The wall is a vertical enclosing structure that separates the room from the surrounding space or the next room.

The wall of the building is the bearing and (or) enclosing element of the building. Structurally, external walls can be single-layered or complex structures.

An important part of the wall construction is shrink seams.

Requirements for the walls. The classification of the walls .

Primary requirements:

1. strength and stability;

2. must provide the premises with the necessary temperature and humidity conditions;

3. must have sound-proofing properties (depending on the purpose of the room);

4. fire resistance (depending on the fire resistance of the building);

5. industrialness.

In addition, the walls should have a minimum weight, the lowest cost and constructed whenever possible from local materials.

By the nature of the material, walls are distinguished: stone, wood, and walls made of other materials, including synthetic (as an experiment).

Stone subdivided into :

1. masonry walls;

2. monolithic;

3. large-panel walls.

The masonry walls are made of artificial or natural stones, the seams between which are filled with mortar.

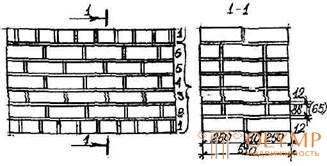

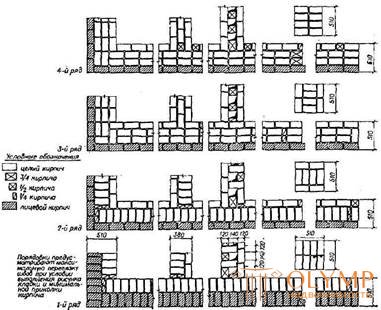

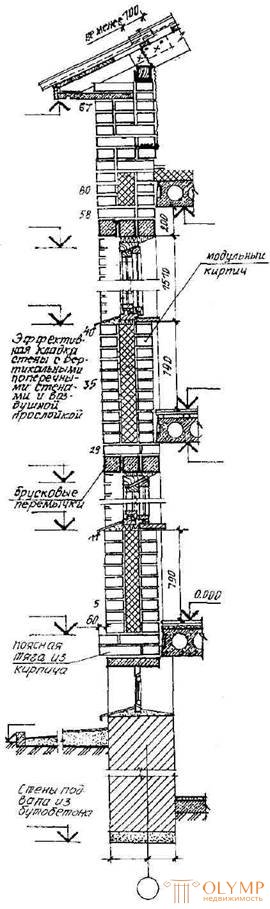

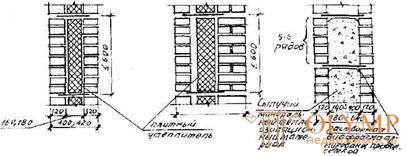

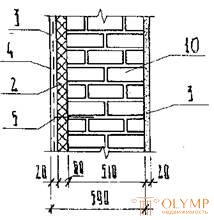

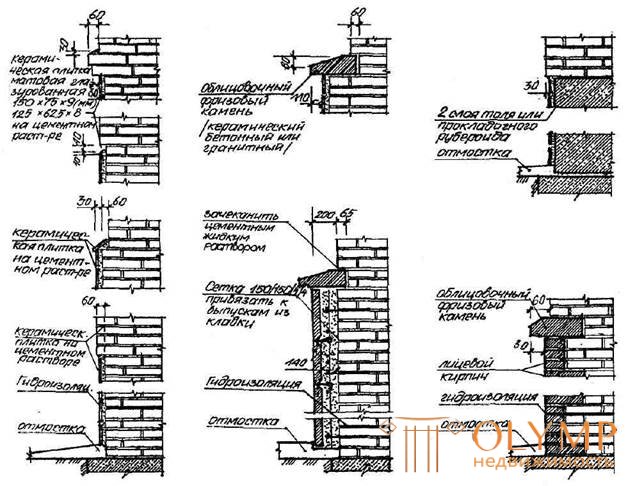

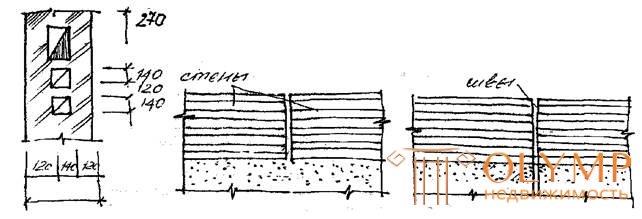

Brick walls, by their structure, are divided into:

1. homogeneous walls made of ordinary bricks or light construction bricks;

2. lightweight and non-uniform walls in which part of the brickwork is replaced with other materials or an air layer (Fig. 27.).

The most common brick is ordinary (full-bodied) or silicate. The thickness of the homogeneous walls is a multiple of 1/2 of the brick:

½ brick - 120 mm;

1 ½ bricks - 380 mm;

2 bricks - 510 mm;

2 ½ bricks - 640 mm

3 bricks - 770mm; etc. (half-brick - 120 mm + seam (10 mm) = 130 mm).

The thickness of a horizontal seam is 1.2 cm - with this, 13 rows of brick laying are 1 m.

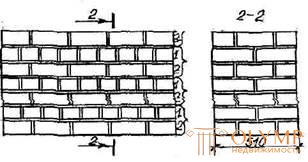

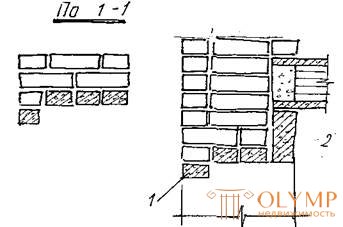

In construction practice, 2 types of dressings are predominantly used (from a larger number): chain (two-row) and spoon (multi-row) (Fig. 27.).

In buildings over 7 floors, in the corners and intersections of the outer and inner walls, steel anchor ties are installed. They must enter into each of the adjacent walls at least 1m.

In low-rise buildings, as well as in the upper floors of multi-storey buildings, hollow and lightweight (porous) brick or lightweight masonry should be used for laying exterior walls.

The most common types of lightweight brick walls:

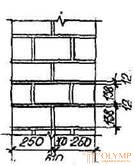

Brick walls

Solid horizontal rows give strength to the wall, but worsen its thermal performance (cold bridges). Apply - with a height of no more than 2 floors (Fig. 29.30.).

Brick and concrete walls

The advantage is that the adhesion of concrete with masonry provides a more reliable connection between the brick walls and, moreover, concrete perceives part of the load.

The disadvantage - a large amount of moisture - slows drying, increased complexity and difficulty in the production of works in the winter (Fig. 31)

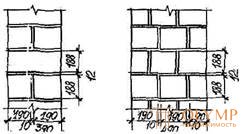

Thermal break walls

The connection between the walls - through 3-5 rows - steel brackets (from strips) or knotted masonry rows.

Thermowells - foam concrete, foam silicate, xylolitosilicate, etc. The advantage is less moisture and the possibility of working in the winter.

Well Walls

Wells are filled with backfilling, light concrete, or lightweight concrete liners. Horizontal precipitations are provided from precipitation through 400, 500 in height from the brickwork solution (Fig. 31.).

Brick walls with insulation from insulation boards or panels

Plates are attached to the brickwork with wire straps. With this solution, there is no need to do plaster. New technical solutions to the walls of civilian buildings, allowing to increase the resistance to heat transfer due to their insulation by thermal insulation materials used in recent years in Ukraine. Example: solutions of enclosing structures with insulators manufactured by ISOVER (Fig. 32.).

Walls with air gap

When a closed air gap remains in the masonry, due to the expanded seam, the thickness is up to 50 mm. This saves bricks, mortar and reduces the thickness and weight of the wall. Bonder rows every 6 spoon (Fig. 31.).

Walls of ceramic stones (seven chisel)

They are made with a thickness of 1 ½, 2 bricks or 2 ½ bricks. They are laid by buttings (slots perpendicular to the heat flow) - hence the chain clutch (Fig. 27.).

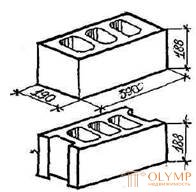

The walls of small lightweight concrete stones

Compared to brick - the same thermal performance with a smaller thickness, but less strength (Fig. 27, 33, 34.).

Walls of natural stones

It is rational only if there are rocks with a porous structure in the construction area that are sufficiently strong and easily processed.

Limestones - shell rock (northern Black Sea coast), Inkerman limestone (Crimea).

Laying: chain and trehradnaya spoon. Walls do not require exterior plaster.

Stone houses are gradually giving way to semisibalon buildings, but still remain one of the most common types of multi-storey buildings, contributing to the diversity of urban development.

Stone materials with a large bulk density, have a high thermal conductivity, and therefore for technical reasons they have to arrange a considerable thickness - from 38 to 77 cm, which causes an increase in the weight, cost and labor intensity of buildings. The strength of the same mossy stone walls in the upper floors is not used.

The thickness of the walls in the lower floors of houses above 6 floors is increased to increase their bearing capacity, and in some cases, for this purpose, special local wall thickenings (pilasters) or reinforced concrete columns working in conjunction with the stone wall are arranged in the lower floors.

Increasing the load-bearing capacity of stone walls and pillars can be achieved by using high-strength materials (brick 150-200 with M100 mortar) in the lower floors or by reinforcing masonry joints with horizontal grids of wire with a diameter of 4-5 mm.

Wooden walls

At present, there are three systems of typical wooden houses - block-shaped, frame-type and panel board (Fig. З5, 36, 37).

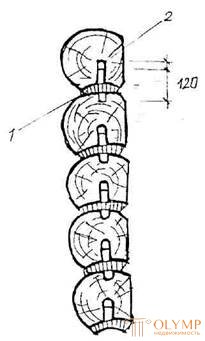

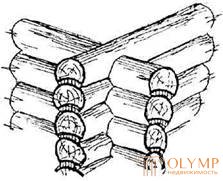

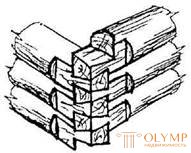

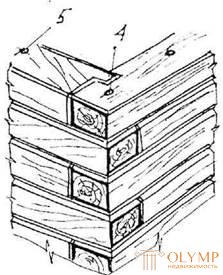

The basis of the walls of log houses are log houses made of round logs with a diameter of 180-240 mm, with each log grooved from the underside, placed on the round surface of the previous log (hump). With the laying of a layer of tow of linen or hemp tow or moss. A log is called a rectangular volume, composed of crowns, connected at an angle by cuts; crown called a series of logs laid on the perimeter of the building. The main types of construction of the corner joint of logs are cuttings with a residue (into a cup) and without residue (into a paw) (Fig.35).

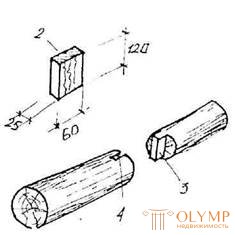

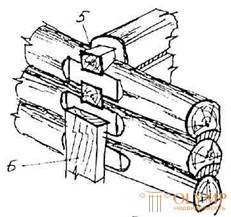

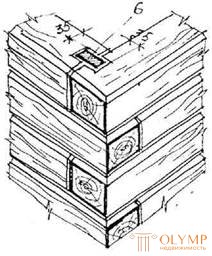

The walls of the block houses are made of bars, i.e. logs hemmed on four edges. The thickness of the bars 180 and 150 mm satisfies the climatic conditions of areas with the estimated t ° of outside air not lower than -30 ° C. Log walls in these conditions would have to have a diameter of 200mm. At t ° = - 40 ° С - brick wall 180mm, and log 220 - 240mm. Bars are interconnected on pins (spikes), and the corners and mates with the inner walls are assembled using mating into a tongue or into a paw. Between the bars stack tow. After mounting the walls, the grooves are pierced. The ends of the floor beams are placed in the appropriate row of bars and fastened with spikes or hem

"Dovetail" (Fig. 36.).

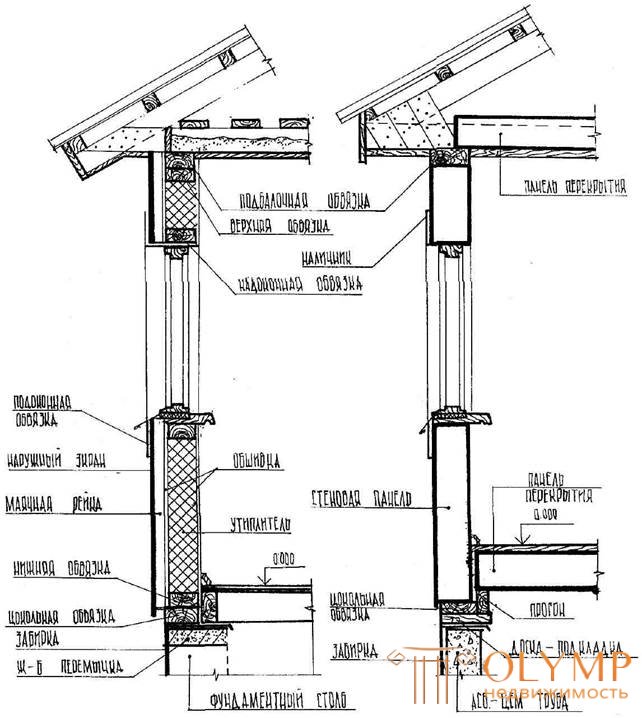

Prefab houses

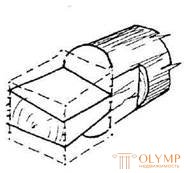

Frame houses are more progressive than cobbled ones, as require less wood consumption. Their supporting structure is a wooden frame, consisting of racks, with a section of 50 * 80mm, horizontal elements of the same section. Racks are installed with a modular pitch of 600mm in the axes and nailed to the lower and upper straps (Fig. 37.).

Prefab panel houses .

The boards of the outer and inner walls usually consist of two layers of boards with a thickness of 16 mm, between which insulation in the outer walls is laid several layers of fibreboard insulation (porous) plates (Fig. 37.).

Ground walls

Porous rocks with low volumetric weight and easily machinable.

Walls of soil materials are usually built from molded blocks, called soil blocks. These include raw and saman - raw stone (made from oily clay with the addition of organic fibrous material) dried in the sun (Fig. 38.).

Lime, resin or bitumen is used as stabilizing additives. Such soil blocks are called terranite .

- dried ground blocks - sediment 1 -2%;

- poorly dried soil blocks - sediment 4-5%;

The laying of blocks with a thickness of 3/2 of a stone of soil blocks with limited additives have dimensions of 390 * 190 * 140mm; 330 * 185 * 120mm.

Minimum wall thickness 50 cm.

The sediment of clay walls is 15-18% and can last up to 2 years.

Soil materials include materials used for insulating load-bearing walls - these are reed plates 50–100 mm thick made of reed stems, connected by wire; somolite - from bundles of straw, connected by wire, like reed, strol, i.e. hot-pressed plates made from straw or other vegetable fiber, paper-covered, porous fiberboard with a thickness of 12-16mm, peat from peaty fiber (peat moss) with the addition of bituminous substances or honeycomb plates with the addition of synthetic materials.

Surface finish of stone walls.

When laying brick exterior walls of buildings of class II, the seams on the facades are embroidered with smoothing with ordinary or colored mortar on white cement, giving the profile a roller or groove.

Facade plastering is permitted only in cases where the walls are made of low-strength, crumbling stones or bricks of insufficient quality. In some cases, the construction of public buildings used finishing facades rustication.

In the construction of public buildings of I and II class, cladding made of ceramic materials in the form of large cladding tiles, laid with the use of laying rows using anchor brackets is used. Sometimes used wall cladding sheets of asbofanera, tempered glass, corrugated metal or fiberglass. Large-size facing plates from valuable breeds of a natural stone or color weatherproof concrete are hung on a wall.

Walls of sawn natural stone are trimmed with a notch or rubbing the front surface with steel brushes, giving light vertical scars, which improve water flow.

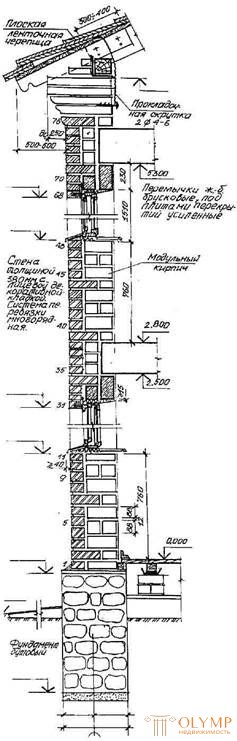

Architectural and structural elements and details of the walls.

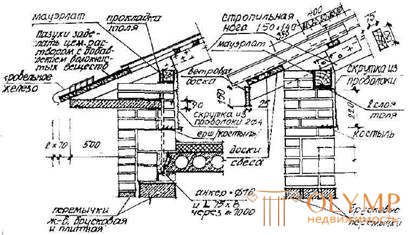

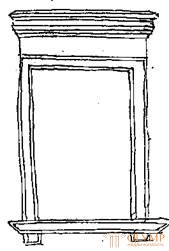

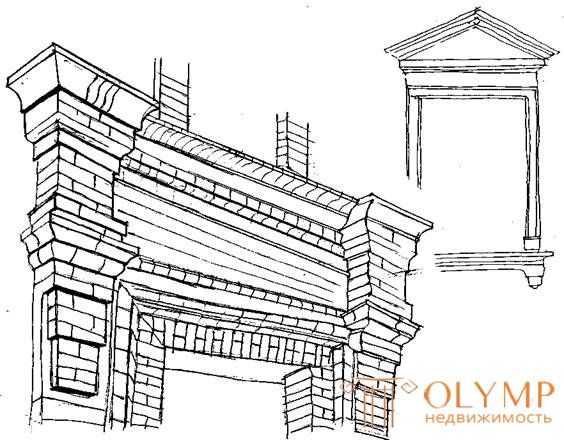

Eaves called horizontal profiled protrusions of the walls. Cornice, located on top of the wall, called crowning, or main. The size of the ledge of the eaves for the surface of the wall is called the removal of the eaves, or eaves overhang. In addition to the crowning cornice, intermediate cornices can be arranged that have smaller take-off and are usually located at the levels of some interfloor overlappings, and sometimes under window openings. In the latter case, they have even less removal and are called corbel.

Sometimes arrange separate eaves above the openings. Such cornices are called sandriks . Eaves and sandrik in recent years, as a rule, perform of the assembly blocks. Eaves divert rainwater and melt water from the walls and thus protect them from moisture (Fig. 39).

Sometimes the wall of a building is led out somewhat higher than the crowning eaves, forming the so-called parapet. Parapet replaces fencing (railing).

When going from a greater thickness to a smaller one, the walls of the walls are called edges, which are usually arranged from the inside at the level of the floors between the floors.

The stability of brick walls of great length and height is provided by the device of narrow vertical thickenings, called pilasters. Pilasters are expedient, in particular, in places where the flooring or covering elements are supported on the walls (Fig. 39).

The gable is the front side (completion of the facade of the building, portico, colonnade).

Buttresses are called pilasters, the thickness of which increases from top to bottom, as a result of which their outer face is oblique. Sometimes part of the wall comes forward relative to the rest of the plane, forming a protrusion outward. Such a thickening is called straightening. The large ledge of the wall, which increases the size of the room, is called risalit (Fig. 39.).

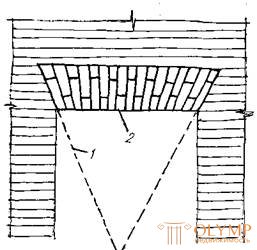

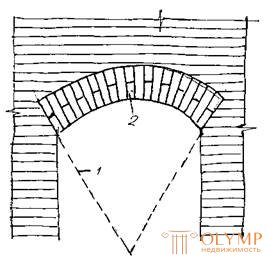

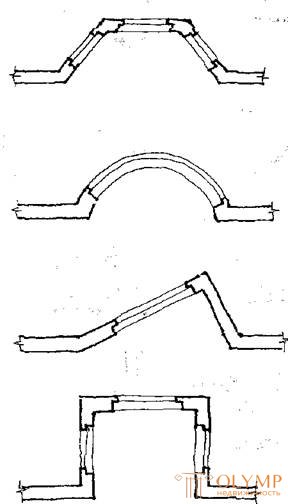

Jumper over openings.

The apertures are covered with bridges, which perceive the load of the overlying masonry, and sometimes of the floors, and transfer it to the pier walls. Previously, when erecting stone walls, wedge, flat and arched lintels were used (fig. 39, 40, 41.).

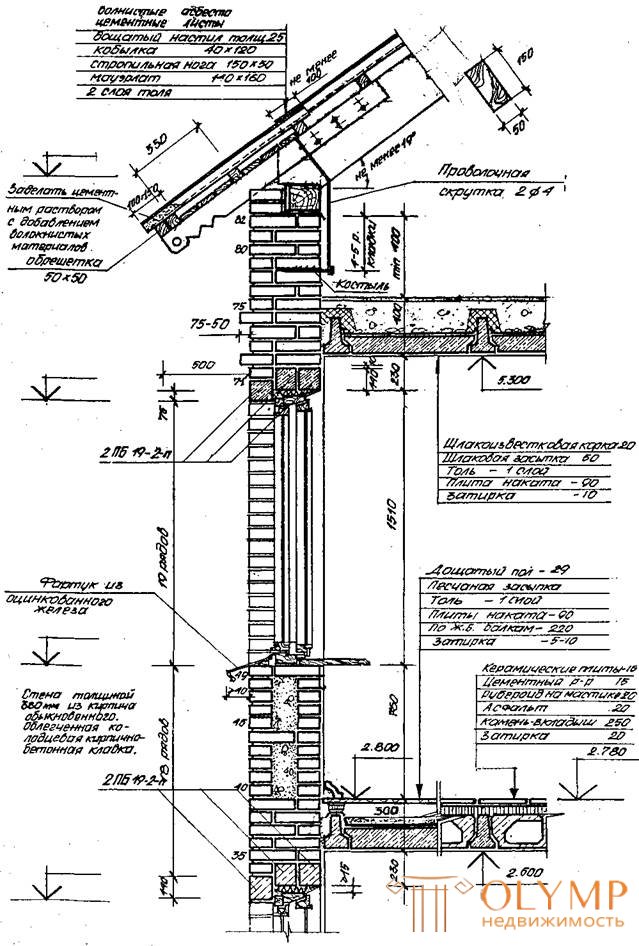

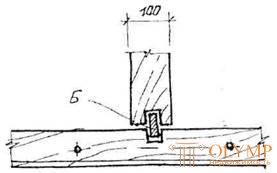

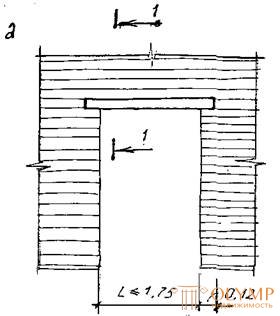

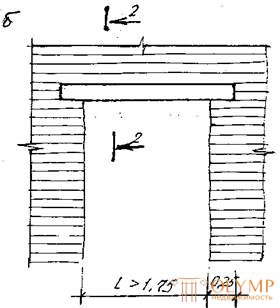

Bar lintels are used to block openings in self-supporting walls up to 2.25 m wide, they are made of precast reinforced concrete bars with a cross-section equal to the cross-section of a brick taking into account mortar seam 120x175 and 120x150 mm.

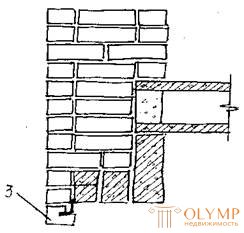

With a width of openings in self-supporting walls of more than 2.25 m, precast reinforced concrete lintels are used with a cross-section that is a multiple of the cross-section of a brick 120x220, 120x300mm (fig. 29, 31, 33, 40.).

In the absence of standard reinforced concrete bars, openings with a width of up to 2 m are covered with ordinary bridges. For their device, reinforcement from round steel d = 6mm or strip rolled steel is laid under the bottom row of bricks.

For openings with a width of more than 2 m or under heavy loads, sometimes armor bridges are used , which differ from the ordinary ones in that in vertical longitudinal joints of the masonry above the openings lay frames made of round steel.

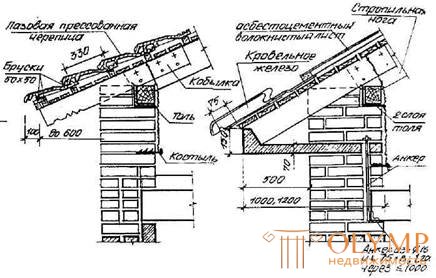

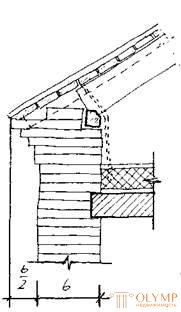

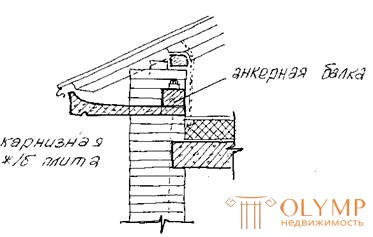

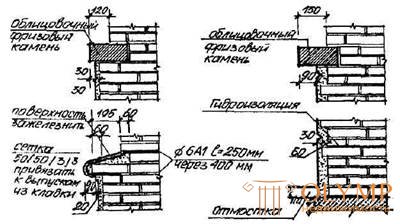

Eaves.

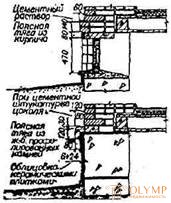

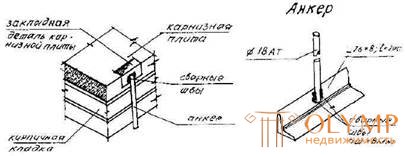

The crowning cornice of the brickwork of the wall with its small removal (up to 30 mm and not more than 1/2 of the wall thickness) can be laid out of brick by gradually removing the rows of masonry (60-80 mm in each row). With the removal of more than 300 mm, cornices are made from prefabricated reinforced concrete slabs that are cantilevered into the walls (Fig. 31, 33, 41.).

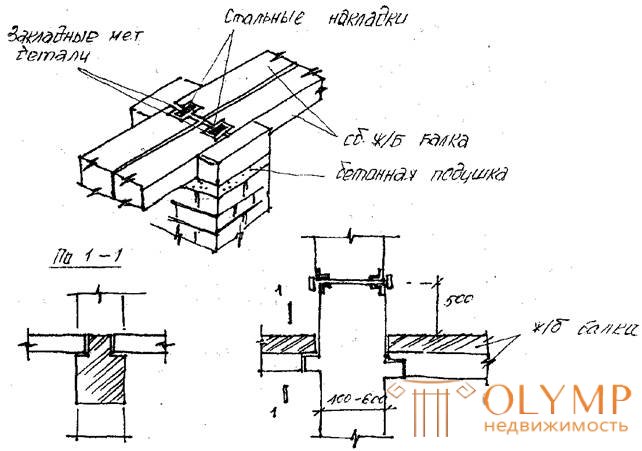

To ensure the stability of the eaves, the inner ends of reinforced concrete slabs are overlapped with longitudinal precast reinforced concrete beams, which are attached to the masonry using steel anchors embedded in it (Fig.41.).

The protection of the wall from wetting by rainwater is facilitated by the installation of window sills made of galvanized roofing steel, ceramic tiles or shaped elements made of synthetic materials.

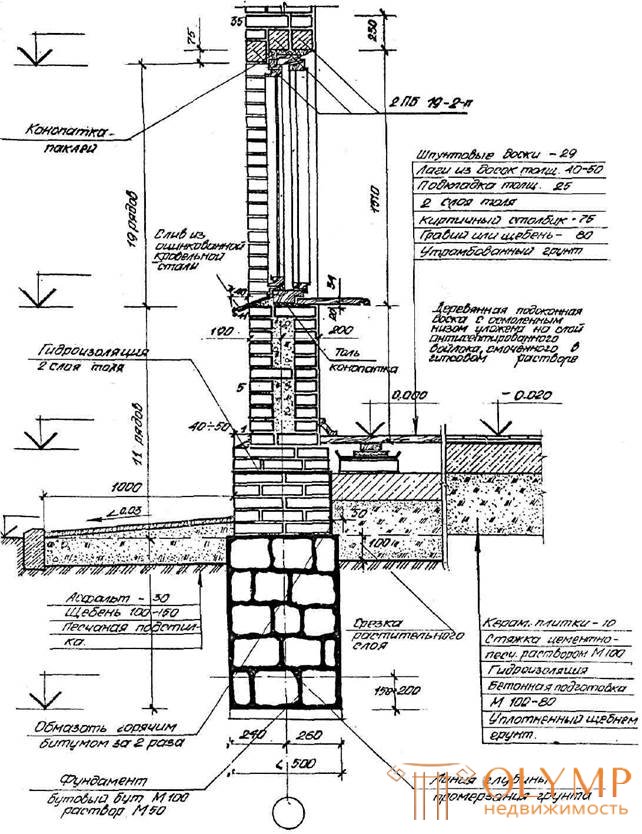

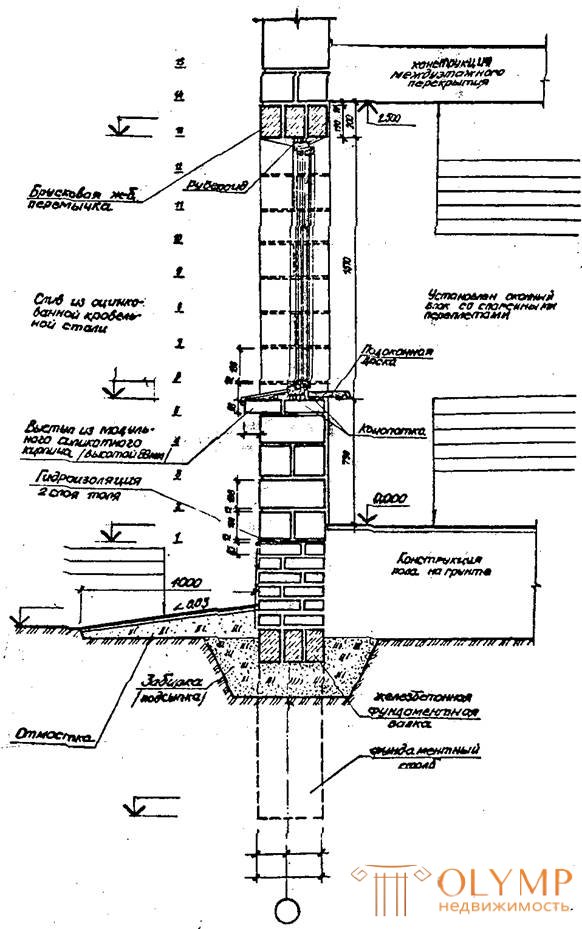

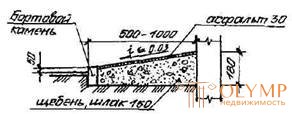

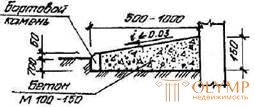

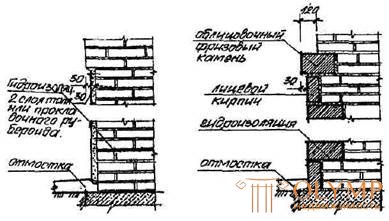

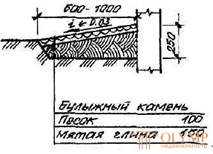

The basement of the wall.

Perform to protect its lower zone from rain and melt water, as well as from possible mechanical damage during operation of buildings. The basement is made of durable, waterproof, durable materials. The height of the basement is made at least 500 mm (Fig.42.).

The basement of the brick walls should be laid out of well-burnt clay ordinary brick. Silicate and lightweight bricks can be used for laying the basement just above the waterproofing layer provided that it is lined with ordinary clay bricks or other weather-resistant material, for example, reinforced concrete slabs.

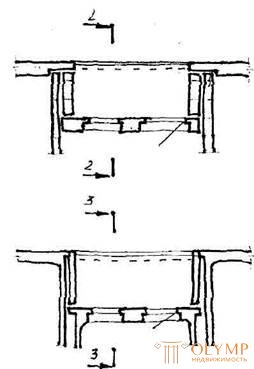

Chimneys and ventilation ducts.

Chimneys are located in the inner walls of buildings (Fig.42.).

In large-block and large-panel buildings for this purpose special blocks with vertical voids are provided. These walls adjoin bathrooms or kitchens. The walls are laid with channels on clay mortar from well-baked bricks.

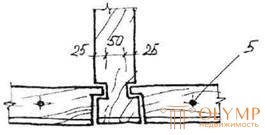

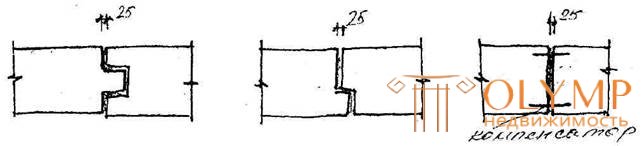

Expansion joints.

The seams are thermal and sedimentary (Fig.42.).

Temperature joints are performed in walls of great length in order to avoid the appearance of cracks due to temperature changes. The distance between them is from 25 to 200 mm, depending on the climate and the material of the walls.

Sedimentary seams are arranged:

1) at the boundaries of sites in different loads on the base;

2) at the boundaries of areas located on dissimilar soils;

3) on the borders of the plots with different sequence of development;

4) in all cases when it is possible to expect an uneven draft of adjacent areas of the building.

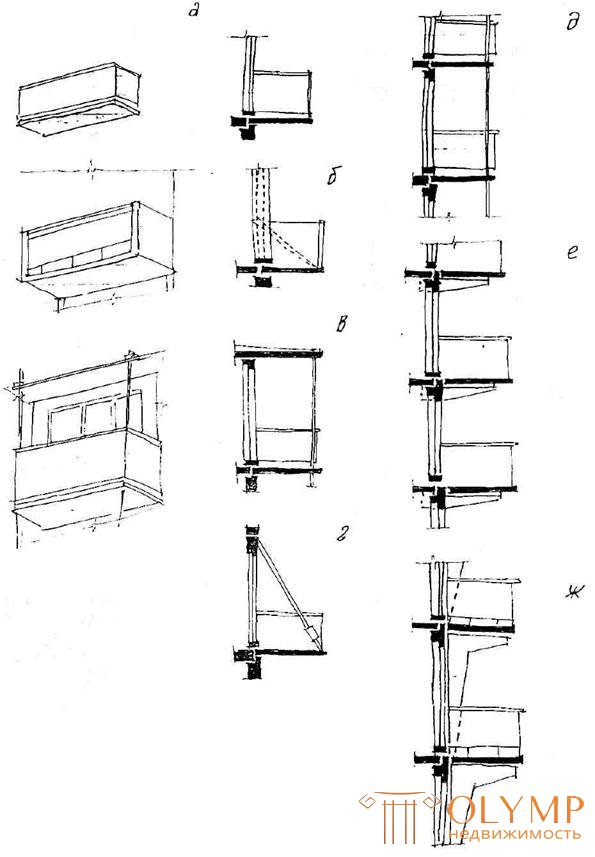

Constructions of balconies, bay windows and loggias.

Balcony is an open area with fences, rendered from the plane of the outer walls of the building. The composition of the main elements of the balcony: base plate, floor design and fencing (Fig.43.).

In buildings with bearing outer stone walls, balconies are arranged in the form of a cantilever reinforced concrete slab, securely clamped by an overlying wall, in the form of a slab laid on reinforced concrete consoles or brackets. Balcony plates, brackets and brackets must be anchored before installing the overlying wall.

In frame buildings, the rear edge of the balcony slab is supported on an external self-supporting wall for minimum depth, and the front one - on load-bearing racks or, alternatively, on load-bearing strands (cables or rods) made of stainless steel.

In frame buildings with transverse load-bearing walls of the structure in the form of standing "shelves" consisting of a series of balcony plates, supported by the rear edge of the transverse walls or columns, and the front on the rack.

In balconies used in buildings with a narrow pitch of supporting structures, balcony plates can be supported by cantilever railings opposed to supporting structures.

Balcony fences are made of metal gratings, the racks of which are buried in balcony plates, of flat asbestos-cement or fiber plastics, of colored reinforced glass and other materials (Fig. 45, 46.).

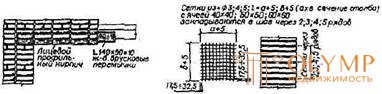

Individual supports

Каменные столбы, применяют в качестве промежуточных опор в

малоэтажных зданиях. Их возводят из сплошного полнотелого кирпича

или камня (рис.42.).

Сечение не менее 380x380мм (1,5x1,5 кирпича) с обязательной

перевязкой швов каждого ряда. Для увеличения несущей способности

столбов применяют, материалы (кирпич марок 150-200 на растворе М100)

повышенной прочности и вводят армирование кладки горизонтальными

стальными сетками из стержней 4-5мм с ячейками 100-150 мм, располагаемыми в горизонтальных швах через 2-4 ряда кладки. Таким образом, несущая способность повышается в 1,5 раза.

Каменные столбы часто заменяют сборными железобетонными или

монолитными колоннами. Фундаменты под каменные стены столбчатые,

бутобетонные (рис. 42.).

Неполный каркас с каменными столбами применяется в зданиях высотой до 9 этажей. В более высоких зданиях - внутренние опоры (колонны) устраиваются из железобетона или металла.

Железобетонные колонны двухконсольные располагают по средним и крайним рядам при применении навесных панелей наружных стен.

Колонны сечением 300x300 мм применяются для зданий высотой до 5 этажей; колонны сечением 400x400 мм - для всех остальных случаев.

Стыки колонн по высоте осуществляют со сваркой закладных металлических деталей и омоноличиванием узла сопряжения.

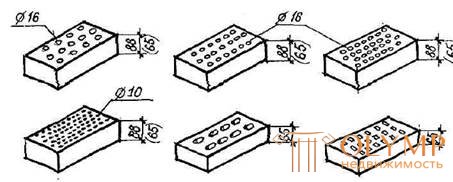

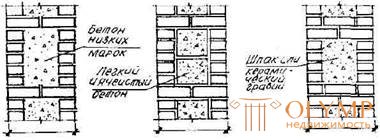

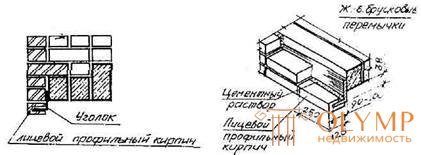

МАТЕРИАЛЫ И ТИПЫ СПЛОШНЫХ КЛАДОК

НАРУЖНЫХ КАМЕННЫХ СТЕН

КИРПИЧ СПЛОШНОЙ

EMPTY BLUE BRICK

(modular - 88, solid - 65)

CERAMIC STONES

Lightweight concrete

WITH CRITICAL VOLUMES

(WHOLE AND HALF)

THREE-POWERED

(PECULAR AND FALSE)

BRUSHED SHELF

BRICK TABLE DOUBLE-GRADE

LAYER FROM CERAMIC STONES

MELTING FROM CONCRETE AND NATURAL STONES

LAYER FROM CONCRETE STONES WITH BRICK FIRMING

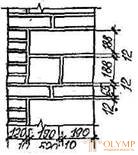

Fig. 27.

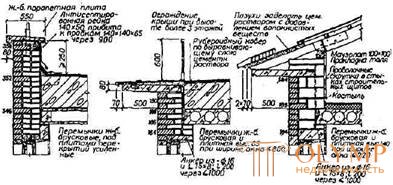

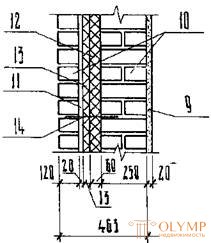

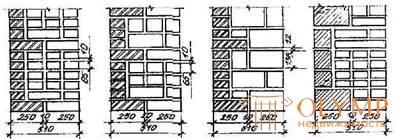

CARRYING BRICKED WALLS OF CONTINUOUS LAYER FOR BUILDINGS ARE UP TO 14 FLOORS (ON SERIES 2.130-1)

ORDER WALL ORDER WITH FACIAL DECORATIVE WAY.

MULTI-ORDER LINK SYSTEM

VARIANTS OF PARAPETS AND EARNINGS WITH LONG-TERM AND TRANSVERSE CARRIER WALLS

VARIANTS OF DECORATIVE FACADES AND FACADES OF MULTI-ORDER AND CHAIN WALLS

LINING FACING

REINFORCING A BRICK POST

EXTERNAL WALL ORDER PLANS WITH FACIAL DECORATORY WALL (MULTI-TRUNK BANDING SYSTEM) AND BRICK POST SECTION 510 × 510

OPTIONS OF THE SCHOOL

WALL ANGLE

COUPLING WITH INTERNAL WALL

PLOT SPACE

WITH QUARTER

QUARTER TO

NO CHANNELS

WITH CHANNELS

Fig. 28

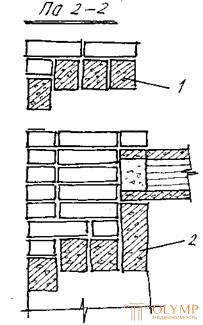

Fig. 29.

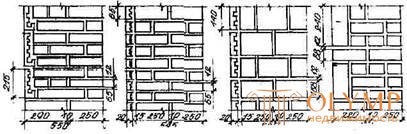

ORDER WALL EFFECTIVE ORDER

BRICK-CONCRETE LAYER

Fig. thirty.

ORDER WALL ORDER

EARNINGS OPTIONS

FIXING EARTHED PLATES

LIGHT (EFFICIENT) LINES

WELL-BRICK-CONCRETE

WITH HEAT INSERTS

WITH PLASTIC SLIM OR KERAMICH. Gravel

WITH VERTICAL HARDNESS DIAPHRAGMS

WITH PLATE HEATER AND AIR LAYER

SAME WITH ENHANCED INSIDE CARRIED LAYER

WELLS WITH WARMING FILLING AND HORIZONTAL REINFORCED DIAPHRAGMS

Fig. 31.

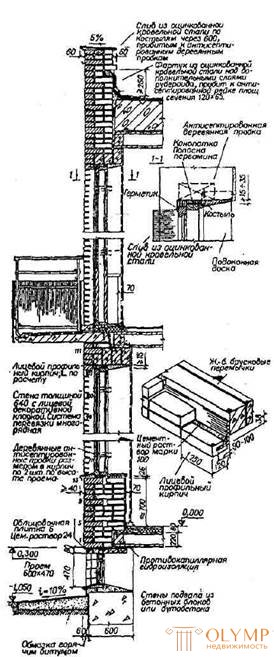

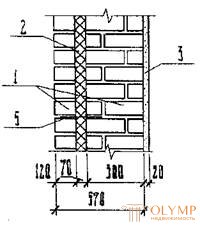

one.

silicate brick GOST 379-79 on cement - sand mortar, the thickness of the inner ball 380-510 mm;

2

ISOVER heat insulation plates of the brand OL - E or OL - A ДСТУ 8.2.7.- 38 - 96;

3

cement - sand plaster, thickness 20 mm;

four.

fiberglass ;

five.

metal bonds of galvanized steel Ø4Вр I through 0.5 m in length of the wall and through 5 rows in height;

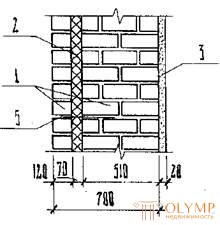

6

small concrete blocks GOST 6133-84

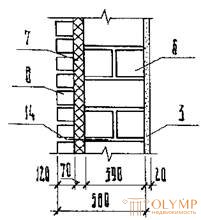

7

ISOVER heat insulation boards of К L or К L brand - А 70 mm thick;

eight.

ceramic hollow brick with a density of 1400 kg / m3 on cement-sand mortar brand M25;

9.

lime and sand plaster;

ten.

ordinary clay brick GOST 530-80 on cement-sand mortar brand M25;

eleven.

air gap 20 mm thick;

12.

ISOVER heat-insulating plates of the K L or K L brand —A — 60 mm thick DSTU 8.2.7. 56 - 96

13.

insulating plates with wind-proof lining ISOVER brand RKL - EJ 13 mm thick DSTU 8.2.7. 56–96;

14.

metal connections from galvanized steel Ø6 А I through 1000mm in length and through 600 mm in height

Fig. 32.

ORDER WALL ORDER

EARNINGS OPTIONS

LINING FACING

WALL OF EXTERNAL WALLS WITH FACING

FROM BRICKS TOGETHER WITH PERSONAL BRICK

FROM CERAMIC STONES AND PERSONAL BRICK

FROM BRICK AND FACIAL CERAMIC STONES

FROM BRICK WITH BENCHED FACING CERAMIC COOKERS

FROM BRICK AND CERAMIC PLATES

FACING WITH APPEARED CERAMIC PLATES ON SOLUTION

FROM A BRICK WITH FACING WITH FLAT PLATES (STONE, CONCRETE) WITH GASKETS FROM THE SAME PLATES

Fig. 33.

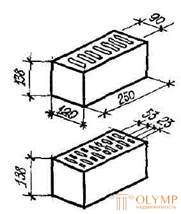

VERTICAL ORDER LAYS FROM LIGHT-CONCRETE STONES EXTERNAL WALL

Fig. 34

Details of log walls

Logging at height

Log lengthwise

1 - caulker; 2 - thorn; 3 - comb;

4 - groove; 5 - treatment of the end of the log

internal wall for interfacing

“In a pan”, “dovetail”.

DETAIL OF CONSTRUCTION OF THE END OF THE END OF THE END OF THE LOG FOR FOR STRESSING IN THE PAWN

ANGULAR REDUCTION "WITH REMAIN"

CUP "CUP"

ANGULAR JUMPING "WITHOUT RESIDUE"

Shirt "in the paw"

COUPLING OF INTERNAL AND EXTERNAL WALLS

Fig. 35

DETAILS OF CUTTED WALLED WALLS

CONSTRUCTION OF BARS AT HEIGHT

CONSTRUCTIONS OF EXTERNAL WALLS WITH INTERNAL WALLS

On spikes

ON THE RODS

IN THE CORNER ON THE SPIKES

ON THE RODS

1 - caulker; 2 - thorn or nog; 3 - sedimentary gap;

4 - thorn; 5 - nog; 6 - key

Fig. 36

FRAME WALLS PANELS (PANEL WALLS)

Fig. 37.

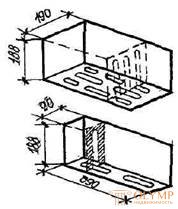

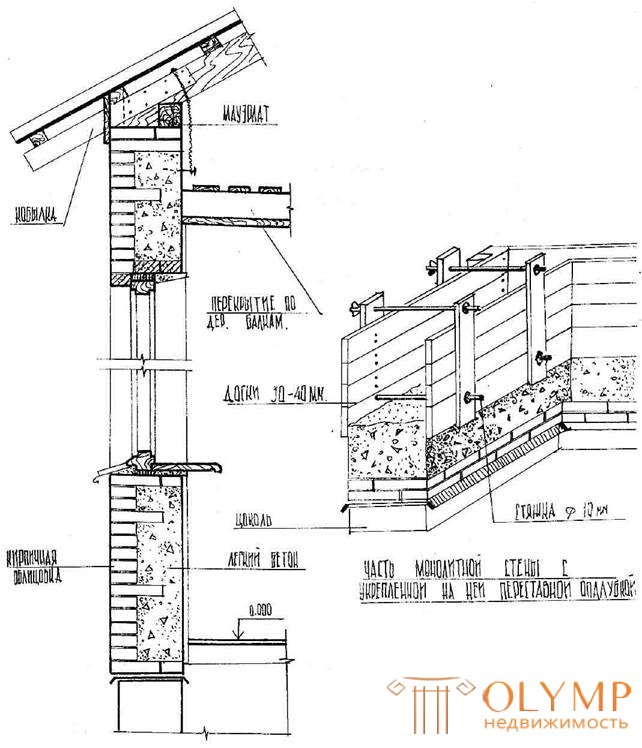

MONOLITH WALLS FROM LIGHT CONCRETE

Fig. 38

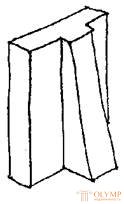

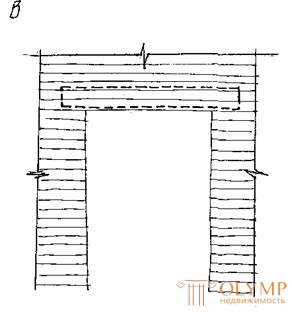

PILASTER

BUTTRESS

SANDRIK

SANDRIK OVER ENTRANCE DOOR

BEAM

HALF-CIRCULAR

TRUNK-THREE-CENTER

FIRED

Fig. 39

IN A SELF-SUPPORTING WALL IN A CARRYING WALL

a, b - jumper team w / b; in - the same with the fixed steel angle

1 - bar lintel; 2 - beam jumper; 3 - profile brick; 4 - steel corner

Fig. 40

WRINKLE WALL

BEADWORKWORK

1 - the direction of the reference plane; 2 - castle brick

STONE EARNINGS

REINFORCED CONCRETE EARTH

Fig. 41

CRANKS

ASPHALT

CONCRETE

CALLS

Fig. 42

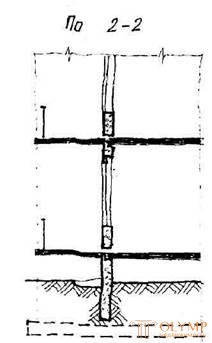

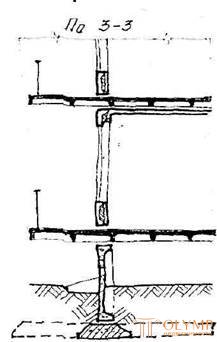

DEFORMATION SEAMS (SEDIMENTARY)

TEMPERATURE SEDIMENTS

SEPARATE SUPPORT

Fig. 42

EXAMPLES OF BALCONY PLATES

a - with pinching in the outer wall; b - on the outer walls and suspension to the transverse inner walls; in - the same, to the eaves; g - to overlappings; d - on external walls and racks; e - on the console;

W - on the attached G - shaped colonnades.

Fig. 43.

BUILT-IN LODGES IN HOUSES

ERKERS

WITH TRANSVERSE WALLS

FOR VOLUME - BLOCK CONSTRUCTIONS

Что бы оставить комментарий войдите

Комментарии (0)