of planed boards with a coating of 2 cm; 12 - facing from 6x2 planks; 13 - air gap; 14 - rake; 15 - slabs of clay concrete; 16 - roofing paperboard; 17 - 4mm sololith.

Fig. 66

EXAMPLE OF THE USE OF UNDERGROUND SPACE

MANSARD WITH SUPPROVED WALL, WHICH COMPLETES A WINDOW

CONSTRUCTIONS OF SMALL AND LARGE HEARING WINDOWS APPLICABLE FOR LANDSETS LIGHTING

Fig. 67.

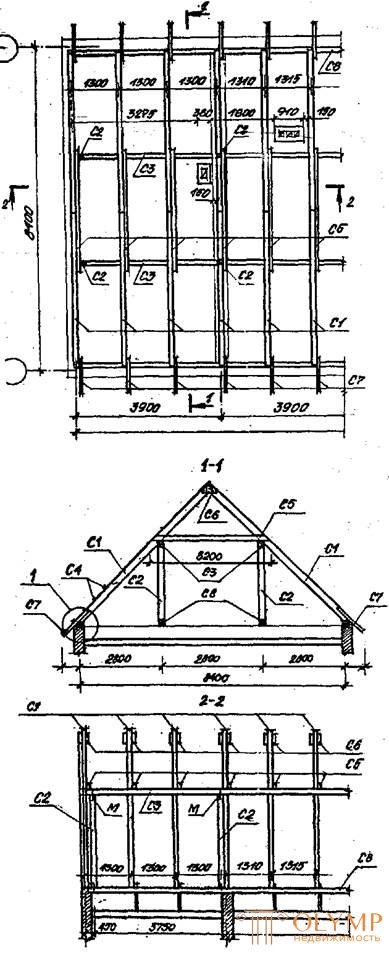

STROPIL PLAN

LEAKAGE RACK ON BOTTOM RANKS

TRIMPING LEGS ON MAUERLAT AND FASTENING THEM WITH WIRE BODIES

BACKGROUND ELEMENTS

MARK

NAME OF MARK

SECTION, MM

LENGTH,

MM

C1

Truss foot

50

150

6150

C2

RACK

100

150

2180

C3

RUN

100

150

C4

TROUBLE

40

50

3240

C5

TIGHTENING

60

40

3200

C6

COVER

40

120

440

C7

HOLIDAYS

40

140

430

C8

LOWER RUN

100

150

4100

M

BRACKETS

Ø

12

300

Fig. 68

Fig. 69

Fig. 70

Fig. 71

Fig. 72.

TRAINING FEET ON MAUERLAT

HANDWAY CUTTERS

CONSTRUCTIVE DIAGRAMS OF THE LOOP TRAILS

Fig. 73.

HANGING TRIMPERS OF CATTLE ROOFS

1 - run; 2,4 - upper and lower truss belts; 3 - truss foot; 5 - attic floor beams; 6 - stand; 7 - attic floor girder; 8 - strut; 9 - bolt; 10 - lining of the boards; 11- bolt; 12 - Pribina; 13 - antiseptic lining; 14 - tol; 15 - bracket

Fig. 74.

Что бы оставить комментарий войдите

Комментарии (0)