Compressed air is used as a drive for pneumatic equipment and tools (demolition hammers, drilling equipment, pneumatic vibratory hammers, paint and sandblasting machines, etc.). Compressed air is also required for the pneumatic transport of solutions and pulverized materials, expanded clay gravel. Oxygen and acetylene are used for welding. At the PIC stage, the need for compressed air and gas is calculated according to the norms for 1 million rubles. estimated cost of construction and installation work.

Usually the need for compressed air is satisfied by mobile compressors equipped with flexible hose sets, as well as cylinders. For painting mechanisms, high-capacity compressors are used, which are part of these units and are not considered as a general calculation. Oxygen and acetylene are supplied to the facility in 40-liter steel cylinders and stored in inventory depots, where they must be protected from overheating. In addition, mobile acetylene plants are used, as well as portable acetylene generators.

Compressed air networks are performed only on objects with large concentrated volumes of work (metallurgical networks, CHP plants, etc.). in this case, the sources are permanent or temporary compressor stations. Compressed air from them is supplied through steel pipelines to the places of distribution, and from them through rubber hoses - to workplaces.

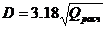

For approximate calculations, the diameter (mm) of the pipeline is calculated by the formula:

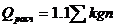

Qrassch - the required amount of air in the calculated area.

where 1.1 is the coefficient taking into account the loss of air in the pipelines (from the leakiness of the joints and from cooling in winter) and the flow rate for purging;

k - coefficient taking into account the simultaneous operation of homogeneous mechanisms (for 2x - k = 1.0, for 15 - k = 0.6);

g - compressed air consumption by appropriate mechanisms;

n is the number of homogeneous mechanisms.

Что бы оставить комментарий войдите

Комментарии (0)