Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

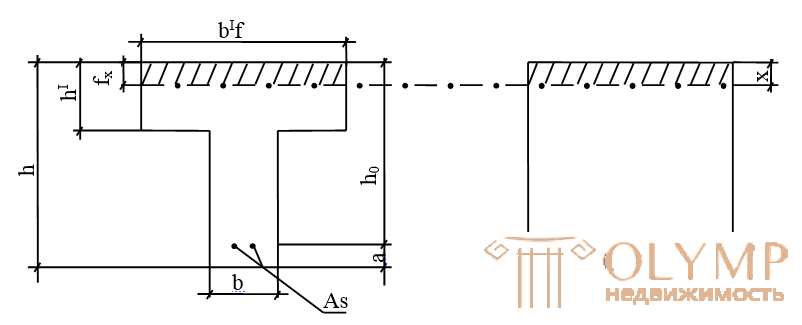

In the first period of the use of reinforced concrete, the overlapping of structures was carried out in the form of solid plates. However, such constructions are not rational, since the height of the compressed zone is 1/10 ... 1/15 of their height, and the stretched zone of the cross-section of concrete is not taken into account in the calculation of strength and serves to accommodate the reinforcement.

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

If part of the concrete is removed from the stretched zone, leaving it only near the reinforcing bars, then a ribbed plate will be obtained. The plate carrying capacity will not change, and the consumption of concrete and the weight of the structure will be significantly reduced. Such elements, called Tauri, are widely used in the form of beams, decking, as a part of monolithic ribbed floors.

Предложить исправление Сохранить Отменить

Experience shows that in areas remote from the edge of the voltage will be less. This is taken into account by the conditional decrease in the width of the overhangs entered into the calculation.

Предложить исправление Сохранить Отменить

1) b'f = b + 12h'f npu h'f

Предложить исправление Сохранить Отменить

2) b'f = b + 6h'f at 0.05 h

Предложить исправление Сохранить Отменить

3) b'f = b with h'f <0.05h

Предложить исправление Сохранить Отменить

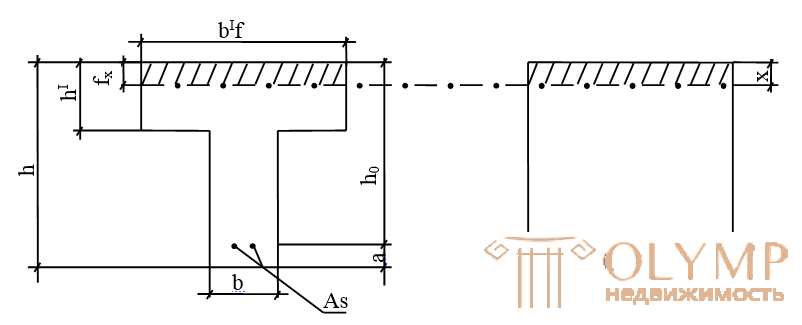

When calculating T-shaped beams, two cases are distinguished: 1. A compressed section area is within a shelf, or below the shelf

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

CASE 1 (x h f ')

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Case 1 occurs in sections with a developed shelf, when the external bending moment is less than or equal to the internal moment perceived by the compressed section shelf relative to the center of gravity of the reinforcement.

Предложить исправление Сохранить Отменить

T-shaped section of this type is calculated as rectangular with dimensions b'f and h, since the area of the stretched concrete does not affect the bearing capacity. For the calculation, the formulas obtained for rectangular section with single reinforcement are used, in which "b" is replaced with "b'f".

Предложить исправление Сохранить Отменить

l. Rb • b'f • x = Rs • As (1)

Предложить исправление Сохранить Отменить

2. M

Предложить исправление Сохранить Отменить

3. M

Предложить исправление Сохранить Отменить

Selection of a T-section can be made, as for a rectangular section according to tabular data using the formulas:

Предложить исправление Сохранить Отменить

4. A0 = M / Rb • b'f • ho2

Предложить исправление Сохранить Отменить

5. As = M /

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

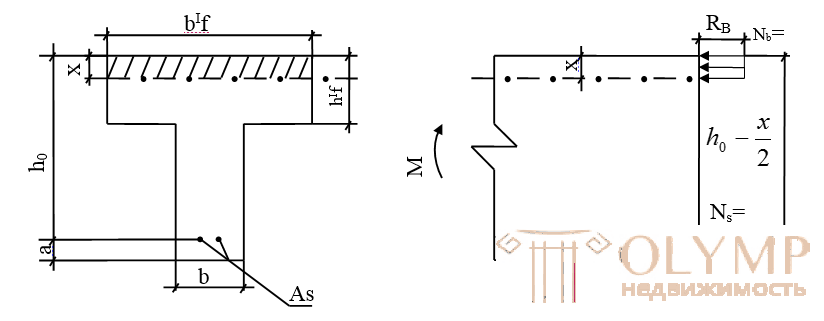

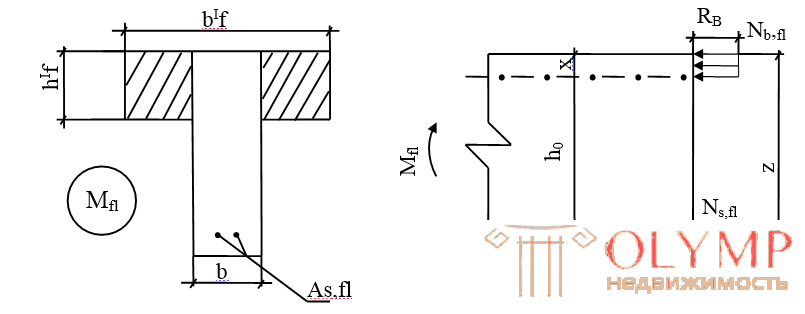

CASE 2 (x> h'f)

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

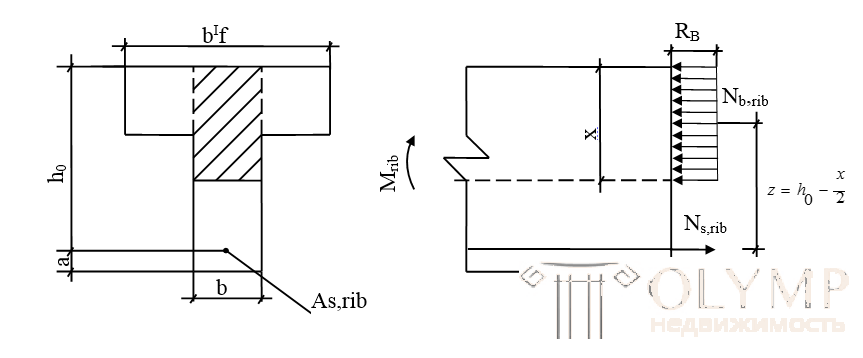

The neutral axis extends beyond the shelf and intersects the edge, (x> h'f), i.e. the external design moment will be greater than the internal moment perceived only by the compressed shelf. Tavrovye sections of this type are found in the calculation of beam structures with a small width of the overhangs of the shelf.

Предложить исправление Сохранить Отменить

To obtain the calculated formulas, the bending moment perceived by the section is divided into two points:

Предложить исправление Сохранить Отменить

but). Mfl - perceived by the shelf overhangs and the corresponding Asfl reinforcement.

Предложить исправление Сохранить Отменить

b). Mrib - perceived by the compressed concrete edges and the corresponding reinforcement As.rib.

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

The concrete of the overhangs of the flange works for compression, and the tension is the corresponding part of the entire reinforcement As.rib. This section takes the moment:

Предложить исправление Сохранить Отменить

6). Mfl = Nb, fl • z = Rb • (b'f-b) • h'f • (ho - h'f / 2) (6)

Предложить исправление Сохранить Отменить

From the condition of equality "0" the sum of the projections of all forces on the element axis:

Предложить исправление Сохранить Отменить

Nb, fl = Nsfl

Предложить исправление Сохранить Отменить

Rb • (b'f-b) • h'f = Rs • As fl, from where

Предложить исправление Сохранить Отменить

7). As fl = Rb • (b'f-b) • h'f / Rs (7)

Предложить исправление Сохранить Отменить

This reinforcement constitutes only a part of the complete reinforcement As, now we will find the rest of the reinforcement corresponding to the reinforcement of the rib As.rib.

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

The rib concrete is working in compression at the height of the compressed zone x, and in tension the rest of the entire tensile reinforcement As.rib.

Предложить исправление Сохранить Отменить

The stress state of this scheme is fully consistent with the stress state of a rectangular section with a height of "h" and a width of "b" with a single reinforcement, which perceives the moment:

Предложить исправление Сохранить Отменить

eight). Mrib = M- Mfl (8)

Предложить исправление Сохранить Отменить

The area of the As.rib reinforcement is defined as for a rectangular section with a single reinforcement width “b”:

Предложить исправление Сохранить Отменить

9). A0 = Mrib / Rb • b • ho2

Предложить исправление Сохранить Отменить

10. As rib = Mrib /

Предложить исправление Сохранить Отменить

The total cross section of tensile reinforcement is determined by the formula:

Предложить исправление Сохранить Отменить

eleven). As = As fl + As.rib (11)

Предложить исправление Сохранить Отменить

Further, according to table 7 of the application, we find the diameter and the number of longitudinal bars required for the reinforcement of the beam.

Предложить исправление Сохранить Отменить

When calculating T-sections, determine which design case (x

Предложить исправление Сохранить Отменить

find the boundary moment MX = h'f = Rb • b'f • h'f • (ho - h'f / 2) (12)

Предложить исправление Сохранить Отменить

If the current moment from external forces M

Предложить исправление Сохранить Отменить

When calculating T-sections, it is most often necessary to solve the problem of determining the cross-sectional area of As reinforcement for given section sizes, material classes and the calculated bending moment "M"

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Decision plan.

Предложить исправление Сохранить Отменить

1. Set the estimated width of the shelf b'f.

Предложить исправление Сохранить Отменить

2. According to the formula (12), calculate Мh = h'f and determine which calculation case the section relates to;

Предложить исправление Сохранить Отменить

3. Find the cross-sectional area of the armature As:

Предложить исправление Сохранить Отменить

3.1 at (x

Предложить исправление Сохранить Отменить

3.2 when (x> h'f) - first determine Mfl by the formula (6) and As fl

Предложить исправление Сохранить Отменить

according to the formula (7). Then Mrib is determined by the formula (8) and As rib by the formula (10), as for a rectangular beam with the width "b". The total cross section of tensile reinforcement is found by the formula (11).

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Type 2 Task

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

If you want to establish the carrying capacity of a given section of the formula (1) determine the height of the compressed zone:

Предложить исправление Сохранить Отменить

X = Rs • As / Rb • b'f

Предложить исправление Сохранить Отменить

If (x

Предложить исправление Сохранить Отменить

according to formula 2:

Предложить исправление Сохранить Отменить

M

Предложить исправление Сохранить Отменить

If x> h'f, then the calculation procedure is as follows:

Предложить исправление Сохранить Отменить

1. Determine As, fl no by the formula (7) and Mfl by the formula 6.

Предложить исправление Сохранить Отменить

2. Find As, rib from formula 11

Предложить исправление Сохранить Отменить

3. Count Mrib, as for a rectangular section with

Предложить исправление Сохранить Отменить

single valve:

Предложить исправление Сохранить Отменить

first determine:

Предложить исправление Сохранить Отменить

x = Rs • As, rib / Rb • b, and then:

Предложить исправление Сохранить Отменить

4. Mrib = Rs • As, rib (ho - x / 2)

Предложить исправление Сохранить Отменить

5. Determine the total moment perceived by the section (its carrying capacity):

Предложить исправление Сохранить Отменить

M = Mfl + Mrib

Предложить исправление Сохранить Отменить

EXAMPLE N1

Предложить исправление Сохранить Отменить

Determine the area of As reinforcement in the element of the T-section according to the following data:

Предложить исправление Сохранить Отменить

M = 42 kNm;

Предложить исправление Сохранить Отменить

Armature class A111

Предложить исправление Сохранить Отменить

Concrete B15;

Предложить исправление Сохранить Отменить

b'f = 80cm; Yi = 1

Предложить исправление Сохранить Отменить

h = 40 cm; h'f = 4 cm;

Предложить исправление Сохранить Отменить

b = 14 cm

Предложить исправление Сохранить Отменить

a = 3cm

Предложить исправление Сохранить Отменить

Decision.

Предложить исправление Сохранить Отменить

According to the tables of the application, we determine the calculated characteristics:

Предложить исправление Сохранить Отменить

Rb = 8.5 • 1 = 8.5mPa; Rs = 365mPa

Предложить исправление Сохранить Отменить

To determine the estimated width of the flange, we find the ratio h'f / h = 4/40 = 0.1– taken b'f = b + 12h'f = 14 + 12 • 4 = 62cm

Предложить исправление Сохранить Отменить

1). Find the useful (working) section height ho = h-a = 40-3 = 37cm

Предложить исправление Сохранить Отменить

2). We calculate the boundary moment Мх = h'f = Rb • b'f • h'f • (ho - h'f / 2) (100) =

Предложить исправление Сохранить Отменить

8.5 • 62 • 4 • (37-4 / 2) • (100) = 7378000nsm = 73.8kNm> 42 kNm, therefore, we have the 1st calculation case.

Предложить исправление Сохранить Отменить

We define As as for a rectangular section of width b'f

Предложить исправление Сохранить Отменить

3) .A0 = M / Rb • b'f • ho2

Предложить исправление Сохранить Отменить

A0 = 42 • 105 / 8.5 • 62 • 372 • (100) = 0.058 <Aomax = 0.42 (tab.5 of the appendix)

Предложить исправление Сохранить Отменить

By A0 we define

Предложить исправление Сохранить Отменить

4). Find As = M /

Предложить исправление Сохранить Отменить

According to table 7 of the application we take 3¯12АIII with As, fact = 3.39 cm2

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

EXAMPLE N2

Предложить исправление Сохранить Отменить

According to the previous example, determine As if M = 86 kNm.

Предложить исправление Сохранить Отменить

Decision.

Предложить исправление Сохранить Отменить

Set the settlement case:

Предложить исправление Сохранить Отменить

Since M> MX = h'f (86> 73.8), we have 2 cases (x> h'f)

Предложить исправление Сохранить Отменить

1). Determine:

Предложить исправление Сохранить Отменить

Mfl = Rb • (b'f-b) • h'f • (ho-h'f / 2) = 8.5 • (62-14) • 4 • (37-4 / 2) (100) = 5712000Nsm = 57.1kNm

Предложить исправление Сохранить Отменить

2). We determine As fl = Rb • (b'f-b) • h'f / Rs = 57.1 • 105/365 • (37-4 / 2) (100) = 4.46 cm2

Предложить исправление Сохранить Отменить

3). We calculate Mrib = M- Mfl = 86-57.1 = 29 kNm

Предложить исправление Сохранить Отменить

4). We calculate A0 = Mrib / Rb • b • ho2

Предложить исправление Сохранить Отменить

A0 = 29 • 105 / 8.5 • 14 • 372 (100) = 0.172 <Aomax;

Предложить исправление Сохранить Отменить

5) .As rib = Mrib /

Предложить исправление Сохранить Отменить

6). We calculate As = As fl + As.rib = 4.46 + 2.39 = 6.85 cm2

Предложить исправление Сохранить Отменить

According to table 7 of the application we take 4¯16АIII with As, fact = 8.04 cm2

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

T-section reinforcement

Предложить исправление Сохранить Отменить

Given: 2¯ 22 ASH L = 7.8m

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Product brand

Предложить исправление Сохранить Отменить

Item Position

Предложить исправление Сохранить Отменить

Name

Предложить исправление Сохранить Отменить

Qty

Предложить исправление Сохранить Отменить

Mass 1det. (kg.)

Предложить исправление Сохранить Отменить

Product weight

Предложить исправление Сохранить Отменить

CR2

Предложить исправление Сохранить Отменить

one

Предложить исправление Сохранить Отменить

¯10АIII L = 1940

Предложить исправление Сохранить Отменить

four

Предложить исправление Сохранить Отменить

1.2

Предложить исправление Сохранить Отменить

5.88

Предложить исправление Сохранить Отменить

2

Предложить исправление Сохранить Отменить

¯3ВР1 L = 980

Предложить исправление Сохранить Отменить

20

Предложить исправление Сохранить Отменить

0.054

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Product brand

Предложить исправление Сохранить Отменить

Item Position

Предложить исправление Сохранить Отменить

Name

Предложить исправление Сохранить Отменить

Qty

Предложить исправление Сохранить Отменить

Mass 1det. (kg.)

Предложить исправление Сохранить Отменить

Product weight

Предложить исправление Сохранить Отменить

KP1

Предложить исправление Сохранить Отменить

one

Предложить исправление Сохранить Отменить

0 22 AIII / = 7780

Предложить исправление Сохранить Отменить

one

Предложить исправление Сохранить Отменить

23.2

Предложить исправление Сохранить Отменить

34.15

Предложить исправление Сохранить Отменить

2

Предложить исправление Сохранить Отменить

0 10A1 / = 7780

Предложить исправление Сохранить Отменить

one

Предложить исправление Сохранить Отменить

4.8

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

08A1 / = 38O

Предложить исправление Сохранить Отменить

41

Предложить исправление Сохранить Отменить

0.15

Предложить исправление Сохранить Отменить

Position

Предложить исправление Сохранить Отменить

Designation

Предложить исправление Сохранить Отменить

Name

Предложить исправление Сохранить Отменить

Count

Предложить исправление Сохранить Отменить

Note

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Assembly units

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

one

Предложить исправление Сохранить Отменить

KPSK 2902 C-32 OSI KR-1

Предложить исправление Сохранить Отменить

skeleton flat KR-1

Предложить исправление Сохранить Отменить

2

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

2

Предложить исправление Сохранить Отменить

KR-2

Предложить исправление Сохранить Отменить

skeleton flat KR-2

Предложить исправление Сохранить Отменить

2

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Details

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

0UA1 / = 18O

Предложить исправление Сохранить Отменить

25

Предложить исправление Сохранить Отменить

0.111

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Materials

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

four

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Concrete B20

Предложить исправление Сохранить Отменить

m3

Предложить исправление Сохранить Отменить

1.17

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Steel consumption statement

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Brand of elements.

Предложить исправление Сохранить Отменить

Reinforcement products

Предложить исправление Сохранить Отменить

Total

Предложить исправление Сохранить Отменить

Armature class

Предложить исправление Сохранить Отменить

Armature class

Предложить исправление Сохранить Отменить

Armature class

Предложить исправление Сохранить Отменить

82,84

Предложить исправление Сохранить Отменить

B1

Предложить исправление Сохранить Отменить

AIII

Предложить исправление Сохранить Отменить

AI

Предложить исправление Сохранить Отменить

BP1

Предложить исправление Сохранить Отменить

GOST 5781-82

Предложить исправление Сохранить Отменить

GOST 5781-82

Предложить исправление Сохранить Отменить

GOST 5781-82

Предложить исправление Сохранить Отменить

022

Предложить исправление Сохранить Отменить

010

Предложить исправление Сохранить Отменить

Total

Предложить исправление Сохранить Отменить

010

Предложить исправление Сохранить Отменить

08

Предложить исправление Сохранить Отменить

Total

Предложить исправление Сохранить Отменить

03

Предложить исправление Сохранить Отменить

Total

Предложить исправление Сохранить Отменить

46.4

Предложить исправление Сохранить Отменить

9.6

Предложить исправление Сохранить Отменить

56

Предложить исправление Сохранить Отменить

12.38

Предложить исправление Сохранить Отменить

12.3

Предложить исправление Сохранить Отменить

24.68

Предложить исправление Сохранить Отменить

2.16

Предложить исправление Сохранить Отменить

2.16

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Questions for self-monitoring on the topic :

Предложить исправление Сохранить Отменить

"The calculation of the bent elements of the T-section"

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

1. What is the advantage of T-shaped sections over rectangular?

Предложить исправление Сохранить Отменить

2. How many cases are there for calculating T-sections?

Предложить исправление Сохранить Отменить

3. How to determine the case of calculating the T-section?

Предложить исправление Сохранить Отменить

4. What is the boundary moment?

Предложить исправление Сохранить Отменить

5. What is the difference between reinforcing a T-section and a rectangular section?

Предложить исправление Сохранить Отменить

6. What are the KR-2 frameworks for in beams of T-section?

Предложить исправление Сохранить Отменить

7. How to determine the diameter and spacing of transverse reinforcement in the frame of the beam?

Предложить исправление Сохранить Отменить

8. Name the types of reinforcement according to the nature of work in the frame of the beam.

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Table 1

Предложить исправление Сохранить Отменить

Design concrete resistance for limiting states of the first group of Rb and Rbt MPa depending on the class of concrete in compressive strength

Предложить исправление Сохранить Отменить

Kind of resistance

Предложить исправление Сохранить Отменить

Concrete

Предложить исправление Сохранить Отменить

Concrete compressive strength class

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

B12.5

Предложить исправление Сохранить Отменить

B15

Предложить исправление Сохранить Отменить

IN 20

Предложить исправление Сохранить Отменить

B 25

Предложить исправление Сохранить Отменить

VZO

Предложить исправление Сохранить Отменить

B 35

Предложить исправление Сохранить Отменить

B40

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Compression oseeoe (prismatic strength) Rb

Предложить исправление Сохранить Отменить

Heavy had a grained

Предложить исправление Сохранить Отменить

7.5

Предложить исправление Сохранить Отменить

8.5

Предложить исправление Сохранить Отменить

11.5

Предложить исправление Сохранить Отменить

14.5

Предложить исправление Сохранить Отменить

17

Предложить исправление Сохранить Отменить

19.5

Предложить исправление Сохранить Отменить

22

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Axial stretch Rbt

Предложить исправление Сохранить Отменить

Heavy

Предложить исправление Сохранить Отменить

0.6

Предложить исправление Сохранить Отменить

0.75

Предложить исправление Сохранить Отменить

0.9

Предложить исправление Сохранить Отменить

1.05

Предложить исправление Сохранить Отменить

1.2

Предложить исправление Сохранить Отменить

1.3

Предложить исправление Сохранить Отменить

1.4

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

table 2

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Calculated resistance fittings for group I of limit states Rs, MPa

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Stretched

Предложить исправление Сохранить Отменить

Compressed rsc

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Type and grade of steel;

Предложить исправление Сохранить Отменить

longitudinal, transverse (clamps and limb) for bending on an inclined section. Rs

Предложить исправление Сохранить Отменить

transverse (clamps and bends) in the calculation of the transverse force

Предложить исправление Сохранить Отменить

Rsw

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Hot rolled round grade A- I

Предложить исправление Сохранить Отменить

225

Предложить исправление Сохранить Отменить

175

Предложить исправление Сохранить Отменить

225

Предложить исправление Сохранить Отменить

: '

Предложить исправление Сохранить Отменить

Hot rolled periodic

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

class profile:

Предложить исправление Сохранить Отменить

A-ll

Предложить исправление Сохранить Отменить

280

Предложить исправление Сохранить Отменить

225

Предложить исправление Сохранить Отменить

280

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

A-III d-8 mm

Предложить исправление Сохранить Отменить

355

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

285

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

355

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

A-III d- 10. ..40 mm |

Предложить исправление Сохранить Отменить

365

Предложить исправление Сохранить Отменить

290

Предложить исправление Сохранить Отменить

365

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Wire reinforcing periodic profile

Предложить исправление Сохранить Отменить

class bp-i

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

.

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

d, mm:

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

375

Предложить исправление Сохранить Отменить

270

Предложить исправление Сохранить Отменить

375

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

four

Предложить исправление Сохранить Отменить

370

Предложить исправление Сохранить Отменить

265

Предложить исправление Сохранить Отменить

365

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

five

Предложить исправление Сохранить Отменить

360

Предложить исправление Сохранить Отменить

260

Предложить исправление Сохранить Отменить

360

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

table 3

Предложить исправление Сохранить Отменить

The ratio between the diameters of the welded rods

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

The diameters of the rods in one direction d1 (mm)

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

four

Предложить исправление Сохранить Отменить

five

Предложить исправление Сохранить Отменить

6

Предложить исправление Сохранить Отменить

eight

Предложить исправление Сохранить Отменить

ten

Предложить исправление Сохранить Отменить

12

Предложить исправление Сохранить Отменить

14

Предложить исправление Сохранить Отменить

sixteen

Предложить исправление Сохранить Отменить

18

Предложить исправление Сохранить Отменить

20

Предложить исправление Сохранить Отменить

22

Предложить исправление Сохранить Отменить

25

Предложить исправление Сохранить Отменить

28

Предложить исправление Сохранить Отменить

32

Предложить исправление Сохранить Отменить

36

Предложить исправление Сохранить Отменить

40

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

The smallest allowable diameters of rods in a different direction d2 (mm)

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

four

Предложить исправление Сохранить Отменить

five

Предложить исправление Сохранить Отменить

five

Предложить исправление Сохранить Отменить

6

Предложить исправление Сохранить Отменить

6

Предложить исправление Сохранить Отменить

eight

Предложить исправление Сохранить Отменить

eight

Предложить исправление Сохранить Отменить

ten

Предложить исправление Сохранить Отменить

ten

Предложить исправление Сохранить Отменить

12

Предложить исправление Сохранить Отменить

12

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

table 4

Предложить исправление Сохранить Отменить

The modulus of elasticity of reinforcing steel Es

Предложить исправление Сохранить Отменить

Type and grade of steel

Предложить исправление Сохранить Отменить

The modulus of elasticity of reinforcement Es.MPa

Предложить исправление Сохранить Отменить

Core steel AI and A-II

Предложить исправление Сохранить Отменить

210,000

Предложить исправление Сохранить Отменить

A-IIIb

Предложить исправление Сохранить Отменить

200,000

Предложить исправление Сохранить Отменить

A-IV, A-VI, AT-IIIC

Предложить исправление Сохранить Отменить

190,000

Предложить исправление Сохранить Отменить

Reinforcing Wire

Предложить исправление Сохранить Отменить

B-II, BP-II,

Предложить исправление Сохранить Отменить

BP-I

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

200,000

Предложить исправление Сохранить Отменить

170,000

Предложить исправление Сохранить Отменить

Reinforcement ropes

Предложить исправление Сохранить Отменить

K-7, K-19

Предложить исправление Сохранить Отменить

180,000

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

table 5

Предложить исправление Сохранить Отменить

Table: Values

Предложить исправление Сохранить Отменить

Reinforcement class

Предложить исправление Сохранить Отменить

Coefficient

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

IN 20

Предложить исправление Сохранить Отменить

VZO

Предложить исправление Сохранить Отменить

B40

Предложить исправление Сохранить Отменить

B50

Предложить исправление Сохранить Отменить

B60

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

AI

Предложить исправление Сохранить Отменить

at

Предложить исправление Сохранить Отменить

0.65

Предложить исправление Сохранить Отменить

0.59

Предложить исправление Сохранить Отменить

0.55

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

AOmax

Предложить исправление Сохранить Отменить

0.48

Предложить исправление Сохранить Отменить

0.42

Предложить исправление Сохранить Отменить

0.4

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

AP

Предложить исправление Сохранить Отменить

at

Предложить исправление Сохранить Отменить

0.62

Предложить исправление Сохранить Отменить

0.57

Предложить исправление Сохранить Отменить

0.52

Предложить исправление Сохранить Отменить

0.47

Предложить исправление Сохранить Отменить

0.44

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

AOmax

Предложить исправление Сохранить Отменить

0.43

Предложить исправление Сохранить Отменить

0.41

Предложить исправление Сохранить Отменить

0.38

Предложить исправление Сохранить Отменить

0.36

Предложить исправление Сохранить Отменить

0.34

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

A-III with ¯

Предложить исправление Сохранить Отменить

6-8 mm

Предложить исправление Сохранить Отменить

at

Предложить исправление Сохранить Отменить

0.59

Предложить исправление Сохранить Отменить

0.54

Предложить исправление Сохранить Отменить

0.5

Предложить исправление Сохранить Отменить

0.44

Предложить исправление Сохранить Отменить

0.41

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

AOmax

Предложить исправление Сохранить Отменить

0.42

Предложить исправление Сохранить Отменить

0.39

Предложить исправление Сохранить Отменить

0.37

Предложить исправление Сохранить Отменить

0.34

Предложить исправление Сохранить Отменить

0.33

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

table 6

Предложить исправление Сохранить Отменить

Coefficient values

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

AO

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

AO

Предложить исправление Сохранить Отменить

0.41

Предложить исправление Сохранить Отменить

0.795

Предложить исправление Сохранить Отменить

0.326

Предложить исправление Сохранить Отменить

0.57

Предложить исправление Сохранить Отменить

0.715

Предложить исправление Сохранить Отменить

0.408

Предложить исправление Сохранить Отменить

0.42

Предложить исправление Сохранить Отменить

0.79

Предложить исправление Сохранить Отменить

0.332

Предложить исправление Сохранить Отменить

0.58

Предложить исправление Сохранить Отменить

0.71

Предложить исправление Сохранить Отменить

0.412

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

0.59

Предложить исправление Сохранить Отменить

0.705

Предложить исправление Сохранить Отменить

0.416

Предложить исправление Сохранить Отменить

0.43

Предложить исправление Сохранить Отменить

0.785

Предложить исправление Сохранить Отменить

0.337

Предложить исправление Сохранить Отменить

0.6

Предложить исправление Сохранить Отменить

0.7

Предложить исправление Сохранить Отменить

0.42

Предложить исправление Сохранить Отменить

0.44

Предложить исправление Сохранить Отменить

0.78

Предложить исправление Сохранить Отменить

0.343

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

0.45

Предложить исправление Сохранить Отменить

0.775

Предложить исправление Сохранить Отменить

0.349

Предложить исправление Сохранить Отменить

0.61

Предложить исправление Сохранить Отменить

0.695

Предложить исправление Сохранить Отменить

0.424

Предложить исправление Сохранить Отменить

0.46

Предложить исправление Сохранить Отменить

0.77

Предложить исправление Сохранить Отменить

0.354

Предложить исправление Сохранить Отменить

0.62

Предложить исправление Сохранить Отменить

0,69

Предложить исправление Сохранить Отменить

0.428

Предложить исправление Сохранить Отменить

0.47

Предложить исправление Сохранить Отменить

0.765

Предложить исправление Сохранить Отменить

0.359

Предложить исправление Сохранить Отменить

0.63

Предложить исправление Сохранить Отменить

0.685

Предложить исправление Сохранить Отменить

0.432

Предложить исправление Сохранить Отменить

0.48

Предложить исправление Сохранить Отменить

0.76

Предложить исправление Сохранить Отменить

0.365

Предложить исправление Сохранить Отменить

0.64

Предложить исправление Сохранить Отменить

0.68

Предложить исправление Сохранить Отменить

0.435

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

0.65

Предложить исправление Сохранить Отменить

0.675

Предложить исправление Сохранить Отменить

0.439

Предложить исправление Сохранить Отменить

0.49

Предложить исправление Сохранить Отменить

0.755

Предложить исправление Сохранить Отменить

0.37

Предложить исправление Сохранить Отменить

0.66

Предложить исправление Сохранить Отменить

0.672

Предложить исправление Сохранить Отменить

0.442

Предложить исправление Сохранить Отменить

0.5

Предложить исправление Сохранить Отменить

0.75

Предложить исправление Сохранить Отменить

0.375

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

0.51

Предложить исправление Сохранить Отменить

0.745

Предложить исправление Сохранить Отменить

0.38

Предложить исправление Сохранить Отменить

0.67

Предложить исправление Сохранить Отменить

0.665

Предложить исправление Сохранить Отменить

0.446

Предложить исправление Сохранить Отменить

0.52

Предложить исправление Сохранить Отменить

0.74

Предложить исправление Сохранить Отменить

0.385

Предложить исправление Сохранить Отменить

0.68

Предложить исправление Сохранить Отменить

0.66

Предложить исправление Сохранить Отменить

0.449

Предложить исправление Сохранить Отменить

0.53

Предложить исправление Сохранить Отменить

0.735

Предложить исправление Сохранить Отменить

0.39

Предложить исправление Сохранить Отменить

0,69

Предложить исправление Сохранить Отменить

0.655

Предложить исправление Сохранить Отменить

0.452

Предложить исправление Сохранить Отменить

0.54

Предложить исправление Сохранить Отменить

0.73

Предложить исправление Сохранить Отменить

0.394

Предложить исправление Сохранить Отменить

0.7

Предложить исправление Сохранить Отменить

0.65

Предложить исправление Сохранить Отменить

0.455

Предложить исправление Сохранить Отменить

0.55

Предложить исправление Сохранить Отменить

0.725

Предложить исправление Сохранить Отменить

0.399

Предложить исправление Сохранить Отменить

_

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

0.56

Предложить исправление Сохранить Отменить

0.72

Предложить исправление Сохранить Отменить

0.403

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

0.01

Предложить исправление Сохранить Отменить

0.995

Предложить исправление Сохранить Отменить

0.01

Предложить исправление Сохранить Отменить

0.21

Предложить исправление Сохранить Отменить

0.895

Предложить исправление Сохранить Отменить

0.188

Предложить исправление Сохранить Отменить

0.02

Предложить исправление Сохранить Отменить

0.99

Предложить исправление Сохранить Отменить

0.02

Предложить исправление Сохранить Отменить

0.22

Предложить исправление Сохранить Отменить

0.89

Предложить исправление Сохранить Отменить

0.196

Предложить исправление Сохранить Отменить

0.03

Предложить исправление Сохранить Отменить

0.985

Предложить исправление Сохранить Отменить

0.03

Предложить исправление Сохранить Отменить

0.23

Предложить исправление Сохранить Отменить

0.885

Предложить исправление Сохранить Отменить

0.203

Предложить исправление Сохранить Отменить

0.04

Предложить исправление Сохранить Отменить

0.98

Предложить исправление Сохранить Отменить

0.039

Предложить исправление Сохранить Отменить

0.24

Предложить исправление Сохранить Отменить

0.88

Предложить исправление Сохранить Отменить

0.211

Предложить исправление Сохранить Отменить

0.05

Предложить исправление Сохранить Отменить

0.975

Предложить исправление Сохранить Отменить

0.048

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

0.06

Предложить исправление Сохранить Отменить

0.97

Предложить исправление Сохранить Отменить

0.058

Предложить исправление Сохранить Отменить

0.25

Предложить исправление Сохранить Отменить

0.875

Предложить исправление Сохранить Отменить

0.219

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

0.26

Предложить исправление Сохранить Отменить

0.87

Предложить исправление Сохранить Отменить

0,226

Предложить исправление Сохранить Отменить

0.07

Предложить исправление Сохранить Отменить

0.965

Предложить исправление Сохранить Отменить

0.067

Предложить исправление Сохранить Отменить

0.27

Предложить исправление Сохранить Отменить

0.865

Предложить исправление Сохранить Отменить

0.236

Предложить исправление Сохранить Отменить

0.08

Предложить исправление Сохранить Отменить

0.96

Предложить исправление Сохранить Отменить

0.077

Предложить исправление Сохранить Отменить

0.28

Предложить исправление Сохранить Отменить

0.86

Предложить исправление Сохранить Отменить

0.241

Предложить исправление Сохранить Отменить

0.09

Предложить исправление Сохранить Отменить

0.955

Предложить исправление Сохранить Отменить

0.085

Предложить исправление Сохранить Отменить

0.29

Предложить исправление Сохранить Отменить

0.855

Предложить исправление Сохранить Отменить

0.248

Предложить исправление Сохранить Отменить

0.1

Предложить исправление Сохранить Отменить

0.95

Предложить исправление Сохранить Отменить

0.095

Предложить исправление Сохранить Отменить

0.3

Предложить исправление Сохранить Отменить

0.85

Предложить исправление Сохранить Отменить

0.255

Предложить исправление Сохранить Отменить

0.11

Предложить исправление Сохранить Отменить

0.945

Предложить исправление Сохранить Отменить

0,104

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

0.12

Предложить исправление Сохранить Отменить

0.94

Предложить исправление Сохранить Отменить

0.113

Предложить исправление Сохранить Отменить

0.31

Предложить исправление Сохранить Отменить

0.845

Предложить исправление Сохранить Отменить

0,262

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

0.32

Предложить исправление Сохранить Отменить

0.84

Предложить исправление Сохранить Отменить

0.269

Предложить исправление Сохранить Отменить

0.13

Предложить исправление Сохранить Отменить

0.935

Предложить исправление Сохранить Отменить

0.121

Предложить исправление Сохранить Отменить

0.33

Предложить исправление Сохранить Отменить

0.835

Предложить исправление Сохранить Отменить

0.275

Предложить исправление Сохранить Отменить

0.14

Предложить исправление Сохранить Отменить

0.93

Предложить исправление Сохранить Отменить

0.13

Предложить исправление Сохранить Отменить

0.34

Предложить исправление Сохранить Отменить

0.83

Предложить исправление Сохранить Отменить

0.282

Предложить исправление Сохранить Отменить

0.15

Предложить исправление Сохранить Отменить

0.925

Предложить исправление Сохранить Отменить

0.13

Предложить исправление Сохранить Отменить

0.35

Предложить исправление Сохранить Отменить

0.825

Предложить исправление Сохранить Отменить

0,289

Предложить исправление Сохранить Отменить

0.16

Предложить исправление Сохранить Отменить

0.92

Предложить исправление Сохранить Отменить

0.147

Предложить исправление Сохранить Отменить

0.36

Предложить исправление Сохранить Отменить

0.82

Предложить исправление Сохранить Отменить

0,295

Предложить исправление Сохранить Отменить

0.17

Предложить исправление Сохранить Отменить

0.915

Предложить исправление Сохранить Отменить

0.155

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

-

Предложить исправление Сохранить Отменить

0.18

Предложить исправление Сохранить Отменить

0.91

Предложить исправление Сохранить Отменить

0.164

Предложить исправление Сохранить Отменить

0.37

Предложить исправление Сохранить Отменить

0.815

Предложить исправление Сохранить Отменить

0.301

Предложить исправление Сохранить Отменить

0.19

Предложить исправление Сохранить Отменить

0.905

Предложить исправление Сохранить Отменить

0.172

Предложить исправление Сохранить Отменить

0.39

Предложить исправление Сохранить Отменить

0.805

Предложить исправление Сохранить Отменить

0.314

Предложить исправление Сохранить Отменить

0.2

Предложить исправление Сохранить Отменить

0.9

Предложить исправление Сохранить Отменить

0.18

Предложить исправление Сохранить Отменить

0.4

Предложить исправление Сохранить Отменить

0.8

Предложить исправление Сохранить Отменить

0.32

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

table 7

Предложить исправление Сохранить Отменить

Cross-sectional areas and mass of reinforcement bars

Предложить исправление Сохранить Отменить

d

Предложить исправление Сохранить Отменить

cross-sectional area (cm.kv.) when the number of rods

Предложить исправление Сохранить Отменить

mass1 m

Предложить исправление Сохранить Отменить

d

Предложить исправление Сохранить Отменить

mm

Предложить исправление Сохранить Отменить

one

Предложить исправление Сохранить Отменить

2

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

four

Предложить исправление Сохранить Отменить

five

Предложить исправление Сохранить Отменить

6

Предложить исправление Сохранить Отменить

7

Предложить исправление Сохранить Отменить

eight

Предложить исправление Сохранить Отменить

9

Предложить исправление Сохранить Отменить

kg

Предложить исправление Сохранить Отменить

mm

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

0.071

Предложить исправление Сохранить Отменить

0.14

Предложить исправление Сохранить Отменить

0.21

Предложить исправление Сохранить Отменить

0.28

Предложить исправление Сохранить Отменить

0.35

Предложить исправление Сохранить Отменить

0.42

Предложить исправление Сохранить Отменить

0.49

Предложить исправление Сохранить Отменить

0.57

Предложить исправление Сохранить Отменить

0.64

Предложить исправление Сохранить Отменить

0.055

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

four

Предложить исправление Сохранить Отменить

0.126

Предложить исправление Сохранить Отменить

0.25

Предложить исправление Сохранить Отменить

0.38

Предложить исправление Сохранить Отменить

0.50

Предложить исправление Сохранить Отменить

0.63

Предложить исправление Сохранить Отменить

0.76

Предложить исправление Сохранить Отменить

0.88

Предложить исправление Сохранить Отменить

1.01

Предложить исправление Сохранить Отменить

1.13

Предложить исправление Сохранить Отменить

0.098

Предложить исправление Сохранить Отменить

four

Предложить исправление Сохранить Отменить

five

Предложить исправление Сохранить Отменить

0.196

Предложить исправление Сохранить Отменить

0.39

Предложить исправление Сохранить Отменить

0.59

Предложить исправление Сохранить Отменить

0.79

Предложить исправление Сохранить Отменить

0.98

Предложить исправление Сохранить Отменить

1.18

Предложить исправление Сохранить Отменить

1.37

Предложить исправление Сохранить Отменить

1.57

Предложить исправление Сохранить Отменить

1.77

Предложить исправление Сохранить Отменить

0.154

Предложить исправление Сохранить Отменить

five

Предложить исправление Сохранить Отменить

6

Предложить исправление Сохранить Отменить

0.283

Предложить исправление Сохранить Отменить

0.57

Предложить исправление Сохранить Отменить

0.85

Предложить исправление Сохранить Отменить

1.13

Предложить исправление Сохранить Отменить

1.42

Предложить исправление Сохранить Отменить

1.70

Предложить исправление Сохранить Отменить

1.98

Предложить исправление Сохранить Отменить

2.26

Предложить исправление Сохранить Отменить

2.55

Предложить исправление Сохранить Отменить

0.222

Предложить исправление Сохранить Отменить

6

Предложить исправление Сохранить Отменить

7

Предложить исправление Сохранить Отменить

0.385

Предложить исправление Сохранить Отменить

0.77

Предложить исправление Сохранить Отменить

1.15

Предложить исправление Сохранить Отменить

1.54

Предложить исправление Сохранить Отменить

1.92

Предложить исправление Сохранить Отменить

2.31

Предложить исправление Сохранить Отменить

2.69

Предложить исправление Сохранить Отменить

3.08

Предложить исправление Сохранить Отменить

3.46

Предложить исправление Сохранить Отменить

0.302

Предложить исправление Сохранить Отменить

7

Предложить исправление Сохранить Отменить

eight

Предложить исправление Сохранить Отменить

0.503

Предложить исправление Сохранить Отменить

1.01

Предложить исправление Сохранить Отменить

1.51

Предложить исправление Сохранить Отменить

2.01

Предложить исправление Сохранить Отменить

2.51

Предложить исправление Сохранить Отменить

3.02

Предложить исправление Сохранить Отменить

3.52

Предложить исправление Сохранить Отменить

4.02

Предложить исправление Сохранить Отменить

4.53

Предложить исправление Сохранить Отменить

0.395

Предложить исправление Сохранить Отменить

eight

Предложить исправление Сохранить Отменить

9

Предложить исправление Сохранить Отменить

0.636

Предложить исправление Сохранить Отменить

1.27

Предложить исправление Сохранить Отменить

1.91

Предложить исправление Сохранить Отменить

2.54

Предложить исправление Сохранить Отменить

3.18

Предложить исправление Сохранить Отменить

3.82

Предложить исправление Сохранить Отменить

4.45

Предложить исправление Сохранить Отменить

5.09

Предложить исправление Сохранить Отменить

5.72

Предложить исправление Сохранить Отменить

0.499

Предложить исправление Сохранить Отменить

9

Предложить исправление Сохранить Отменить

ten

Предложить исправление Сохранить Отменить

0.785

Предложить исправление Сохранить Отменить

1.57

Предложить исправление Сохранить Отменить

2.36

Предложить исправление Сохранить Отменить

3.14

Предложить исправление Сохранить Отменить

3.93

Предложить исправление Сохранить Отменить

4.71

Предложить исправление Сохранить Отменить

5.50

Предложить исправление Сохранить Отменить

6.28

Предложить исправление Сохранить Отменить

7.07

Предложить исправление Сохранить Отменить

0.617

Предложить исправление Сохранить Отменить

ten

Предложить исправление Сохранить Отменить

12

Предложить исправление Сохранить Отменить

1,510

Предложить исправление Сохранить Отменить

2.26

Предложить исправление Сохранить Отменить

3.39

Предложить исправление Сохранить Отменить

4.52

Предложить исправление Сохранить Отменить

5.65

Предложить исправление Сохранить Отменить

6.79

Предложить исправление Сохранить Отменить

7.92

Предложить исправление Сохранить Отменить

9.05

Предложить исправление Сохранить Отменить

10.18

Предложить исправление Сохранить Отменить

0.888

Предложить исправление Сохранить Отменить

12

Предложить исправление Сохранить Отменить

14

Предложить исправление Сохранить Отменить

1.539

Предложить исправление Сохранить Отменить

3.08

Предложить исправление Сохранить Отменить

4.62

Предложить исправление Сохранить Отменить

6.16

Предложить исправление Сохранить Отменить

7,69

Предложить исправление Сохранить Отменить

9.23

Предложить исправление Сохранить Отменить

10.77

Предложить исправление Сохранить Отменить

12.31

Предложить исправление Сохранить Отменить

13.85

Предложить исправление Сохранить Отменить

1,208

Предложить исправление Сохранить Отменить

14

Предложить исправление Сохранить Отменить

sixteen

Предложить исправление Сохранить Отменить

2,011

Предложить исправление Сохранить Отменить

4.02

Предложить исправление Сохранить Отменить

6.03

Предложить исправление Сохранить Отменить

8.04

Предложить исправление Сохранить Отменить

10.05

Предложить исправление Сохранить Отменить

12.06

Предложить исправление Сохранить Отменить

14.07

Предложить исправление Сохранить Отменить

16.08

Предложить исправление Сохранить Отменить

18.10

Предложить исправление Сохранить Отменить

1.578

Предложить исправление Сохранить Отменить

sixteen

Предложить исправление Сохранить Отменить

18

Предложить исправление Сохранить Отменить

2.545

Предложить исправление Сохранить Отменить

5.09

Предложить исправление Сохранить Отменить

7.63

Предложить исправление Сохранить Отменить

10.18

Предложить исправление Сохранить Отменить

12.72

Предложить исправление Сохранить Отменить

15.27

Предложить исправление Сохранить Отменить

17.81

Предложить исправление Сохранить Отменить

20.36

Предложить исправление Сохранить Отменить

22.90

Предложить исправление Сохранить Отменить

1,993

Предложить исправление Сохранить Отменить

18

Предложить исправление Сохранить Отменить

20

Предложить исправление Сохранить Отменить

3.142

Предложить исправление Сохранить Отменить

6.28

Предложить исправление Сохранить Отменить

9.41

Предложить исправление Сохранить Отменить

12.56

Предложить исправление Сохранить Отменить

15.71

Предложить исправление Сохранить Отменить

18.85

Предложить исправление Сохранить Отменить

21.99

Предложить исправление Сохранить Отменить

25.14

Предложить исправление Сохранить Отменить

28.28

Предложить исправление Сохранить Отменить

2.466

Предложить исправление Сохранить Отменить

20

Предложить исправление Сохранить Отменить

22

Предложить исправление Сохранить Отменить

3,801

Предложить исправление Сохранить Отменить

7.60

Предложить исправление Сохранить Отменить

11.40

Предложить исправление Сохранить Отменить

15.20

Предложить исправление Сохранить Отменить

19.00

Предложить исправление Сохранить Отменить

22.81

Предложить исправление Сохранить Отменить

26.61

Предложить исправление Сохранить Отменить

30.41

Предложить исправление Сохранить Отменить

34.21

Предложить исправление Сохранить Отменить

2,994

Предложить исправление Сохранить Отменить

22

Предложить исправление Сохранить Отменить

25

Предложить исправление Сохранить Отменить

4,909

Предложить исправление Сохранить Отменить

9.82

Предложить исправление Сохранить Отменить

14.73

Предложить исправление Сохранить Отменить

19.63

Предложить исправление Сохранить Отменить

24.54

Предложить исправление Сохранить Отменить

29.45

Предложить исправление Сохранить Отменить

34.36

Предложить исправление Сохранить Отменить

39.27

Предложить исправление Сохранить Отменить

44.18

Предложить исправление Сохранить Отменить

3,853

Предложить исправление Сохранить Отменить

25

Предложить исправление Сохранить Отменить

28

Предложить исправление Сохранить Отменить

6.158

Предложить исправление Сохранить Отменить

12.32

Предложить исправление Сохранить Отменить

18.47

Предложить исправление Сохранить Отменить

24.63

Предложить исправление Сохранить Отменить

30.79

Предложить исправление Сохранить Отменить

36.95

Предложить исправление Сохранить Отменить

43.10

Предложить исправление Сохранить Отменить

49.26

Предложить исправление Сохранить Отменить

55.42

Предложить исправление Сохранить Отменить

4.83

Предложить исправление Сохранить Отменить

28

Предложить исправление Сохранить Отменить

32

Предложить исправление Сохранить Отменить

8,043

Предложить исправление Сохранить Отменить

16.08

Предложить исправление Сохранить Отменить

24.13

Предложить исправление Сохранить Отменить

32.17

Предложить исправление Сохранить Отменить

40.21

Предложить исправление Сохранить Отменить

48.25

Предложить исправление Сохранить Отменить

56.30

Предложить исправление Сохранить Отменить

64.34

Предложить исправление Сохранить Отменить

72.38

Предложить исправление Сохранить Отменить

6.313

Предложить исправление Сохранить Отменить

32

Предложить исправление Сохранить Отменить

36

Предложить исправление Сохранить Отменить

10.18

Предложить исправление Сохранить Отменить

20.36

Предложить исправление Сохранить Отменить

30,54

Предложить исправление Сохранить Отменить

40.72

Предложить исправление Сохранить Отменить

50.9

Предложить исправление Сохранить Отменить

61.08

Предложить исправление Сохранить Отменить

71.26

Предложить исправление Сохранить Отменить

81.44

Предложить исправление Сохранить Отменить

91.62

Предложить исправление Сохранить Отменить

7.99

Предложить исправление Сохранить Отменить

36

Предложить исправление Сохранить Отменить

40

Предложить исправление Сохранить Отменить

12.56

Предложить исправление Сохранить Отменить

25.12

Предложить исправление Сохранить Отменить

37.68

Предложить исправление Сохранить Отменить

50.24

Предложить исправление Сохранить Отменить

62,8

Предложить исправление Сохранить Отменить

75.36

Предложить исправление Сохранить Отменить

87.92

Предложить исправление Сохранить Отменить

100.48

Предложить исправление Сохранить Отменить

113.04

Предложить исправление Сохранить Отменить

9.87

Предложить исправление Сохранить Отменить

40

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

CALCULATION OF TARPSETS (TYPE 2) A s =?

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

No. Var

Предложить исправление Сохранить Отменить

M (kNm)

Предложить исправление Сохранить Отменить

in (cm)

Предложить исправление Сохранить Отменить

′ f

Предложить исправление Сохранить Отменить

h′f

Предложить исправление Сохранить Отменить

concrete

Предложить исправление Сохранить Отменить

armature

Предложить исправление Сохранить Отменить

Twi

Предложить исправление Сохранить Отменить

a (cm)

Предложить исправление Сохранить Отменить

h (cm)

Предложить исправление Сохранить Отменить

l (m)

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

one

Предложить исправление Сохранить Отменить

120

Предложить исправление Сохранить Отменить

nineteen

Предложить исправление Сохранить Отменить

60

Предложить исправление Сохранить Отменить

ten

Предложить исправление Сохранить Отменить

B15

Предложить исправление Сохранить Отменить

AII

Предложить исправление Сохранить Отменить

0.8

Предложить исправление Сохранить Отменить

3.0

Предложить исправление Сохранить Отменить

40

Предложить исправление Сохранить Отменить

6.0

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

2

Предложить исправление Сохранить Отменить

123

Предложить исправление Сохранить Отменить

18

Предложить исправление Сохранить Отменить

61

Предложить исправление Сохранить Отменить

eleven

Предложить исправление Сохранить Отменить

IN 20

Предложить исправление Сохранить Отменить

AIII

Предложить исправление Сохранить Отменить

0.85

Предложить исправление Сохранить Отменить

3.2

Предложить исправление Сохранить Отменить

41

Предложить исправление Сохранить Отменить

6.5

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

3

Предложить исправление Сохранить Отменить

136

Предложить исправление Сохранить Отменить

17

Предложить исправление Сохранить Отменить

62

Предложить исправление Сохранить Отменить

12

Предложить исправление Сохранить Отменить

B25

Предложить исправление Сохранить Отменить

AII

Предложить исправление Сохранить Отменить

0.9

Предложить исправление Сохранить Отменить

3.3

Предложить исправление Сохранить Отменить

42

Предложить исправление Сохранить Отменить

6.6

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

four

Предложить исправление Сохранить Отменить

130

Предложить исправление Сохранить Отменить

22

Предложить исправление Сохранить Отменить

63

Предложить исправление Сохранить Отменить

14

Предложить исправление Сохранить Отменить

B30

Предложить исправление Сохранить Отменить

AIII

Предложить исправление Сохранить Отменить

0.85

Предложить исправление Сохранить Отменить

3.4

Предложить исправление Сохранить Отменить

43

Предложить исправление Сохранить Отменить

6.7

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

five

Предложить исправление Сохранить Отменить

124

Предложить исправление Сохранить Отменить

24

Предложить исправление Сохранить Отменить

64

Предложить исправление Сохранить Отменить

15

Предложить исправление Сохранить Отменить

B15

Предложить исправление Сохранить Отменить

AII

Предложить исправление Сохранить Отменить

0.9

Предложить исправление Сохранить Отменить

3.5

Предложить исправление Сохранить Отменить

44

Предложить исправление Сохранить Отменить

6.8

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

6

Предложить исправление Сохранить Отменить

132

Предложить исправление Сохранить Отменить

25

Предложить исправление Сохранить Отменить

65

Предложить исправление Сохранить Отменить

ten

Предложить исправление Сохранить Отменить

IN 20

Предложить исправление Сохранить Отменить

AIII

Предложить исправление Сохранить Отменить

0.8

Предложить исправление Сохранить Отменить

3.6

Предложить исправление Сохранить Отменить

45

Предложить исправление Сохранить Отменить

6.9

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

7

Предложить исправление Сохранить Отменить

118

Предложить исправление Сохранить Отменить

26

Предложить исправление Сохранить Отменить

66

Предложить исправление Сохранить Отменить

eleven

Предложить исправление Сохранить Отменить

B25

Предложить исправление Сохранить Отменить

AII

Предложить исправление Сохранить Отменить

0.85

Предложить исправление Сохранить Отменить

3.7

Предложить исправление Сохранить Отменить

46

Предложить исправление Сохранить Отменить

7.0

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

eight

Предложить исправление Сохранить Отменить

129

Предложить исправление Сохранить Отменить

20

Предложить исправление Сохранить Отменить

67

Предложить исправление Сохранить Отменить

12

Предложить исправление Сохранить Отменить

B30

Предложить исправление Сохранить Отменить

AIII

Предложить исправление Сохранить Отменить

0.9

Предложить исправление Сохранить Отменить

3.8

Предложить исправление Сохранить Отменить

47

Предложить исправление Сохранить Отменить

7.1

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

9

Предложить исправление Сохранить Отменить

137

Предложить исправление Сохранить Отменить

27

Предложить исправление Сохранить Отменить

68

Предложить исправление Сохранить Отменить

13

Предложить исправление Сохранить Отменить

B15

Предложить исправление Сохранить Отменить

AII

Предложить исправление Сохранить Отменить

0.8

Предложить исправление Сохранить Отменить

3.9

Предложить исправление Сохранить Отменить

48

Предложить исправление Сохранить Отменить

7.2

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

ten

Предложить исправление Сохранить Отменить

119

Предложить исправление Сохранить Отменить

28

Предложить исправление Сохранить Отменить

69

Предложить исправление Сохранить Отменить

14

Предложить исправление Сохранить Отменить

IN 20

Предложить исправление Сохранить Отменить

AIII

Предложить исправление Сохранить Отменить

0.85

Предложить исправление Сохранить Отменить

4.0

Предложить исправление Сохранить Отменить

49

Предложить исправление Сохранить Отменить

7.3

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

eleven

Предложить исправление Сохранить Отменить

121

Предложить исправление Сохранить Отменить

29

Предложить исправление Сохранить Отменить

70

Предложить исправление Сохранить Отменить

15

Предложить исправление Сохранить Отменить

B25

Предложить исправление Сохранить Отменить

AII

Предложить исправление Сохранить Отменить

0.9

Предложить исправление Сохранить Отменить

3.0

Предложить исправление Сохранить Отменить

50

Предложить исправление Сохранить Отменить

7.4

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

12

Предложить исправление Сохранить Отменить

127

Предложить исправление Сохранить Отменить

thirty

Предложить исправление Сохранить Отменить

71

Предложить исправление Сохранить Отменить

ten

Предложить исправление Сохранить Отменить

B30

Предложить исправление Сохранить Отменить

AIII

Предложить исправление Сохранить Отменить

0.8

Предложить исправление Сохранить Отменить

3.2

Предложить исправление Сохранить Отменить

40

Предложить исправление Сохранить Отменить

7.5

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

13

Предложить исправление Сохранить Отменить

135

Предложить исправление Сохранить Отменить

15

Предложить исправление Сохранить Отменить

72

Предложить исправление Сохранить Отменить

eleven

Предложить исправление Сохранить Отменить

B15

Предложить исправление Сохранить Отменить

AII

Предложить исправление Сохранить Отменить

0.85

Предложить исправление Сохранить Отменить

3.3

Предложить исправление Сохранить Отменить

41

Предложить исправление Сохранить Отменить

7.6

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

14

Предложить исправление Сохранить Отменить

140

Предложить исправление Сохранить Отменить

sixteen

Предложить исправление Сохранить Отменить

73

Предложить исправление Сохранить Отменить

12

Предложить исправление Сохранить Отменить

IN 20

Предложить исправление Сохранить Отменить

AIII

Предложить исправление Сохранить Отменить

0.9

Предложить исправление Сохранить Отменить

3.4

Предложить исправление Сохранить Отменить

42

Предложить исправление Сохранить Отменить

7.7

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

15

Предложить исправление Сохранить Отменить

141

Предложить исправление Сохранить Отменить

17

Предложить исправление Сохранить Отменить

60

Предложить исправление Сохранить Отменить

13

Предложить исправление Сохранить Отменить

B25

Предложить исправление Сохранить Отменить

AII

Предложить исправление Сохранить Отменить

0.8

Предложить исправление Сохранить Отменить

3.5

Предложить исправление Сохранить Отменить

43

Предложить исправление Сохранить Отменить

7.8

Предложить исправление Сохранить Отменить

Предложить исправление Сохранить Отменить

sixteen

Предложить исправление Сохранить Отменить

142

Предложить исправление Сохранить Отменить

18

Предложить исправление Сохранить Отменить

61

Предложить исправление Сохранить Отменить

14

Предложить исправление Сохранить Отменить

B30

Предложить исправление Сохранить Отменить

AIII

Предложить исправление Сохранить Отменить

1.0

Предложить исправление Сохранить Отменить

3.6