Partitions

Partitions are curtain walls, intended for dividing within the floor of large, limited by capital walls, volumes into separate rooms.

The area of partitions in residential and public buildings exceeds the floor area by about 2-2.5 times, their cost reaches 10% of the total cost of the building, and the labor intensity of construction is about 15% of the total labor input.

The following basic requirements are imposed on partitions:

1. Strength and stability;

2. perhaps a small thickness and weight;

3. proper sound insulation qualities;

4. the possibility of driving and secure nails;

5. industrialness;

6. profitability.

If necessary, there may be special requirements: water resistance, fireproof, airtightness, etc.

Depending on the material and construction, the partitions are divided into the following types :

1. slab - are made of small-sized factory-made slabs (gypsum, gypsum-concrete, foam silicate, etc.);

2. stone - made of brick, ceramic stones or light concrete blocks;

3. monolithic reinforced concrete ;

4. wooden;

5. large-size panel ;

6. from glass blocks and glass-core (fig. 90 - 97).

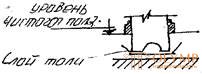

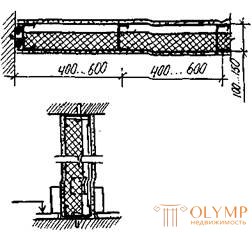

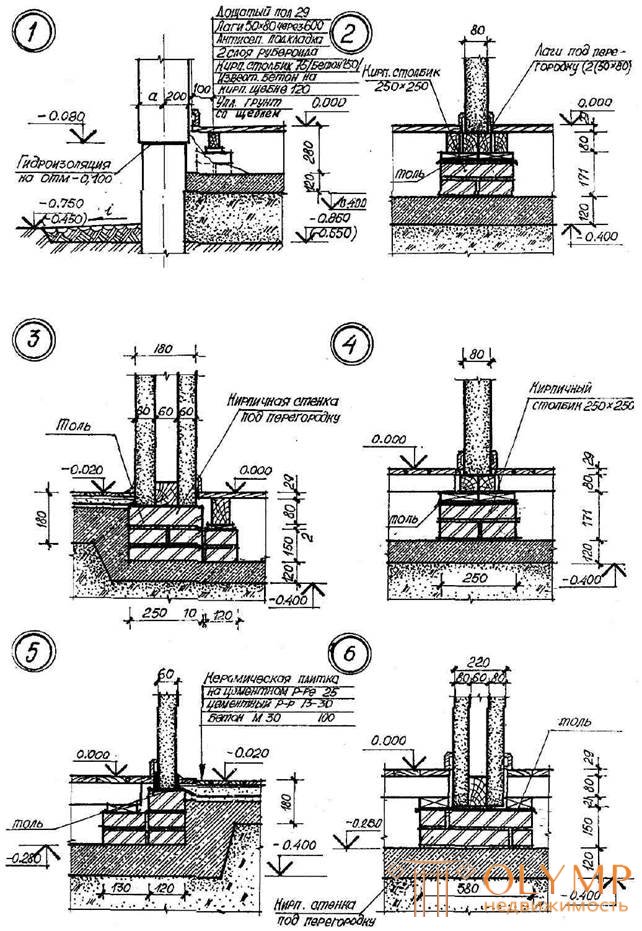

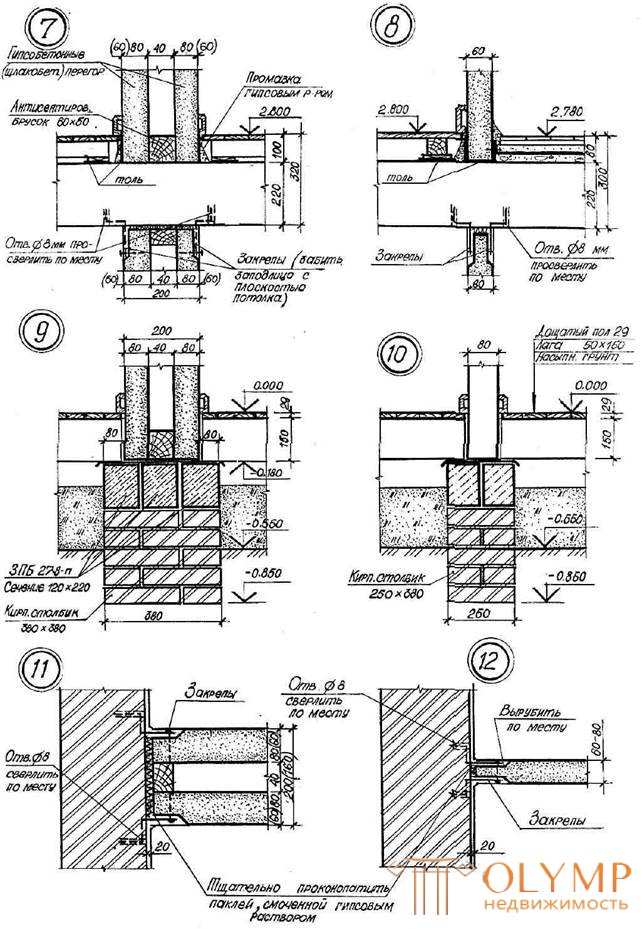

The supports for the partitions are the supporting elements of the floors (beams, panels), and in the first floors of baseless buildings and in the basement floors there are brick posts or concrete preparation (fig. 98, 99).

RETURN STAND FOR INSTALLATION OF DOOR UNIT

Software 1-1

Software 2-2

Software 3-3

Software 4-4

Software 5-5

EMPTY B / W PLATES

W / B STONES

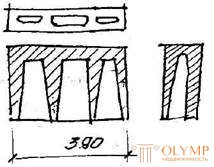

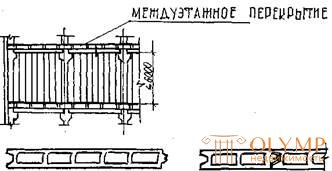

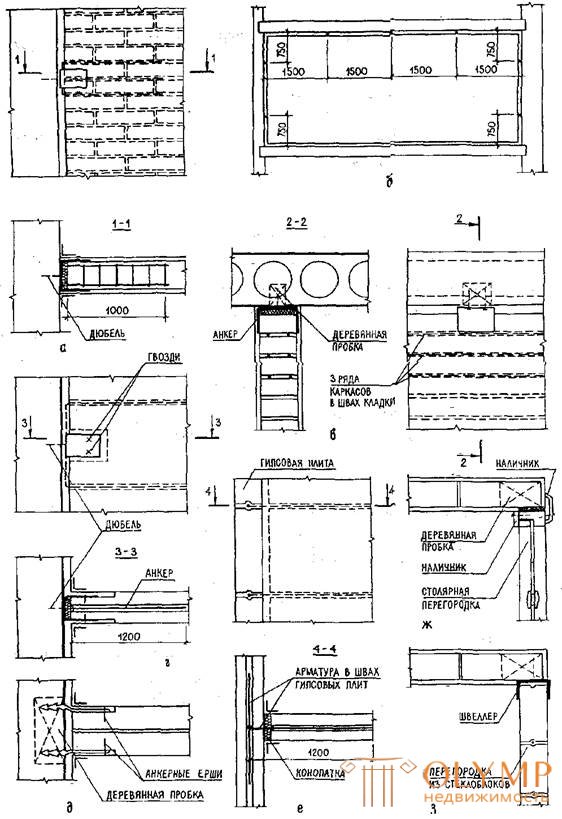

Fig. 90.

SMALL AND CLEVER-CONCRETE PARTITIONS

and - a partition from plaster or foam-concrete plates; b - gypsum boards reinforced with slats, reeds, etc .; в - hollow plaster stones (longitudinal half and efficient); g — variants of hollow ceramic stones; d - partition wall of hollow plasterboard; e - glass reinforced concrete partition; / - glass blocks; 2 - armature with a diameter of 4 mm; 3 - cement mortar; 4 - caulker; 5 - wooden layouts;

6 - door frame; 7 - elastic pads or jointing; 8 - anchor.

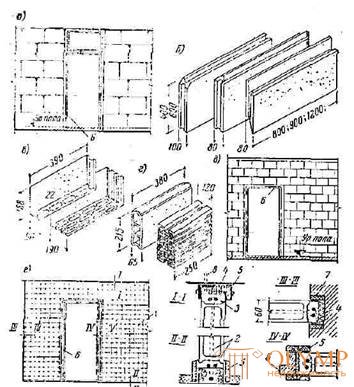

LIGHT BRICK PARTITIONS

a-with horizontal reinforcement with relatively small dimensions of partitions;

b — with reinforcement of the Cruz system; / - ordinary or lightweight brick "on the edge";

2 - wide reinforced seam; 3 — strip steel 1.5 x2.5 mm or pack iron;

4 - wire twist; 5 - wooden cork or door frame; $ - crutch or dowel; 7 — door box; 8 - roofing or skin-leather: 9 - partition wall;

10 - platband

Fig. 91.

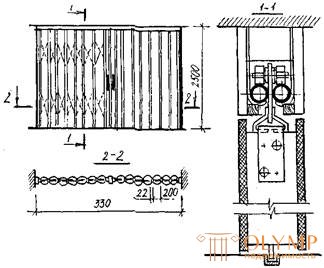

GLASS-CONCRETE PARTITION

1 - glass blocks; 2 - fittings Ø4mm; 3 - cement mortar; 4 - caulker; 5 - wooden layouts; 6 - door frame: 7 - elastic gaskets or jointing; 8 - anchor.

Fig. 92

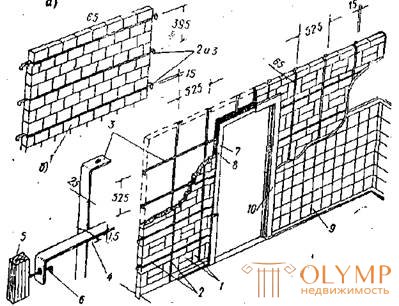

PLASTER PARTITIONS

Fig. 93.

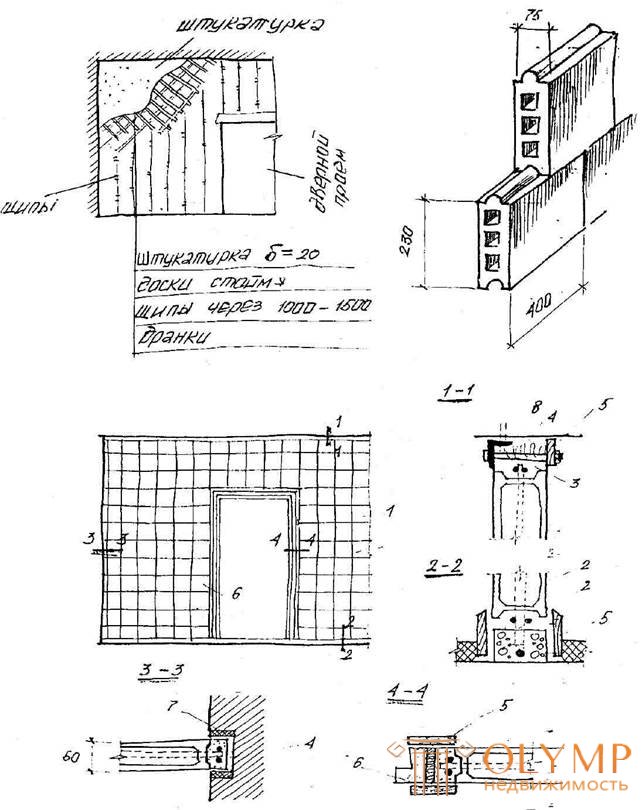

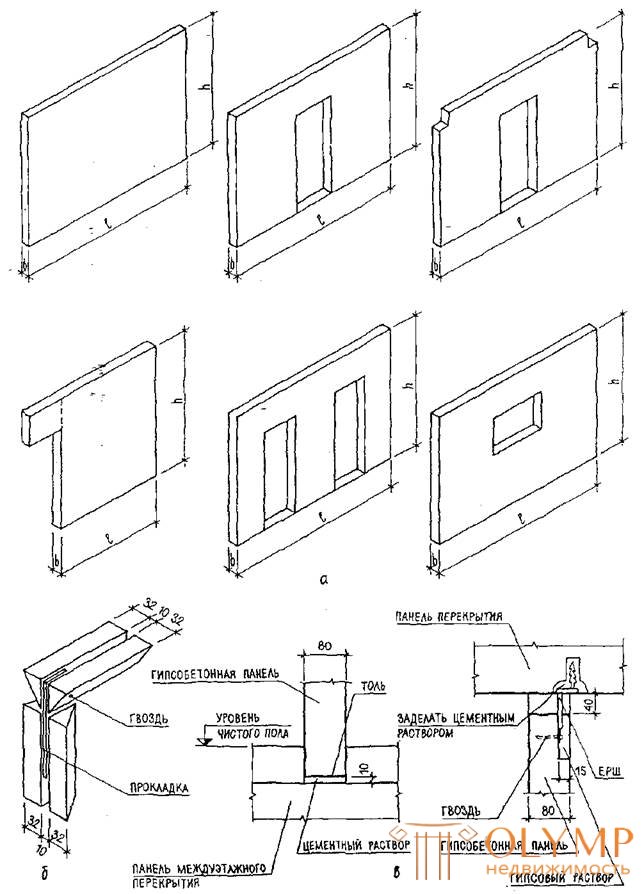

LARGE PANEL CONSTRUCTION PLANTS

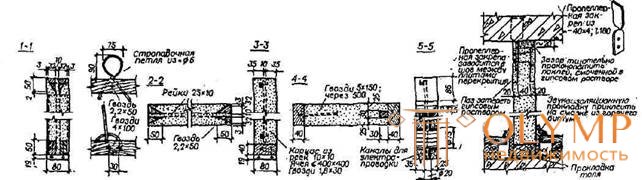

PARTITIONS FROM ASBESTOSCEMENT PANELS

FRAME PARTITION

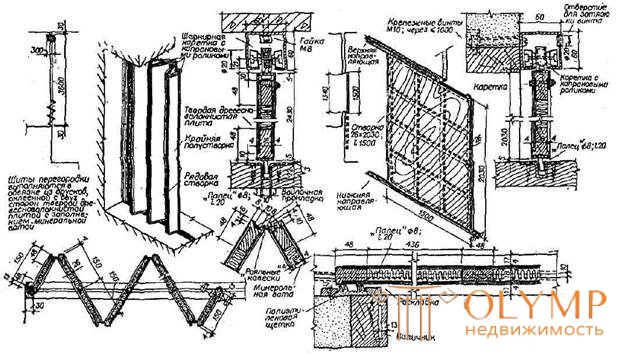

JOINTLY FOLDING PARTITION

Harmonous Partition

Fig. 94.

Partition structures.

Partitions of small-sized plates (Fig. 90, 91)

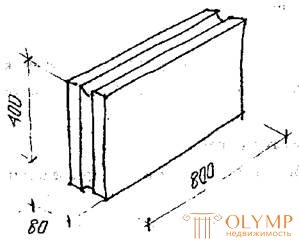

Partitions made of plaster, gypsum concrete or gypsum slabs are manufactured in sizes 800 * 400 * 80 with smooth front surfaces

Less labor-intensive partitions of slabs, the height of the floor (clean), at least half a floor, a width of 0.5; 0.6; 0.8 and 1.2 m. The plates are manufactured in the factory by the method of rolled or pressed steel from a flexible fiber mass with a bulk weight of γ = 850–950 kg / m3 or from gypsum concrete γ = 950–1300 kg / m3. Plate thickness 45mm.

Partitions of this size are also made of cellular concrete, fiberboard and other materials.

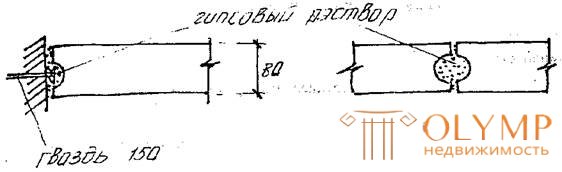

They are installed in one or two layers on a plank strip laid on the floor. For increased sound insulation, an air gap is arranged (40 - 60 mm wide).

As finishing use coloring, pasting by wall-paper or facing (fig. 93).

Partitions of gypsum boards are not allowed to be used in rooms with excessive humidity. In this case, slag concrete hollow slabs or stones, as well as hollow ceramic blocks, are used instead of gypsum slabs (Fig. 90, 91, 92, 95).

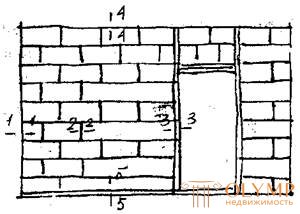

Brick partitions - have a thickness of 0.5 or 0.25 bricks. Partitions with a thickness of 0.5 bricks, if their height is not more than 3m, and the length is not more than 5m, spread out without reinforcement. In other cases, it is reinforced with pack steel with a cross section of 1.5 * 25 mm - into horizontal seams after 6 rows. Partitions with a thickness of 0.25 bricks are also reinforced with vertical reinforcement of packaged or round steel with a diameter of 4-6 mm (fig. 91, 95).

Reinforced concrete partitions - are performed in some cases - monolithic. Armature with a diameter of 5 - 6 mm, 200 * 200 grids. After demolding, the surface is rubbed with cement mortar. The thickness of the partition-δ = 60-80m.

Wooden partitions - are: board, frame panel and joiner (Fig. 92, 93, 94).

* Board partitions

Disadvantages : significant complexity and non-industrial (Fig. 92).

* Shield partitions . They are made of 2 and 3 ply to the entire height of the room with quarters for the convenience of rallying together (Fig. 93).

* Frame partitions - represent a number of racks (through 0.5-1.0 m) between the lower and upper straps. They are sheathed on both sides with boards 20-25mm. The filler may be bulk or board material.

* Joiner's partitions are made of prefabricated wooden shields, deaf or glazed. They are used in public buildings for fencing auxiliary premises (Fig. 97).

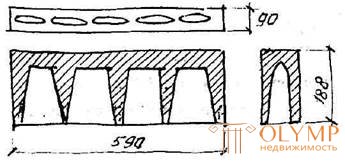

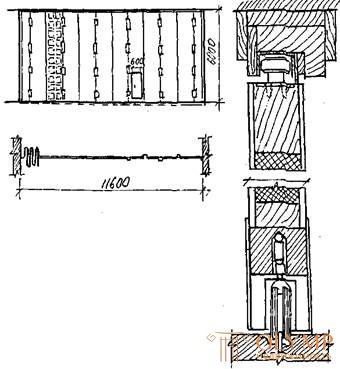

Large-panel partitions - "on the room" - the most industrial. They are made of gypsum slab concrete reinforced with wooden frames from battens 10mm thick.

At the device of interroom partitions install 2 panels with an air gap between them 40mm thick (Fig. 96, 97).

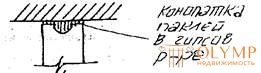

Partitions made of glass blocks are laid out on cement mortar with gasket in the grooves between the blocks of vertical and horizontal reinforcement in the form of rods or strips (Fig. 91, 92).

Partitions from stekloprofilit assemble from elements (mainly a box-shaped profile), made on glass factories, with a height equal to the height of the partition. Such elements are placed between the upper and lower straps with the sealing of the joints with special mastics.

Soundproofing events.

One of the most effective techniques is the air gap. Partitions without an air gap with enhanced sound insulation properties are made of a layered structure with a lining in their thickness of a layer of mineral felt, cardboard or other low-sounding materials.

1. Partitions in capital buildings must not be installed on clean floors or logs.

2. When installing partitions across beams, it is necessary to eliminate airborne noise; arrange special vertical diaphragms (caps) made of concrete, brick or other dense materials, not less than the thickness of the partition, below the bottom of the partition along its entire length.

3. It is necessary to penetrate the gaps between the partition and the main wall, and between the partitions, and seal them with a solution.

4. Partitions should not be brought to the ceiling 10-15mm. The gap is thoroughly smoked with tow soaked in solution, and then sealed with a solution on both sides to a depth of 20-30mm.

The partitioning of the partitions on the supporting elements of the floor should be carried out through the mortar joint or elastic gaskets.

The experience of using large-panel partitions - in town planning showed their high technical and economic efficiency.

PARTITIONS FROM FINE AND PLATE MATERIALS

and - fastening of a brick partition to a wall; b - layout of attachment points of the partition to the walls and floors; в - node for fixing the partition to the ceiling; (d) fastening of gypsum wall partitions to the wall using an anchor; d - the same, paired with the help of ruffs; e - the same, from the plaster plates joined perpendicularly; W - junction of brick and carpentry partitions; the same, and glass-block partitions.

Fig. 95

PLASTIC CONCRETE PANELS FOR PARTITIONS AND THEIR PARTS

and - panels; b - wooden frame panel; в - junction of the partition panels to the floor panels

Fig. 96

STATIONARY PARTITIONS FROM PLASTIC CONCRETE PANELS OF FACTORY PRODUCTION

ROLLED

CONCRETE IN VERTICAL FORMS

CONSTRUCTION PRODUCTION

DETAILS OF PANELS AND FASTENINGS

TRANSFORMING- FOLDED AND ROLL-UP PARTITIONS OF THEIR WOODEN RODS

Fig. 97.

Fig. 98

BETWEEN APARTMENTS

IN THE BATHROOMS

INSTALLATION OF PARTITIONS 1ST FLOOR

FLOORS BY J.-B. FOR RUNNING

FASTENING BULBS TO WALLS

Fig. 99

Что бы оставить комментарий войдите

Комментарии (0)