The organization of construction production involves the following areas of scientific and industrial activity: the organization of construction, construction planning and construction management.

The organization of construction is a system for the formation or selection of a production enterprise (complex of enterprises) intended for the performance of the task.

Planning - a system of linking the construction and installation works in time and space, as well as the system of supply and consumption of material and technical resources.

Management is a system of maintaining the established order or transferring building production from one state to another in order to unconditionally accomplish the task.

The main principles of organization, planning and construction management are: centralized management of production and economic activities of construction organizations with the maximum possible expansion of their independence; reducing the time of construction of facilities while improving the quality of construction and installation works and reducing their cost; constant increase in labor productivity; comprehensive mechanization and the fullest possible automation of the building industry; industrialization of production; execution of construction and installation work flow methods; full provision of labor protection and safe performance of work; rational organization of logistics and the economical use of resources; strict adherence to laws and regulations.

The construction of any building or structure of external water supply and sewerage networks and other engineering structures is associated with the production of a complex of building processes by workers of various professions and different qualifications. Construction processes can be carried out continuously or with certain technological breaks. Thus, when laying external sewer networks with socket connections of individual pipelines, prior to hydraulic testing, a certain time is required for hardening the cement mortar in the socket joint. The curing time of the solution in this complex process is a technological break. Technological breaks define more complex conditions for organizing a continuous production process.

Construction processes in space can evolve differently. During the construction of external networks of water supply and sewage, linear processes are observed; in the construction of many-light sewage treatment plants, construction processes are carried out mainly along tiers.

The construction processes are carried out sequentially, in a certain technological dependence (a fragment of trenches, the device of an artificial base, laying pipelines on a given slope, sealing joints, etc.). It is possible to organize work in such a way that a certain team of workers of a certain profession will perform work on the entire route or on the entire construction project and upon their completion will move to another object, and the next team of workers will take its place, which will perform another type of work also on entire track or facility. This method of construction and assembly works is called the sequential method.

With a consistent construction method, each building is erected upon completion of all work at the previous facility. This method of performing work by teams performing various construction processes is accompanied by forced breaks in work.

It is possible to start and finish building processes at all sites simultaneously. At the same time, the construction of all facilities will be equal to the construction time of a single facility, but considerable material and technical resources will be required. This method of construction and assembly works is called the parallel method.

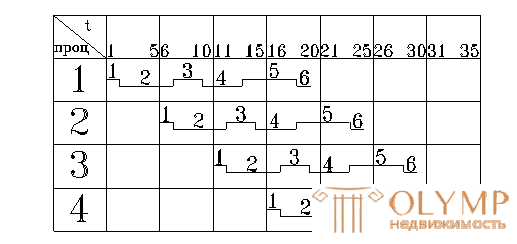

The on-line method of construction and assembly works combines sequential and parallel methods, retaining the advantages of both methods and eliminating the disadvantages of each of them separately. The essence of the flow method can be explained by the following example. Suppose that you want to lay m identical external sewer networks. The main processes for laying each of the networks will be: a fragment of trenches, the device of an artificial base, laying of pipelines in a given direction and a slope with sealing joints, hydraulic testing and backfilling of trenches. As noted above, the execution of these processes occurs sequentially, but it is not at all necessary to wait for the end of one of the processes along the entire route to start the next one. The whole route can be divided into sections called captures, so that on all captures the amount of work when performing basic homogeneous processes was the same. If for the implementation of these amounts of work the number of each brigade is taken to be such that the duration of its work on the capture is also the same, then the number of captures will correspond to the number of main processes in the complex production process. Let us designate the execution time of all the processes of construction of a single network Tts, the main processes performed on the hijackers, in Arabic numerals 1 ... 5 in circles (Fig. 1.1, a).

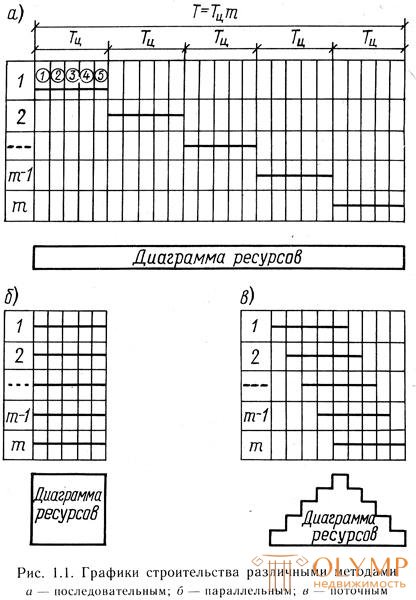

With a consistent method of construction and installation works (Fig. 1.1, a), the time per device m networks will be T = = Tcm, while the intensity of consumption of material and technical resources will be r = R / m (where R is the total cost of construction resources m networks). With the parallel method (Fig. 1.1.6), all networks are constructed simultaneously and the time for their device is equal to the time for the device of one network T = Tc, and the amount of material resources is R = gm.

In the case of construction and assembly works, the flow process (Fig. 1.1, c) is divided into n component processes (in our case, 5), each of which is assigned the same duration and combines their rhythmic execution over time on different networks, providing thus the consistent implementation of homogeneous processes and the parallel execution of heterogeneous. If we take one period of time that corresponds to the performance of work on the 1st network and corresponding to the 5th grab, then we can be sure that the 1st network is backfilling the trench at this time interval, on the 2nd one there is a hydraulic test, on 3 - the laying of pipelines in a given direction and slope with the sealing of the joints, on the 4th - the device of the artificial base under the pipelines and on the 5th - a fragment of the trench. However, each individual process on different networks is performed sequentially.

The construction of m networks by the flow method requires less time (T <Töm) as compared with the sequential one, and the intensity of consumption of material and technical resources is less as compared with the parallel nr <mr.

To organize the construction flow, it is necessary to divide the production process into components, having entrusted their implementation to workers of relevant professions; create a production rhythm and combine in time the production of constituent processes.

The nature of the separation of construction processes is influenced by various conditions of construction: the configuration of facilities, the type of work performed, etc. However, there are concepts of the flow method common to the whole variety of buildings and structures being built. When distributing operations among workers, it is possible to distinguish stream-operational, stream-disassembled and stream-complex ways of conducting work.

Flow-operational method is used in the separation of the production process of operations in one link. The links of one brigade work in a flow-dispersed manner, performing simple processes at a certain capture site. Flow-integrated method is used in the work of complex teams, in which members of the team have several related professions.

Depending on the configuration of construction objects and its influence on the organization of the flow method of construction, there are distinguished flow-linear and flow-capture methods of work. The flow-linear method is used in the construction of extensive structures, which include external networks of water supply and sewage systems. Flow-capture method is rational in the construction of buildings and structures for various purposes, with significant dimensions in height; subdivided into single and multi-tiered.

In construction, an integrated stream is organized, consisting of specialized (private), object and complex streams. The products of the streams are: specialized - finished volumes of certain works; object - finished buildings and structures; integrated - a group of buildings or structures.

Most production processes (not only construction) can be represented in the form of drawings, diagrams, graphs, tables, etc., fairly accurately reflecting the reality of what is happening in these processes. These are models of an ongoing production process. Organization and planning involve the development of models for the implementation of the production process that is developing in time and space. Currently, there is no established classification of modeling methods.

The accumulated experience of modeling the organization of construction processes in time and space (the work of professors V. A. Afanasyev, V. I. Rybalsky, V. M. Vasilyev, and others) allows the development of scientifically based models to formulate the following basic requirements: purposefulness (availability the purpose for which the model is being created); adequacy (compliance with the model object); model completeness (ensuring the solution of all problems of interest to the user); simplicity of the model (ensuring a good understanding of the model, security from solving extraneous tasks and issuing solutions far from the truth); profitability (maximum cost savings on the creation and study of the model); adaptability (the ability to use the model when taking into account various factors).

In the development of the organization, planning and construction management, the most widely used are models in the form of graphs, cyclograms, network models in the form of a graph, and a tabular form of fixing models in the form of matrices.

In the above example, it was assumed to build t of identical external sewer networks. Each of the networks is divided into 5 grips on which heterogeneous work is simultaneously performed. The amount of captures on the same network (building, structure, etc.) is called the work front.

In the flow method of construction and assembly works, homogeneous work is carried out sequentially, and heterogeneous - in parallel. The stream that forms homogeneous work performed sequentially on different fronts is called the private stream. The flow formed by disparate work performed in parallel on one front of work is called the object flow.

The most important principle of construction work is uniformity, year-round. At the same time, the role of specialization is the maximum partitioning of any work into separate technological parts, processes, operations with the task of performing each of these parts by an individual performer.

An in-line method is a method that ensures a planned, rhythmic production of finished products (completed ZiS, types of work) on the basis of continuous and uniform work of a labor complex of constant composition, timely delivery of all necessary material and technical resources.

With a consistent method of performing work, the total time for performing work is increased compared to others, but the need for resources is minimal, with a parallel method of doing work, time is minimal (= 1 cycle), but resource consumption increases dramatically.

The following features are characteristic of the flow method:

1. the division of work on composite processes in accordance with the specialization and qualifications of performers

2. dismemberment of the work front into separate sections (nodes, grabs, plots) to create the most favorable conditions for work by individual performers

3. maximum combination of processes in time (if possible)

General flow design principles

1. the identification of objects close to each other on the ODA, a constructive solution, the technology of their construction

2. dismemberment of the project construction process into separate works, preferably equal or multiple of labor intensity

3. establishing the feasibility of performing work and connecting interrelated works into a common cumulative process and their synchronization, thus achieving continuity of the construction process

4. consolidation of certain types of work for individual teams, sets the sequence of inclusion in the flow of individual objects and the movement of teams in the process of performing work on individual objects

5. calculation of key parameters

All works should be based on the actual amount of resources that can be issued by the relevant construction organization to perform the amount of work on the flow.

Flow classification by structure

Thread name | Thread structure | The nature (type) of finished products |

Complex |

| ready enterprise, microdistrict, quarter |

Object |

| completed object, consolidation work |

Specialized |

| finished works, separate constructions |

Private |

| structural elements, individual works |

Private and specialized streams may have different directions of development.

a.

horizontal development

horizontal development

b.

ascending descending

Vertical

c. mixed development

By the nature of temporary development, flows are classified into:

rhythmic : equal rhythmic

multi-rhythmic

multiple rhythmic

non-rhythmic : with a uniform change in rhythm

with non-uniform change of rhythm

By duration:

- short-term flow (construction of several ZiS)

- long-term flows (long-term plant)

Construction flows, their types and basic parameters

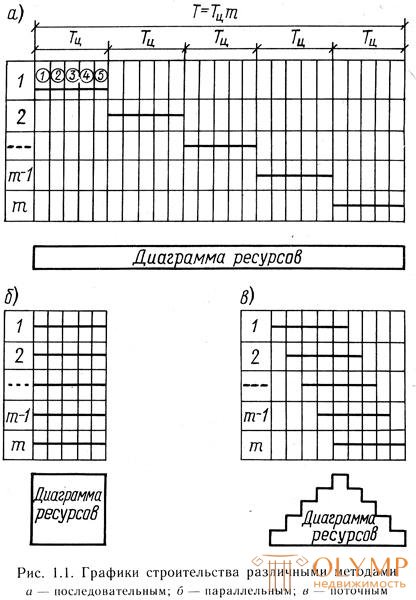

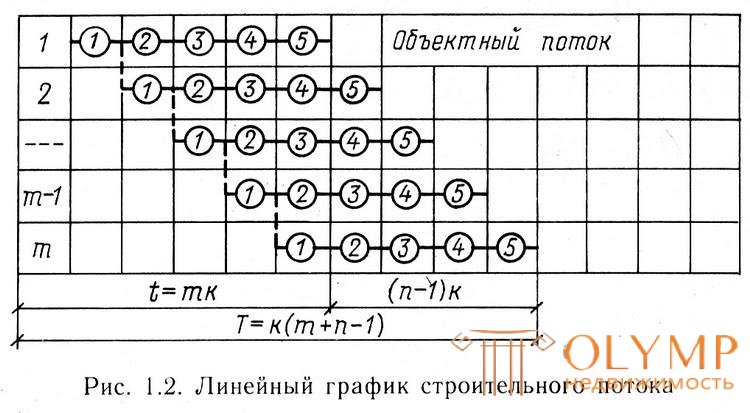

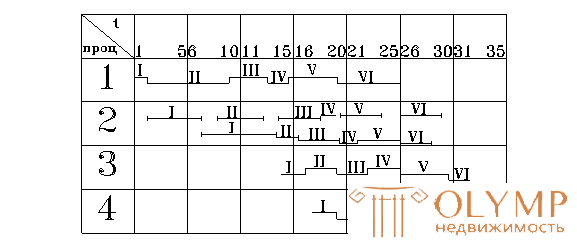

In the stream m buildings are erected, each of which is considered as a capture. The technological process of work production is divided into n component processes or cycles. Processes of the same name form specialized streams, to simplify understanding, all special streams are assumed to be leading and are treated as private, i.e. the most elementary. Work in the private stream is carried out with a certain rhythm, establishing the cyclical nature of the process.

t is the time of one process on all the hooks

t = m * k

T = mk + (n-1) k = k (m + n-1)

T '- time developing flow

T "- time to establish the flow

T "" - the clotting time of the stream

T '= (n-1) k T' '= k (m-n + 1)

T '' '= (n-1) k T = k (m + n-1)

In this case, the continuation of one cycle is the execution time of the private thread on the capture. You can take, for example, the 1st process - the work of the 0th cycle, the 2nd - the construction of walls, etc. Then the cyclical nature of the process will actually be the rhythm of the brigade in the stream, i.e. the duration of each brigade of the amount of work on one capture. The time interval between two adjacent private flows is called the flow pitch k . It indicates the time at which brigades join (pace) into the stream. In this case, the flow pitch is equal to the rhythm of the brigade. Flows in which the rhythms of the teams are constant and equal to the flow pitch are called rhythmic . The duration of the private flow t is determined by the dependence t = m * k and is its main regularity. And the duration of the entire rhythmic flow is determined by the formula T = k (m + n-1).

If the duration of the construction of a single object (the duration of the object flow) is denoted by TTs = n * k, then T = TTs + k ( m -1) . The derived pattern of the construction flow changes when discontinuous construction processes are included in it, i.e. requiring a technical break before the next type of work on the capture. Then the pattern of the construction flow will take the form T = k ( m + n -1) + S Δ t , where SΔt is the total duration of the technological breaks. To preserve the rhythmic flow in such cases, it is necessary to take technological breaks equal to or multiples of the brigade's rhythm (flow pitch).

Work sharing ratio

k sovm = S t / Tf

The coefficient of uneven work

k ner = Nmax / N cf = Nmax / S Q / Tf = Nmax * Tf / S Q

S Q - the complexity of the entire object

From the resource diagram it can be seen that when organizing the flow production of works with a constant rhythm of brigades equal to the flow pitch, the flow construction process consists of three periods:

- deployment of stream T '

- establishing flow T "

- coagulation stream T ""

At first, the stream gradually develops due to the inclusion of new teams of workers and other resources. In the final period, brigades are turned on and, accordingly, reduce resource consumption. The period of establishment of the flow is considered to be such a period in which the flow operates at full capacity, i.e all n building processes are involved in it.

In the practice of construction, there are 3 cases characterizing different degrees of flow. In the 1st case, T '' > 0 0. The flow reaching full capacity is steady in period T '' . In the second case, the stream, having reached almost production capacity, does not acquire a steady state, then T " = 0. A period of development of the flow t or (n-1) k = m * k → n-1 = m. Soin all cases when m = n-1, i.e. the number of all captures (objects) is 1 less than the accepted number of processes or private flows, the steady flow period = 0. In the 3rd case, T '' <0 → m <n-1.

Рассмотрение этих трех случаев позволяет сделать вывод, что только установившаяся форма отвечает требованиям поточности производства. Неустановившийся поток неэффективен, поэтому применение его должно быть ограничено. При назначении числа захваток следует иметь в виду, что минимальное их количество mmin должно быть меньше или равно n+1, т.к. в этом случае сохраняется установившаяся форма потока. Продолжительность может быть разной, в общем случае, чем продолжительность больше, тем эффективнее поток по всем показателям.

При проектировании потоков пользуются также величиной периода выпуска готовой продукции – это период продолжительности завершающего частного потока

Тпр= m * k

называется производственным циклом .

The time in the stream preceding the production cycle is a technological cycle.

Tm = ( n -1) k

The end of the technological cycle indicates the beginning of the production of finished products.

A variety of rhythmic flows are multi-rhythmic flows . The organization of such flows can be caused by special constructive decisions of the object and such a front of work that does not allow establishing a single rhythm of the brigades on the invaders.

In order to maintain the rhythm of the flow, teams are assigned a constant rhythm equal to or a multiple of the flow pitch. In the latter case, the number of concurrently working brigades (units) of one specialty increases, respectively, to a multiple.

When organizing any flow, first of all, they strive to maintain a constant composition of brigades and the continuity of their work, disrupting the rhythm and pitch of the flow.

Irregular flows with uniform rhythm change

seizure | processes 1 2 3 4 | |||

one | 2 | 2 | 2 | 2 |

2 | four | four | four | four |

3 | 3 | 3 | 3 | 3 |

four | four | four | four | four |

five | five | five | five | five |

6 | one | one | one | one |

In order to avoid a gap in the work of teams determine the maximum duration of work on the capture and make a shift on its value.

Irregular flows with non-uniform change of rhythm

I | II | III | IV | V | VI |

| |

one | 2 | 7 | 3 | 2 | five | 6 | 25 |

2 | five | 2 | four | 2 | four | four | 21 |

3 | 3 | 3 | 3 | 2 | five | 3 | nineteen |

four | 3 | 3 | 3 | four | four | one | 18 |

There should be no breaks in the work of the brigades, each brigade works on its own seizure.

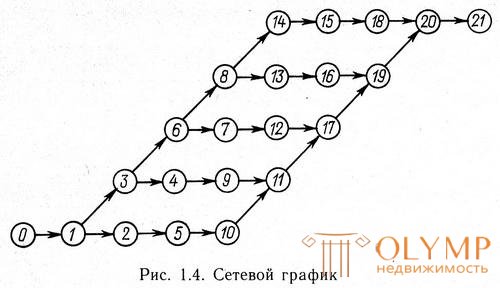

In fig. 1.2 - 1.4 shows the image of the construction flow in the form of a line graph, sequence diagram and network graph.

Что бы оставить комментарий войдите

Комментарии (0)