Knowing how much concrete dries, you can properly plan construction work and optimize the time to complete it without reducing the strength of structures.

Content

When figuring out how much the foundation of a house dries, it is important to understand that besides the usual drying (evaporation of moisture), the floor or other structure made of concrete at this time hardens due to chemical processes occurring in the mixture.

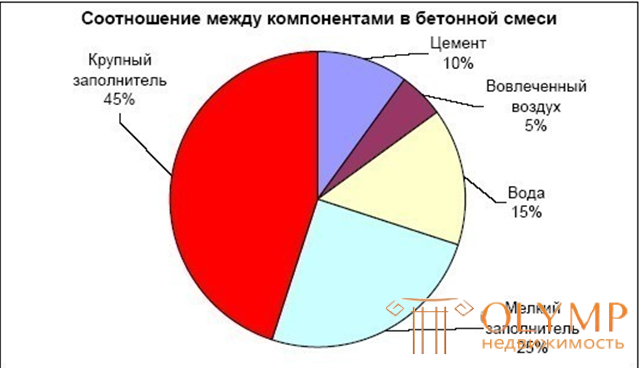

Under the influence of water, the components of the mixture come into closer contact, creating ideal conditions for the hydration or mineralization of the mixture. At this time, the binder component is converted to calcium hydrates and combines all the elements of the composition, including large-fraction (crushed stone, gravel, etc.) into a single monolith.

The composition of concrete mixes.

The ratio between the components of the concrete mix.

Unlike conventional drying, concrete cannot harden faster than technology requires — accelerated loss of moisture will cause not all of the granules of the concrete mix to come into contact with water and react, inside the foundation, block, floor of the house or other structures will remain areas of low strength, bulk and contributing to the rapid destruction of the building as a whole.

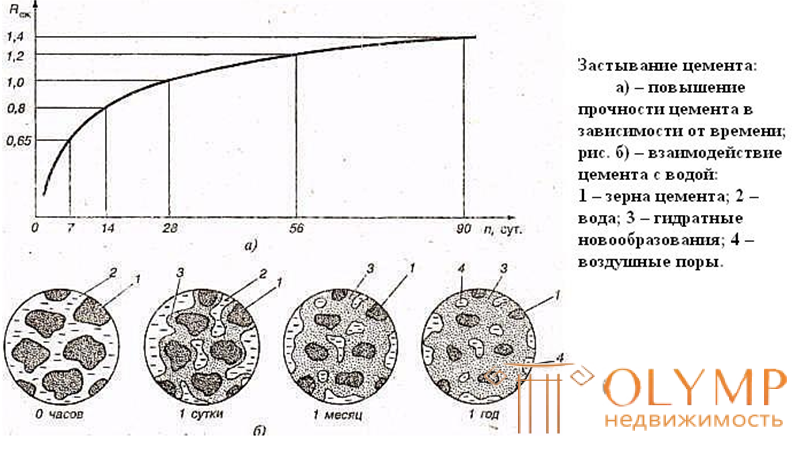

The process of cement hardening.

Accurate calculations of the timing of the set of calculated and maximum strength of concrete are used in the construction of critical objects designed to withstand significant loads, in conditions of time constraints.

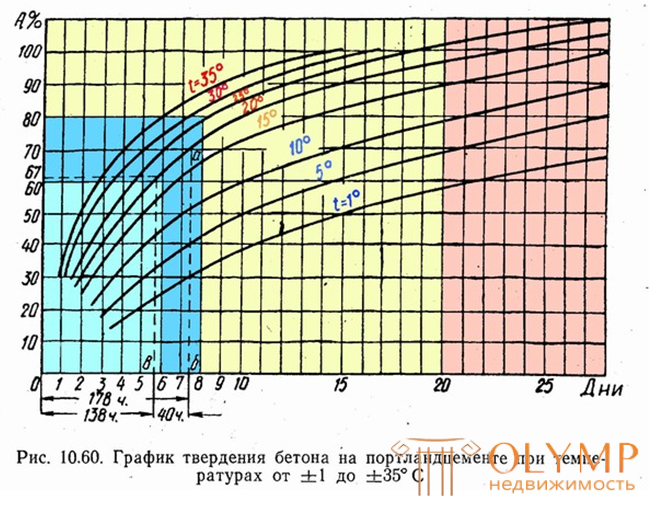

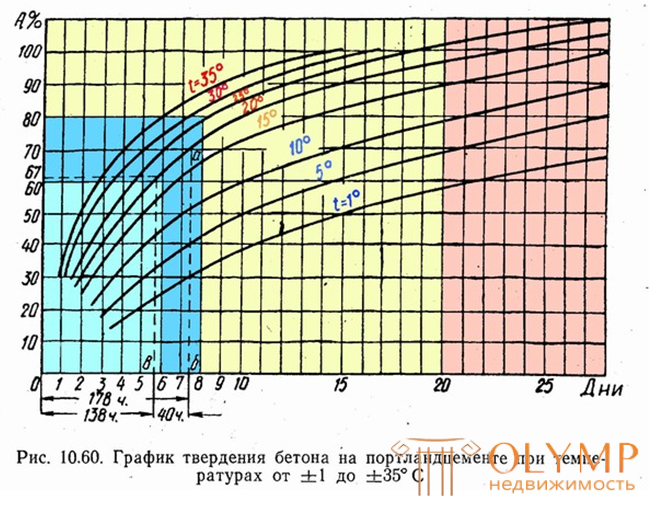

Graph of concrete hardening on Portland cement at different temperatures.

In most cases, in private, commercial and industrial construction, it is considered that the floor or foundation of a house should reach maximum strength after 28 days. This statement requires adjustment - during the specified time (4 weeks) the solution will acquire strength sufficient to withstand the nominal loads. The maximum value in some cases is reached in a few months.

When making small concrete structures of a house that do not experience significant loads, it is allowed to proceed with further construction work 5 days after the mortar is poured, when it sets and it can be walked without danger, the concrete at this stage withstands contact with light objects.

| Time, day | Degree of strength in% of the calculated value |

| 1-3 | 30 or less |

| 7-14 | 60-80 |

| 28 | 100 |

Estimated strength of cement of various grades

| Cement | Strength, kgf / cm² |

| M100 | 98.23 |

| M150 | 130.97-163.71 |

| M200 | 196.45 |

| M250 | 261.93 |

| M300 | 327.42-360.18 |

| M400 | 392.9 |

| M450 | 458.39 |

| M500 | 523.87 |

In the construction of reinforced structures (bridges, transitions, etc.), in addition to the estimated time of strength set-up, such a concept as a control freezing period is used. It is usually 90 days and after this period the concrete should be 20% stronger than a month after pouring.

Often, when pouring mortar under the floor (cement screed) or foundation of a house, a formwork is used, acting as an external frame and preventing spontaneous changes in the geometric parameters of the building until the mortar solidifies.

In addition to the bonding action, formwork prevents intensive loss of moisture by the solution.

There is no need to save the formwork before the expiration of the test of concrete strength. Dismantling is usually possible after the solution is stable enough to maintain its shape.

How long the foundation of a house dries depends on a number of factors:

So, with a decrease in temperature, the curing time of the mixture increases, and already at + 10 ° C, the probability of curing to the calculated value is significantly reduced, therefore, when pouring in cool time and during winter construction, the use of anti-frost additives is recommended.

The question arises, is it possible to speed up the drying process of concrete structures? Such a reduction in terms is possible and practiced under production conditions in the manufacture of concrete goods. In order to increase productivity and increase mold turnover, the curing time is reduced to several days or hours. For this product is subjected to steam treatment. High temperature and intensive contact with heated moisture help to accelerate hydration and gain strength. Increasing the temperature in the domestic environment (for example, if you dry the concrete floor at home) will lead to the opposite result - premature evaporation of water will not allow the cement mixture to fully hydrate, which will reduce its strength.

The use of modifiers allows to accelerate hydration and durability. This method increases the cost of construction, but reduces its time.

In addition to using waterproofing formwork, other methods are used to maintain the required level of humidity:

Optimum freezing conditions:

Other factors influence how the concrete floor will retain moisture during the freezing phase.

Concrete compaction.

Knowing the conditions under which concrete should gain strength, and the calculated values of the characteristics of a certain brand, you can determine how long it will take to create a reliable structure.

«Back When concrete interacts with water, it hardens and becomes a cement stone. However, to influence this process, it is necessary to understand what is happening: how hardening results, what factors it depends on. Studying the stages of hydration allows scientists to create additives for concrete that accelerate the setting and improve its properties. Benefits from the use of additivesEnterprises producing reinforced concrete products or producing ready-mixed concrete use the mentioned additives and get tangible benefits. After all, additives allow:

Stage of concrete setting

At this stage, it is possible to prevent the concrete / cement from finally hardening. After all, the solution still remains mobile, and if it is constantly stirred, the process of setting is delayed - the mechanism of thixotropy acts. Therefore, the solution is delivered in a concrete mixer, carrying out a continuous rotation of the mixture. So its basic properties remain, and the future reliability and durability of concrete / cement does not decrease at all. However, excessive tightening of the rotation time adversely affects the quality characteristics of the concrete / cement. Unfortunately, there are such cases - when force majeure circumstances do not allow pouring the solution into the formwork, and the mixture has to be mixed in concrete mixers for 10-12 hours. Such situations are especially unacceptable in hot weather, because the high temperature of the air contributes to the quick setting of concrete / cement . Continuous rotation does not harden the mixture, however, irreversible changes occur in it, which do not improve performance at all. Stage of curing concreteAs soon as the concrete / cement setting stage is completed, the hardening stage begins. The mixture lies in the formwork, she grabbed and now hardens. Since the regulations spell out the setting time of 28 days, many believe that this is the final term. In fact, the process of hardening and curing of ready-mixed concrete or concrete products has been going on for years. 28 days is a regulated period, which allows the use of concrete products with some guarantee. During these four weeks, the strength of concrete / cement increases very rapidly, and then the increase in hardness occurs at a slow pace. So it turns out thanks to the components which are a part of a mix, providing its hydration. Concrete componentsWhen mixing cement / concrete mortar its main components react with water. At the stages of setting and hardening, their behavior varies considerably. Some ingredients react with the liquid immediately after mixing, others after a while, others do not show any activity at all. Here are the components of the concrete / cement mix:

The role of tricalcium silicate

Triple calcium aluminate - the fastest component C3A (3CaO x Al2O3 formula) works intensively from the very beginning of the setting stage. In the first days of the life of the concrete / cement structure, it contributes to a rapid increase in strength - its reaction rate during the setting period is enormous. But in the stage of hardening and further development of strength, he practically does not participate. Dicalcium silicate - assistant at the stage of hardening C2S (2CaO x SiO2 formula) is inactive for the first four weeks. The setting stage and the initial period of hardening of the cement occur without its participation. By the end of the first month, the activity of his “relative” - tricalcium silicate - is quenched. And dicalcium silicate enters the active phase. Its beneficial effect on the strength of concrete / cement lasts for years, contributing to the increase of this quality. By the way, the “hibernation” period of C2S can be significantly reduced by using special additives in the concrete / cement mix. Inertness of Calcium Alumoferrite C4AF (4CaO x Al2O3 x Fe2O3 formula) is a mineral that plays practically no role in the strength and hardening of concrete / cement. Only at the latest periods of hardening does it affect the increase in structural strength. However, the impact is insignificant. All these components are chemically reacted with mixing. This reaction contributes to the increase, cohesion and precipitation of crystals of minerals, so that the hydration of concrete / cement is the crystallization of the mixture. Improving the quality of concreteNumerous laboratories and institutes study in detail the process of hydration as a whole and its individual stages. Due to this, manufacturers can influence many indicators:

The main role in providing such an impact belongs to special additives in concrete / cement. A modern equipment that performs accurate dosing and thorough mixing, helps to achieve excellent results on the uniformity of the composition of concrete / cement. |

Что бы оставить комментарий войдите

Комментарии (0)