In any apartment building, even if it is built on the most modern technologies, the structural elements of the floor, coming into contact with floors, walls, pipes for water supply and heating, become conductors of sounds and noises from steps, furniture being moved, falling objects. Any room of the apartment, be it a bedroom, nursery, home cinema, living room or kitchen, must remain private to the owners and not create discomfort to the neighbors, and reliable insulation of the floor in it is one of the main conditions for ensuring comfort. To this end, between all the structural elements of the house and the floor lay a layer of sound-absorbing material, which suppresses noise and prevents their spread.

Content

Soundproofing Materials for Floor

Ways to soundproof the floor

Floating Concrete Coatings

Dry screed - floor insulation

Prefabricated floors - soundproofing option

The construction market offers a variety of natural and synthetic materials, which ensure good sound insulation of the floor and improve the acoustic characteristics of the room. Among the noise absorbing materials based on natural fibers the most popular are:

In addition to excellent sound insulation properties, all types of mineral construction wool are endowed with other important properties in construction:

The disadvantage of mineral wool is the thickness of the plates from 25 mm, and therefore, in cases when every centimeter of the height of the room is expensive, or for other technological reasons, good insulation of the floor in the apartment is provided with the help of synthetic roll materials such as:

The structure of sound-absorbing materials are:

The group of porous includes the most popular foam glass, aerated concrete, fibreboard, all types of construction wool. For sound insulation of floor structures, you should choose materials with a porosity of 80% and a pore diameter of not more than 1 mm.

Membrane materials are materials in which the reduction in sound power is achieved at the expense of energy consumption for overcoming forced vibrations. These are sheets of plywood, thick thick cardboard, soundproof fabrics.

In perforated materials, air-filled cavities and openings prevent sound from spreading. These include sheets of perforated plaster, asbestos cement, etc.

The most modern, efficient, environmentally friendly and easy-to-use way to reduce the level of noise in apartments and private residential buildings is the “floating floor” design.

It got its name because the floor construction of this type consists of several layers and not one of its elements comes in close contact with the surfaces of the floor and walls, and therefore does not extend to them and does not receive sound waves from them. There are three types of "floating floor":

This method is ideal for cases where, in addition to noise-absorbing properties, increased strength and high thermal insulation properties of the base and high thermal conductivity of the finishing floor covering are required, for example, when arranging a “warm floor”.

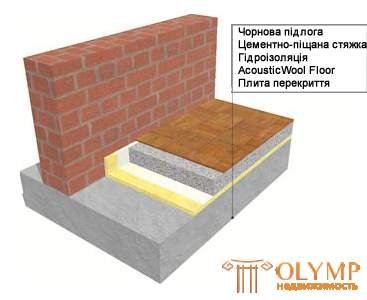

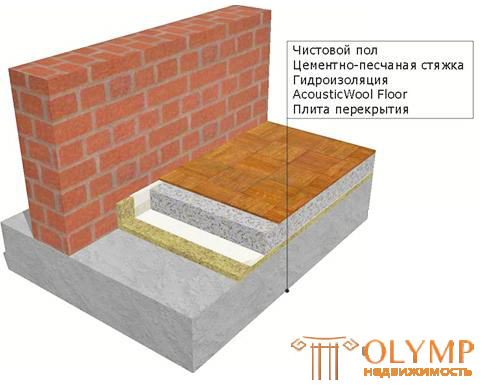

Laying a floating concrete floor, the overlapping concrete is covered with a layer of moisture-proof thick film, on which the insulation of the floor under the screed is laid, most often mineral wool. It is important that a layer of noise-absorbing material is placed not only on the concrete of the ceiling, but also along the contour of the room, laying an edgeband of it along the walls. Thus, the concrete screed seems to float or float independently of the base and walls. The width of the edge tape must be greater than the final height of the floor construction, and after the completion of work, its surplus is cut with a sharp knife.

Reinforcing metal mesh is placed on top of the insulating layer, lighthouses are placed and a concrete screed is poured over it.

Tip: In connection with the quick setting of the concrete mix, it is prepared in small portions and immediately poured, but in one room it is necessary to perform a screed in one day. In two or several receptions for several days, you can pour the screed in rooms with floor differences in height, while at the same time between the individual fragments of screeds leave temperature joints with a minimum width of 10 mm.

If on the surface of the base there are slopes and other flaws, it is equal with the help of a layer of fine expanded clay or sand. So that the floor does not subside with time, the filling is tamped to the maximum density.

Finishing flooring can be laid only after complete curing of the screed, that is, after 4-5 weeks. The design of a floating concrete field significantly increases the load on the ceiling, its thickness reduces the height of the room, and therefore its use is not always possible and appropriate.

Dry screed is an effective, fast and easy-to-perform way to create a “floating floor” and increase its noise-protective characteristics. Before you make noise insulation polapo this technology, it is necessary to choose the sound-absorbing material. Mineral wool slabs have the highest index of noise reduction from impacts: with a thickness of 20 mm, quench 46.5 dB.

A vapor barrier and a mineral wool material are laid on the concrete base, and a backfill is laid on top, having densely tamped down the layer and leveling it along the beacons. Along the perimeter of the room along the walls, an edge band of 20 mm thick sound insulation material is fixed, which is greater than the final thickness of the future floor construction. Surplus cut with a sharp knife after work.

On top of the backfill layer, gypsum-fiber plates are laid in two layers, ensuring that the gap between the wall and the slab is at least 10 mm. The plates of the second layer are laid with a shift relative to the first, so that their butt joints do not coincide. Gypsum fiber layers are glued together with glue of PVA, and then fastened with screws. The length of the screw should correspond to the thickness of the two layers of the coating so that it does not go beyond its limits.

This variant of sound insulation of floor structures is very popular, since installation is carried out without the use of concrete and “wet” stages, all the elements of the “puff cake” are involved in sound absorption, and you can lay the finish floor covering immediately after the last gypsum-fiber sheet has been laid. The thickness of the floor construction on a dry screed does not exceed 30-40 mm and almost does not reduce the height of the room.

This type of "floating floor" includes laminate, parquet, rabbeted solid wood and other similar coatings equipped with a tongue and groove system.

On a carefully prepared perfectly smooth base, the insulation of the floor under the laminate or parquet is first laid, and then the covering panels are mounted on it with a gap of at least 10 mm from the walls. Elastic foam polyethylene with a closed uniform cell system, polystyrene foam or cellulose sheet materials are used as sound insulation, but they provide a minimal sound-absorbing effect and play a greater role as a substrate.

To enhance the sound-insulating characteristics of a laminated or wooden floating floor, a cork substrate or a special Teksound sound-proof membrane is laid on the polymer layer, a layer of plywood is laid on it, and only after that the finish flooring is installed. The thickness of the sound insulation layer in such systems does not exceed 2-5 mm, which does not affect the height of the room.

Important: Regardless of the soundproofing method of the floor construction, the plinth should be attached to only one surface: either to the wall or to the floor, placing a cork or rubber gasket under it or into the gap between it and the wall. Nails are not recommended, as the metal is also a conductor of sound.

AcousticWool Glass Floor

Sound insulation for fiberglass based floor  Description

Description

Acousticwool Glass Floor plates are made from acoustic mineral wool based on staple fiberglass.

AcousticWool Glass Floor fiberglass-based soundproofing panels have a low dynamic modulus, which provides high insulation performance from impact noise.

Technical and acoustic characteristics

physical characteristics

|  |

Application area

Sound insulation plates are used for:

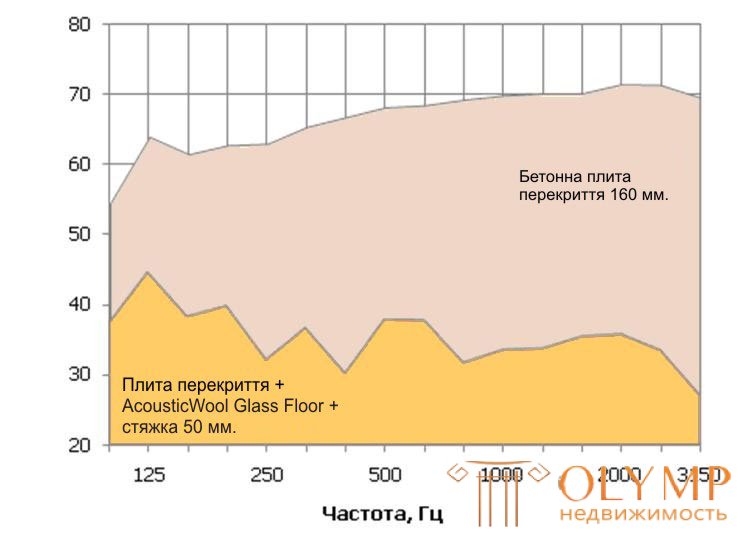

The use of sound insulation for the floor AcousticWool Glass Floor in the construction of a floating floor increases its sound insulation properties, which is confirmed by the results of tests in the laboratory of construction and architectural acoustics DNIBK (Kiev, Ukraine).

Certificates

AcousticWool Glass Floor certified in the UKRSEPRO system (Certificate of Conformity No. UA 1.052.0084445-09). Acoustic sound insulation for floor AcousticWool Glass Floor meets the requirements of SNiP II-12-77 "Protection against noise" and GOST 23499-79 "Materials and products building sound-absorbing and sound-proof. Classification and general technical requirements."

Acoustic Test Results

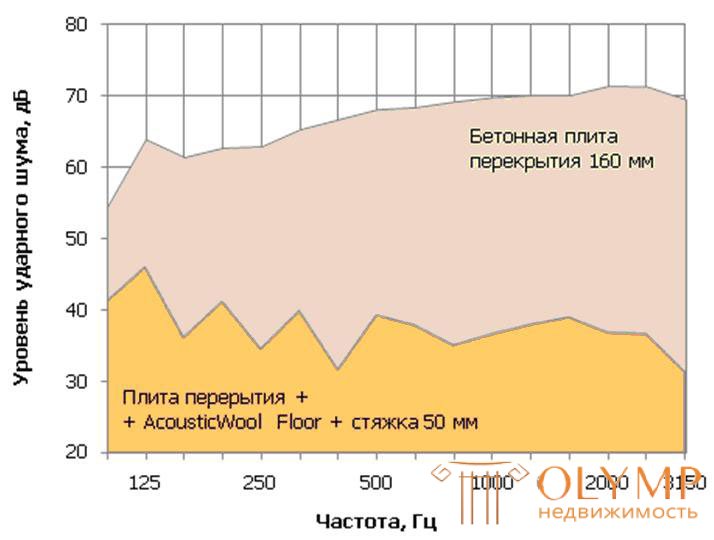

The frequency response of sound insulation from impact noise when establishing a floating floor using AcousticWool Glass Floor acoustic mineral wool:

Sound insulation of impact noise in the construction of "floating" floors using AcousticWool Glass

Acouflex

Soundproofing lining under floor coverings  Description

Description

Akuflex - soundproof lining, which meets the modern requirements of building acoustics.

Akuflex price 63.00 UAH / sq.m

Purpose

Akuflex is used in construction as a soundproofing lining for laminate, parquet and other flooring, to reduce the level of impact noise under the ceiling.

Composition

Polyester fiber, processed by a special technology for the acquisition of durable stable elastic properties.

Distinctive features:

physical characteristics

| Surface density | 300 g / m2 |

| Breaking load in length and width | not less than 750 N |

| Heat conductivity coefficient (λ), W / m ° С | 0.036 |

Packaging

| Roll width, mm | 1000 |

| Roll length, m | 15 |

| Thickness, mm (with a load of 1.8 kPa) | 3.8 |

| Roll weight, kg | 5.0 |

| Amount per pack m2 | 15 |

Impact noise reduction:

Shumanet 100

Rolled material for sound insulation shock noise  Description

Description

Shumanet 100 price is 155.00 UAH / sq.m

Shumanet 100 is a modern, high-performance material for reducing impact noise. The use of material Shumanet 100 guarantees the fulfillment of the requirements of SNiP-23-03-2003 in buildings of the category of comfort "B".

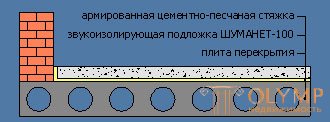

Application area

Shumanet-100 is used to reduce the level of impact floor noise, floor decks. The rolled material is intended for use as an elastic soundproofing substrate in the construction of a "floating floor" under a cement-sand reinforced screed.

Composition

Multi-layer soundproofing fiberglass Lb230, with a thin one-sided bitumen-polymer coating.

Distinctive features

physical characteristics

| Surface density, kg / m2 | 1,3 |

| Roll weight, kg | 19.5 |

| Waterproof under pressure of 0.49 MPa for two hours | water does not leak |

| Laying temperature | not below 0 ° C |

| Tensile strength along the web | not less than 170 N |

| Amount per pack m2 | 15 |

Roll size

Roll length: 15 m. Roll width: 1 m. Thickness: 3 mm

Acoustic tests were performed by the Acoustic Measurement Laboratory of NIISF RAACS, Moscow

| frequency Hz | 100 | 125 | 160 | 200 | 250 | 320 | 400 | 500 |

| Decrease in the reduced impact noise level ΔLn by a floating tie enclosed on a SHUMANET-100 layer (3 mm), dB | 3.0 | 4.0 | 3.5 | 2.5 | 2.5 | 11.5 | 16,0 | 11.5 |

| Frequency Hz | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3200 |

| Decrease in the reduced impact noise level ΔLn by a floating tie enclosed on a SHUMANET-100 layer (3 mm), dB | 16,0 | 21.0 | 20.0 | 29.0 | 34.5 | 37.5 | 43.0 | 48.0 |

The index of reducing the level of impact noise layer SCHUMANET-100 (3 mm): ΔLn, w = 24 db

Certificates

The material has acoustic and hygienic certificates.

Mounting technology

SCHUMANET-100 fits under the screed with fiberglass down, bitumen surface up. The roll is rolled on the surface of the floor slabs with an overlap of 20 mm, the joints are glued with tape. In order to avoid the collision of the concrete screed with the surface of the walls, the material SHUMANET-100 is put on the walls to a height slightly greater than the height of the screed. The screed must have a surface density of at least 100 kg / m2 and a thickness of 60 mm, and must also be reinforced.

Shumostop

Soundproofing plates for use in the construction of a "floating" floor

|

Description

SQUARE modern material with high sound insulation characteristics (ΔLn, w = 42 dB). Practically for any design of interfloor overlapping, the level of impact noise is 20 dB lower than that required by SNiP. When using Shumostop, one can speak of acoustic comfort, when the sound of a blow from a bottle that fell on the floor, in the room above, is perceived in the room below as a drop of a light coin.

Shumostop price is 129.00 UAH / sq.m

Application area

Shumostop is used as an elastic sound-proof layer in building structures under a reinforcing screed where a high level of sound insulation of impact noise is needed. The Shumostop-C2 plates act as the main working layer, and the Shumostop-K2 plates with a higher density perform the function of the edge layer to increase the stability of the floor around the walls.

Distinctive features

physical characteristics

| Shumostop-C2 | Shumostop-K2 | |

| Sizes of a plate, mm | 1250x600x20 | 1200x300x20 |

| Density, kg / m3 | 60 | 90-100 |

| Package weight, kg | 9 | 7.2 |

| Packing volume, m3 | 0.15 | 0.072 |

| Number of plates per package | ten | ten |

| Packing quantity, m2 | 7.5 | 3.6 |

Impact Sound Insulation

Acoustic tests were performed by the Acoustic Measurement Laboratory of NIISF RAACS, Moscow.

| frequency Hz | 100 | 125 | 160 | 200 | 250 | 320 | 400 | 500 |

| Reducing the reduced level of impact noise ΔLn floating tie, laid on one layer SHUMOSTOP, dB | 3.0 | 4.0 | 3.5 | 2.5 | 2.5 | 11.5 | 16,0 | 11.5 |

| Frequency Hz | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3200 |

| Reducing the reduced level of impact noise ΔLn floating tie, laid on one layer SHUMOSTOP, dB | 16,0 | 21.0 | 20.0 | 29.0 | 34.5 | 37.5 | 43.0 | 48.0 |

The impact noise reduction index ΔLn, w with one layer Shumostop = 42 dB , two layers Shumostop = 46 dB

The technology of laying the floating floor on the plates SHUMOSTOP

1. Surface preparation. The basis for the construction of a floating floor can serve as a reinforced concrete floor, and the existing screed. The surface of the floor is cleaned from debris. In the presence of the old flooring it is removed, which allows you to save the height of the room. The floor must be even, the height difference is no more than 1-2 cm over the entire area of the room. If necessary, a concrete concrete collection is carried out as a leveling layer.

1. Surface preparation. The basis for the construction of a floating floor can serve as a reinforced concrete floor, and the existing screed. The surface of the floor is cleaned from debris. In the presence of the old flooring it is removed, which allows you to save the height of the room. The floor must be even, the height difference is no more than 1-2 cm over the entire area of the room. If necessary, a concrete concrete collection is carried out as a leveling layer.

2. Laying soundproofing plates Shumostop. Soundproofing plates “Shumostop” are placed on the floor surface in 2 layers, butt joints so as to completely cover the floor area. To ensure the stability of the screed, high-density plates Shumostop-K2 with a strip of 300 mm are used around the perimeter of the room, the rest of the floor area is filled with plates Shumostop-C2. In order to avoid hard contact between the screed and the side surfaces of the room, the plates Shumostop-K2 150 mm wide are additionally installed along the walls in a vertical position. The second layer of the Shumostop plates is laid with regard to the overlap of the joints of the upper and lower layers. At the same time, the edge plate Shumostop-K2 of the upper layer has a width of 250 mm.

2. Laying soundproofing plates Shumostop. Soundproofing plates “Shumostop” are placed on the floor surface in 2 layers, butt joints so as to completely cover the floor area. To ensure the stability of the screed, high-density plates Shumostop-K2 with a strip of 300 mm are used around the perimeter of the room, the rest of the floor area is filled with plates Shumostop-C2. In order to avoid hard contact between the screed and the side surfaces of the room, the plates Shumostop-K2 150 mm wide are additionally installed along the walls in a vertical position. The second layer of the Shumostop plates is laid with regard to the overlap of the joints of the upper and lower layers. At the same time, the edge plate Shumostop-K2 of the upper layer has a width of 250 mm.

3. Laying communications. In order to avoid the formation of “acoustic bridges”, the heating pipes are wrapped with a Vibrostek-v300 vibration isolating tape (or equivalent). Electrical cables and other communications can be “hidden” in the thick sound-insulating slabs in the lower layer. This allows not to carry out additional work on the laying of cables on the walls and corners of the room.

3. Laying communications. In order to avoid the formation of “acoustic bridges”, the heating pipes are wrapped with a Vibrostek-v300 vibration isolating tape (or equivalent). Electrical cables and other communications can be “hidden” in the thick sound-insulating slabs in the lower layer. This allows not to carry out additional work on the laying of cables on the walls and corners of the room.

4. Waterproofing. On top of a layer of soundproofing plates, Shumostop consists of a 200-micron-thick reinforced plastic film with edges placed on the walls. This is necessary so that at the conclusion of the screed the plates do not get wet and do not lose their acoustic and mechanical properties. The edges of the film should be turned on each other with an overlap of 50 mm, and the joint should be glued with construction tape 50 mm wide.

4. Waterproofing. On top of a layer of soundproofing plates, Shumostop consists of a 200-micron-thick reinforced plastic film with edges placed on the walls. This is necessary so that at the conclusion of the screed the plates do not get wet and do not lose their acoustic and mechanical properties. The edges of the film should be turned on each other with an overlap of 50 mm, and the joint should be glued with construction tape 50 mm wide.

5. Device screed. A cement-sand screed of the M-300 grade with a thickness of at least 70 mm is being carried out. When constructing a tie, it is necessary to reinforce it with a metal grid with a mesh size of 50x50 mm and a bar diameter of 4 mm. The grid should be located in the screed layer not lower than 20 mm from its lower level and not higher than the middle line of the screed. The grid is laid out of the overlap joints that are connected by a knitting wire. The mixture M-300 is poured with water and brought to the "semi-dry" state, and then distributed over the entire surface of the floor evenly. The surface of the mortar is leveled with a slat. The freshly laid on the mark screed overwrites for additional finishing alignment and strengthen the top layer to obtain a completely flat surface. A day after the end of the work, the screed spills with water and is covered with plastic wrap for a period of 2 weeks. During this period, the room should be well ventilated.

5. Device screed. A cement-sand screed of the M-300 grade with a thickness of at least 70 mm is being carried out. When constructing a tie, it is necessary to reinforce it with a metal grid with a mesh size of 50x50 mm and a bar diameter of 4 mm. The grid should be located in the screed layer not lower than 20 mm from its lower level and not higher than the middle line of the screed. The grid is laid out of the overlap joints that are connected by a knitting wire. The mixture M-300 is poured with water and brought to the "semi-dry" state, and then distributed over the entire surface of the floor evenly. The surface of the mortar is leveled with a slat. The freshly laid on the mark screed overwrites for additional finishing alignment and strengthen the top layer to obtain a completely flat surface. A day after the end of the work, the screed spills with water and is covered with plastic wrap for a period of 2 weeks. During this period, the room should be well ventilated.

6. Finishing flooring. After complete drying of the screed (about 3 weeks), the polyethylene reinforced film, as well as the excess edge plate, Shumostop-k2, is cut to the level of the finished floor. The gaps are treated with Vibrosil silicone acoustic sealants. Ready smooth and strong surface of the floating floor can serve as the basis for any type of floor covering. Parquet, laminate, parquet, linoleum, carpet or ceramic tile can be used as a topcoat. The plinth is attached to only one of the surfaces: to the floor or wall.

6. Finishing flooring. After complete drying of the screed (about 3 weeks), the polyethylene reinforced film, as well as the excess edge plate, Shumostop-k2, is cut to the level of the finished floor. The gaps are treated with Vibrosil silicone acoustic sealants. Ready smooth and strong surface of the floating floor can serve as the basis for any type of floor covering. Parquet, laminate, parquet, linoleum, carpet or ceramic tile can be used as a topcoat. The plinth is attached to only one of the surfaces: to the floor or wall.

Distinctive design features of the floating floor Shumostop

AcousticWool Floor

Sound insulation material based on basalt fibers  Description

Description

AcousticWool Floor - rigid hydrophobized plates made of acoustic mineral wool based on basalt rocks.

AcousticWool Floor soundproofing plates have lower dynamic stiffness compared to other basalt slabs of the same density, which provides improved sound insulation characteristics.

Technical and acoustic characteristics

physical characteristics

|  |

Application area

Sound insulation material is used for:

The use of acoustic mineral wool AcousticWool Floor in the construction of a floating floor increases their sound insulation properties, which is confirmed by the results of tests in the laboratory of construction and architectural acoustics DNIBK (Kiev, Ukraine).

Certificates

Sound insulation for the floor AcousticWool Floor is certified in the UKRSEPRO system (Certificate of Conformity No. UA 1.052.0084445-09). Acoustic mineral wool Acousticwool Floor characteristics meet the requirements of SNiP II-12-77 "Protection against noise" and GOST 23499-79 "Sound-absorbing and sound-proof building materials and products. Classification and general technical requirements."

Acoustic Characteristics

The frequency response of the sound insulation of impact noise when installing a floating floor with the use of sound insulation plates AcousticWool Floor *

Что бы оставить комментарий войдите

Комментарии (0)